Choosing the right printing method is essential for achieving high-quality, durable prints in custom apparel and product decoration. Direct to Film (DTF) printing and White Toner Printing are two popular technologies, each offering unique benefits. This guide explores their differences, similarities, and factors to consider to determine which method best suits your business.

DTF Printing and White Toner Printing: Definitions and Distinctions

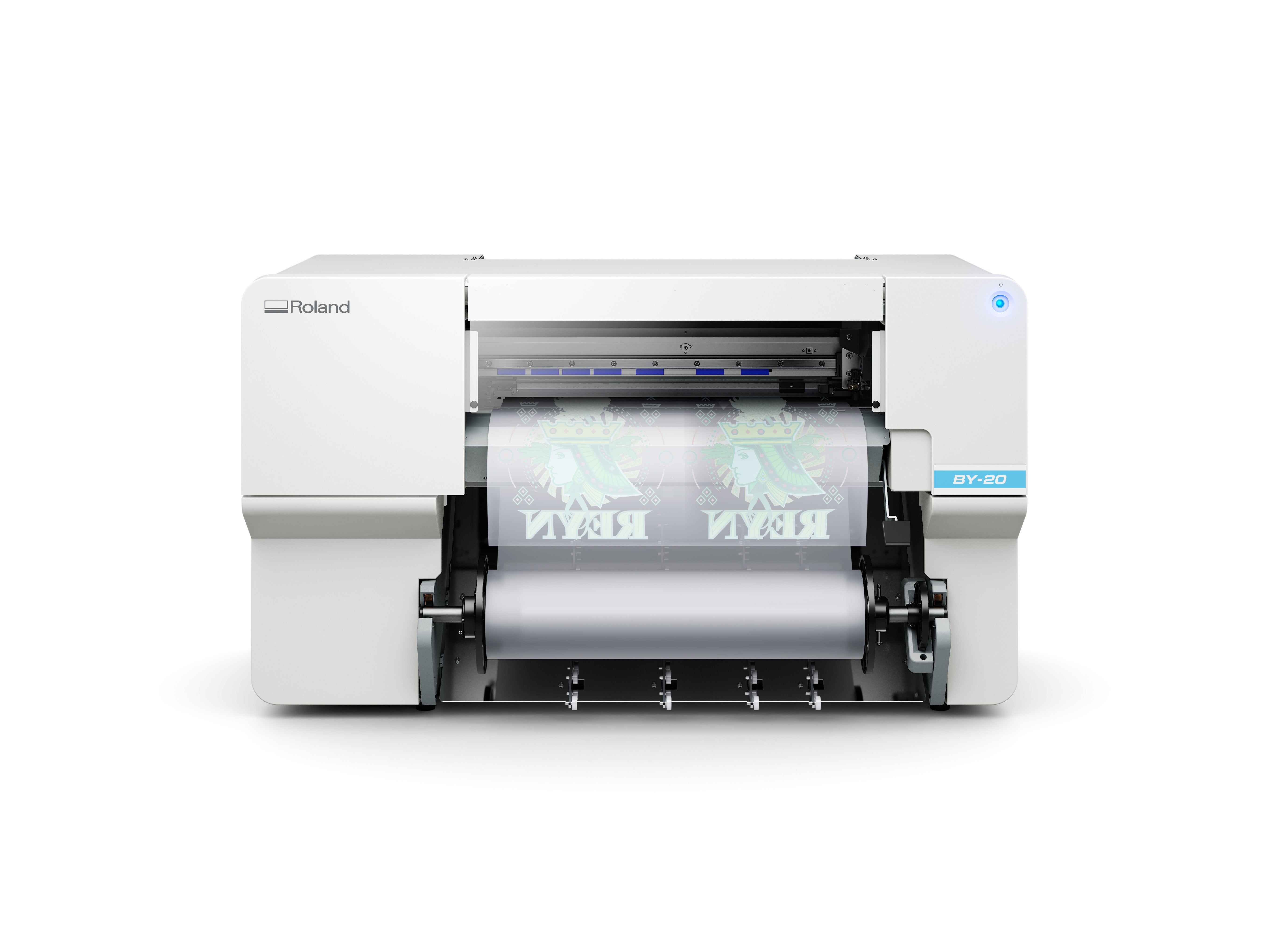

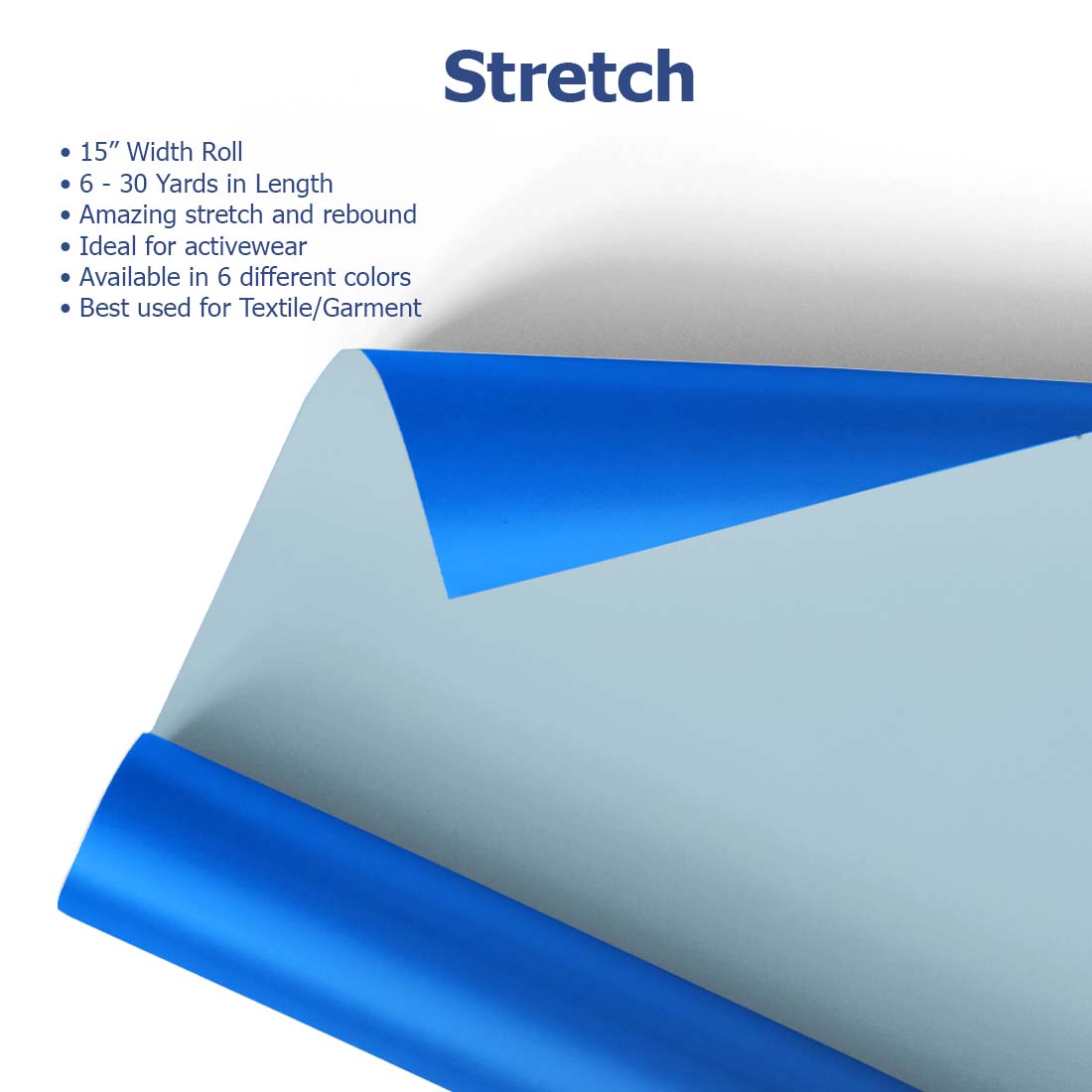

Direct to Film (DTF) Printing is a process where designs are printed onto a specialized film with DTF inks, then transferred to fabrics using adhesive powder and a heat press. This method supports various materials, including cotton, polyester, and blends.

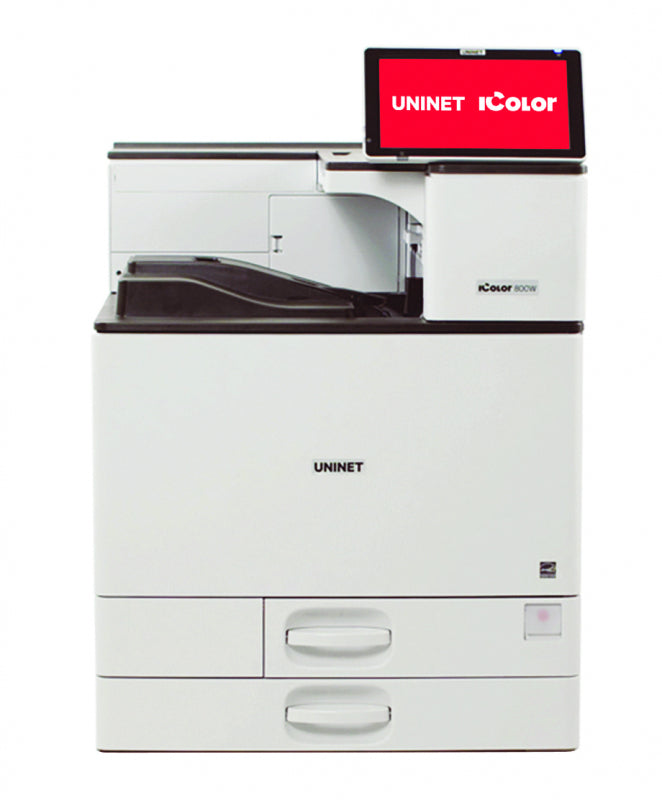

White Toner Printing involves printing designs onto a transfer sheet using a white toner printer. The design can then be applied to substrates like fabrics, ceramics, and other promotional items. This method works directly on the substrate without requiring sublimation blanks, making it a versatile solution for a range of materials, including non-fabric items.

Both methods use heat for image transfer, yet their underlying technologies and material requirements differ, influencing their best applications.

Similarities Between DTF Printing and White Toner Printing

- Versatility: Both DTF and White Toner Printing can be used on a variety of surfaces, including fabric, ceramics, and promotional items. With White Toner, the Pearl Coating™ is essential for ensuring the ink bonds properly to non-fabric items, while DTF uses adhesive powder to bond ink to the fabric.

- Customization Flexibility: Both methods allow for highly customizable, full-color designs with detailed graphics. Whether you’re creating a custom t-shirt or promotional merchandise, both technologies offer excellent color accuracy.

- Durability: Prints from both methods are known for their resistance to cracking, peeling, and fading, ensuring that designs stay vibrant even after multiple washes.

Differences Between DTF Printing and White Toner Printing

- Printing Process: DTF printing involves applying a hot-melt adhesive powder to the design on film, which bonds to the fabric when pressed with heat. White Toner Printing uses a toner-based transfer sheet that requires heat to bond the design to various substrates.

- Materials Compatibility: DTF printing works exceptionally well with various fabric types, such as cotton, polyester, and blends. White Toner Printing offers flexibility across fabrics and certain hard surfaces like ceramics and metals, without needing a sublimation coating.

- Print Vibrancy: White Toner Printing provides vibrant colors on light and dark surfaces, leveraging a white toner layer for high contrast on dark substrates. DTF, with its white underbase, is also vibrant, especially on dark garments.

- Cost Efficiency: DTF printing is typically more cost-effective for smaller to medium runs due to its low setup time and materials cost. White Toner Printing, while versatile, may be more expensive due to the specialized transfer sheets and toners required.

- Maintenance: Both DTF and White Toner printers require regular maintenance. For DTF, this includes maintaining the adhesive powder application and ensuring the printer is cleaned regularly. White Toner printers require upkeep of the toner cartridges and proper calibration of the heat press to ensure consistent results.

Weighing the Pros and Cons: DTF & White Toner Printing in Perspective

DTF Printing Pros:

- Works on a wide range of fabrics.

- Highly durable prints.

- More cost-effective for smaller runs.

DTF Printing Cons:

- Requires a hot-melt adhesive powder for proper transfer.

- May require additional maintenance for smooth operation.

White Toner Printing Pros:

- Works on diverse materials, including fabrics and hard substrates.

- Produces vibrant colors on light and dark surfaces.

- Highly versatile for non-fabric applications.

White Toner Printing Cons:

- Can be more expensive, especially for low-volume projects.

- Vibrancy may not match DTF when printing on dark fabrics.

DTF vs White Toner: What’s Next for Your Business?

Choosing between a DTF printer and a White Toner printer depends on your business needs. For high-quality, durable prints on a variety of surfaces, consider options like the Epson® F2270 Hybrid DTG/DTF Printer from Joto Imaging Supplies. For those interested in White Toner Printing, the iColor 650 White Toner Printer offers an excellent balance of print quality and versatility for promotional products.

When considering the best printer for your business, it’s essential to focus on the types of projects you frequently encounter. Both DTF printers and White Toner printers have their advantages, but the right choice depends on the materials you work with and the production scale of your business.

Explore our full selection of printers and supplies at Joto Imaging Supplies and contact us for personalized assistance in choosing the best option for your business!

Conclusion:

Both DTF and White Toner Printing offer significant benefits for businesses in the custom printing industry. DTF printing may be ideal if you specialize in garments and seek cost-efficient solutions for smaller runs. However, for versatility across fabrics and hard surfaces, White Toner Printing provides flexibility without requiring specialized coatings like sublimation blanks.