Confused about DTF vs. DTG printing? Explore the pros and cons of each method to determine the ideal printing solution for your business.

What is DTF Printing?

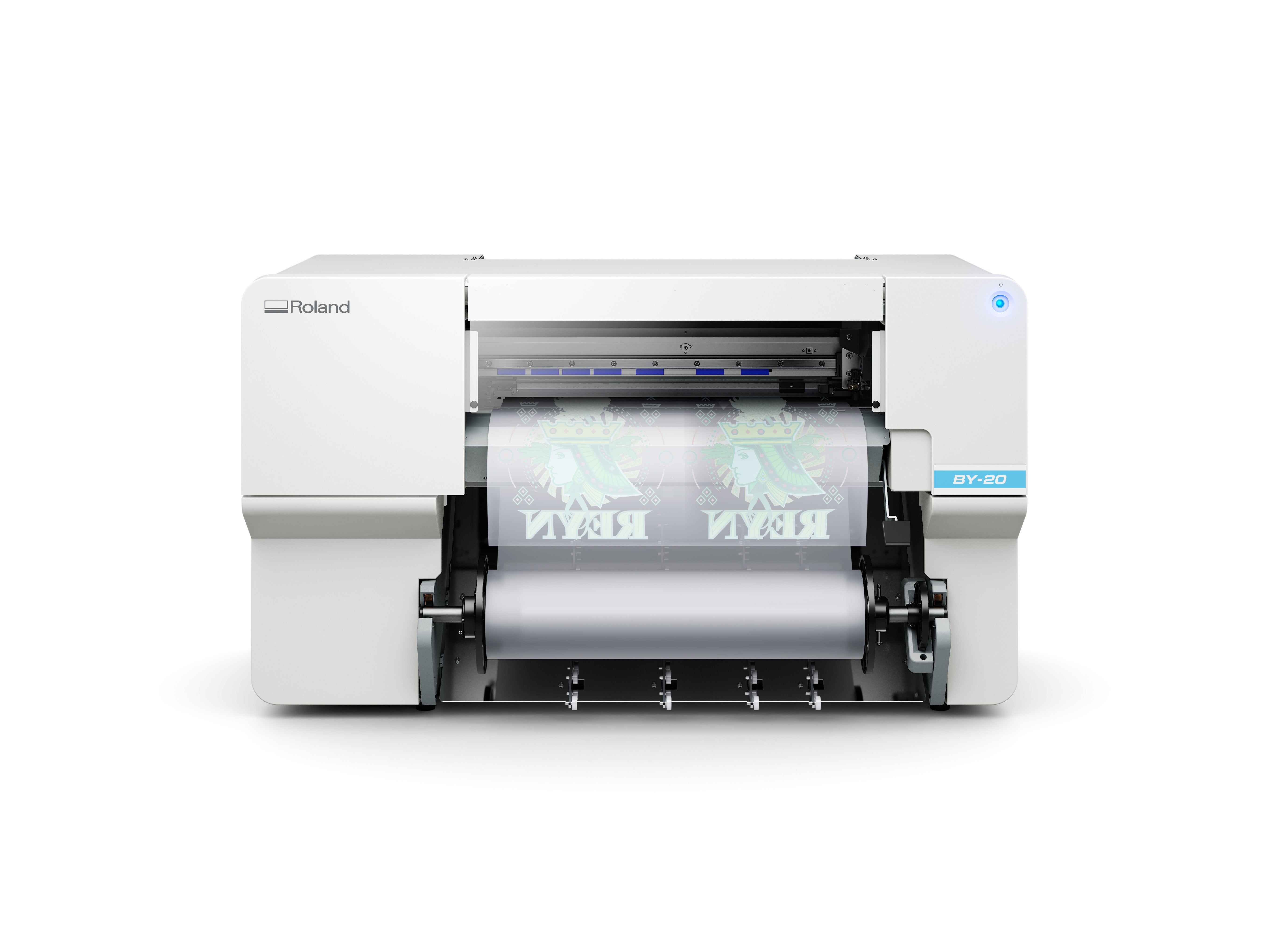

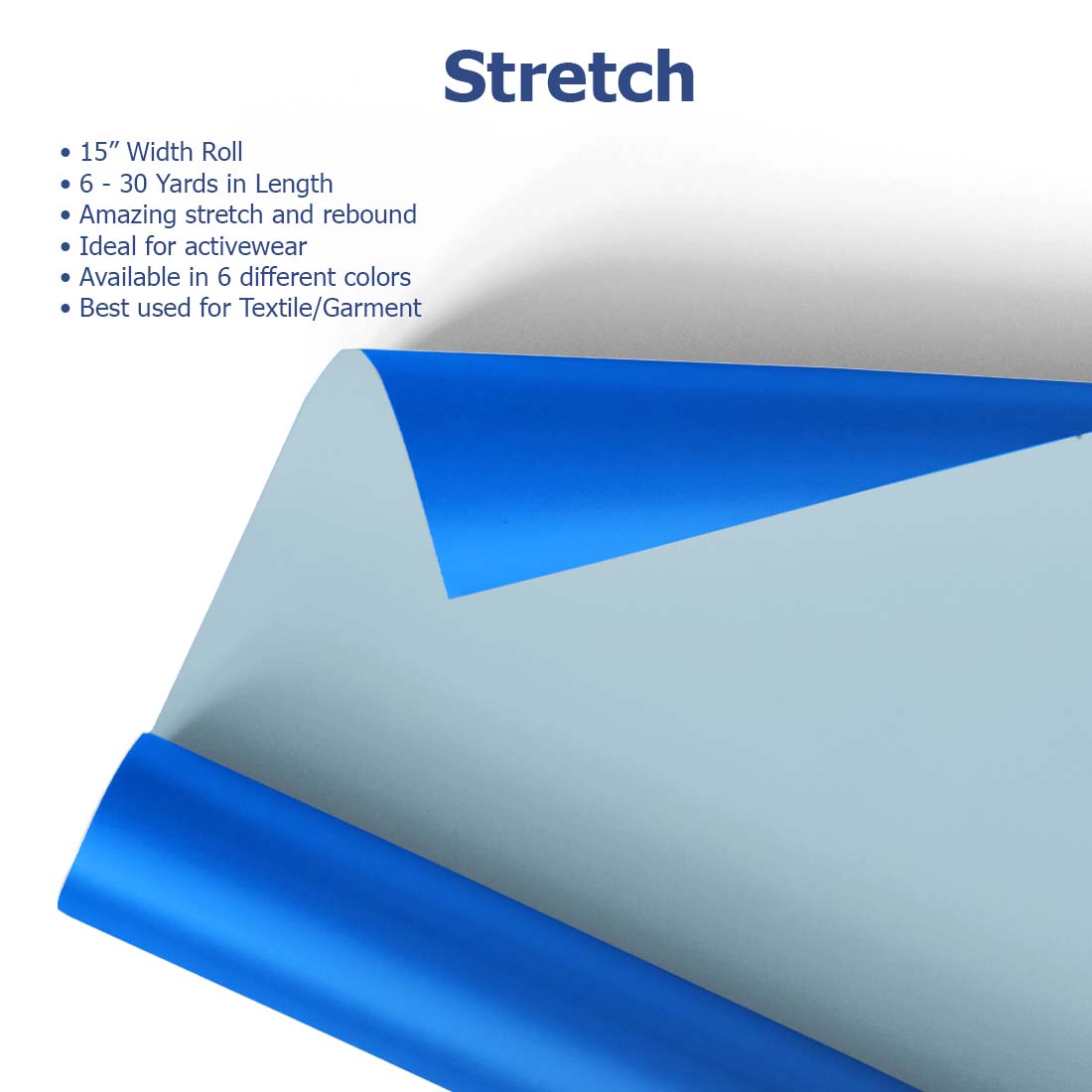

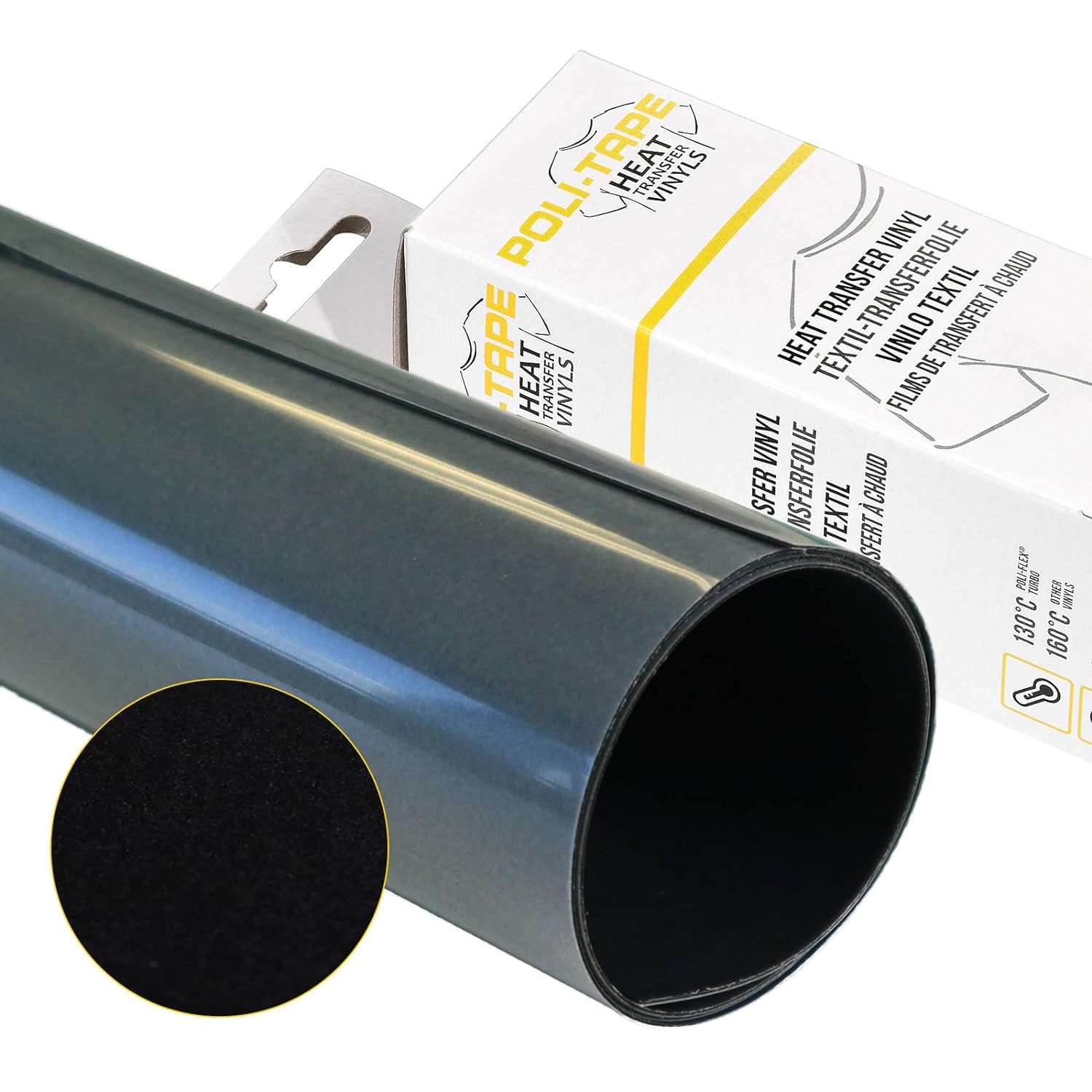

DTF (Direct-To-Film) printing is an innovative method that transfers designs onto garments using a special adhesive film, like Ecofreen® Direct-to-Film (DTF). This process produces high-quality, vibrant prints on a wide range of fabrics, making it ideal for businesses creating custom apparel. DTF is especially suitable for designs with intricate details and multiple colors.

How Does DTF Printing Work?

DTF printing involves several crucial steps that ensure your designs are transferred perfectly onto garments:

-

Step 1: Design Creation

The process begins with creating a digital design using graphic software. This design is then prepared for printing, ensuring all details are crisp and clear. -

Step 2: Printing onto Adhesive Film

The design is printed onto an Ecofreen® Direct-to-Film (DTF) printer. This film acts as the medium that will carry the ink from the printer to the garment. -

Step 3: Applying Hot-Melt Adhesive Powder

After printing, a hot-melt adhesive powder is applied to the wet ink on the film. This powder melts during heat pressing, bonding the ink to the fabric. -

Step 4: Heat Curing

In this stage, the garment and the printed film are placed under a heat press. The heat melts the adhesive powder, which bonds the ink to the fabric's surface, ensuring strong adhesion and vibrant, durable designs. -

Step 5: Peeling Off the Film

After heat pressing, the Ecofreen® DTF film is peeled away, leaving the vibrant design securely adhered to the garment.

When to Choose Direct-To-Film Printing?

DTF printing is ideal for businesses that need fast production and high-quality prints on various fabrics. It’s particularly useful for custom orders and garments that may not be suitable for other methods. DTF works well for intricate designs and multi-color prints.

What is DTG Printing?

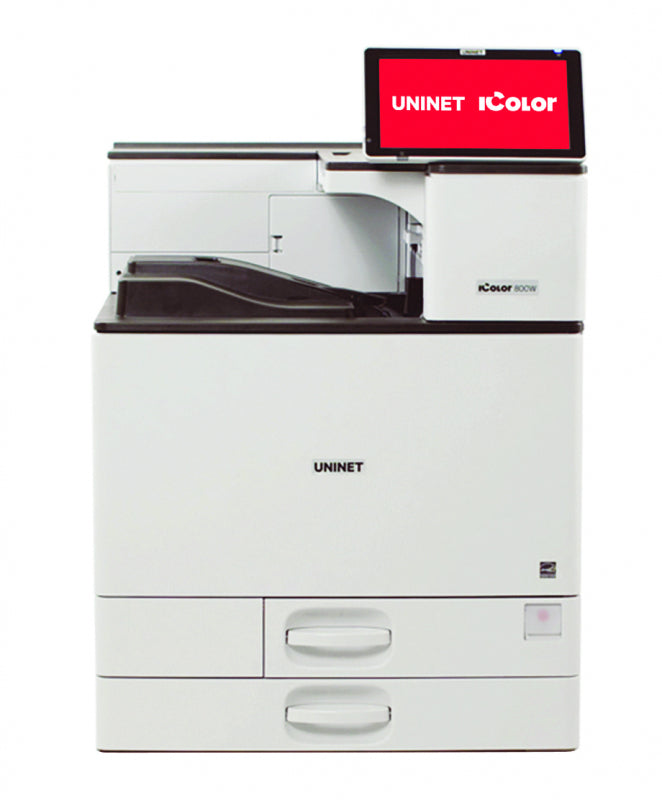

DTG (Direct-To-Garment) printing directly prints designs onto fabric using inkjet technology. Known for producing soft, high-resolution prints, DTG is perfect for custom T-shirts and other apparel, particularly for cotton and cotton-blend fabrics.

How Does DTG Printing Work?

DTG printing involves a straightforward process designed to produce high-quality prints:

-

Step 1: Design Preparation

Begin by preparing the digital design, ensuring it’s optimized for DTG printing. This includes checking color accuracy and resolution. -

Step 2: Pre-treatment (Optional for Dark Garments)

Dark garments require a pre-treatment process to ensure the white ink adheres properly and the colors appear vibrant. -

Step 3: Garment Placement

The garment is placed on the DTG printer's platen, ensuring it’s flat and properly aligned for accurate printing. -

Step 4: Printing Process

The printer applies the design directly onto the garment using specialized inks that penetrate the fabric fibers. -

Step 5: Ink Absorption

After printing, the ink needs a few moments to settle into the fabric, ensuring the print is smooth and vibrant. -

Step 6: Curing Process

The garment is placed under a heat press to cure the ink, making it permanent and durable. -

Step 7: Quality Control

Each garment is inspected to ensure the print quality meets the desired standards. -

Step 8: Final Product

Once all checks are complete, the garment is ready for use or sale, with a print that is vibrant, durable, and soft to the touch.

When to Choose Direct-To-Garment Printing?

DTG printing is perfect for short-run orders, especially when high-quality, detailed designs are required. It’s also ideal for printing on cotton or cotton-blend fabrics. If you’re producing custom apparel with complex color gradients or photo-realistic images, DTG is the go-to method.

DTF vs. DTG: A Print Comparison

When deciding between DTF and DTG, it’s important to consider the unique advantages each method offers. Here’s a side-by-side comparison of DTF and DTG printing to help you decide which method best suits your business:

| Aspect | DTF (Direct-to-Film) | DTG (Direct-to-Garment) |

|---|---|---|

| Print Quality | High-quality, vibrant prints on various fabrics. | Soft, high-resolution prints, especially on cotton. |

| Durability | More durable on a wider range of fabrics, including blends. | Long-lasting on cotton, but may wear faster on other fabrics. |

| Print Complexity | Best for complex, multi-color designs on different fabrics. | Excels in detailed, photo-quality prints on cotton. |

| Fabric Compatibility | Works on cotton, polyester, blends, and more. | Best for cotton and cotton blends. |

| Cost-Effectiveness | More cost-effective for large runs with consistent quality. | Ideal for small orders and one-off custom designs. |

| Maintenance | Generally easier to maintain, but regular care is needed. | Requires regular maintenance, especially for white ink. |

| Eco-friendliness | Moderate waste due to adhesive film. | Lower waste, as ink is applied directly onto the fabric. |

| Upfront Investment | Lower startup costs for the DTF process. | Higher upfront cost for DTG printers. |

DTF vs. DTG: Which Printing Method Should You Choose?

The decision between DTF and DTG ultimately depends on your business's specific needs. If you require versatility across different fabric types, DTF printing may be the best choice. It’s perfect for producing intricate, high-color designs that can be applied to almost any material. On the other hand, if your focus is on high-quality, photo-realistic prints primarily for cotton garments, DTG printing is the ideal method. No matter which method you choose, both offer impressive results with proper care and maintenance.

Conclusion

Both DTF and DTG offer unique advantages for custom garment printing. Whether you need versatility across fabrics or intricate, high-quality designs, Joto has the products and supplies you need for success. Explore our DTF products and DTG products to find the right printing solution for your business today.

Contact us to learn more about DTF and DTG printing solutions.