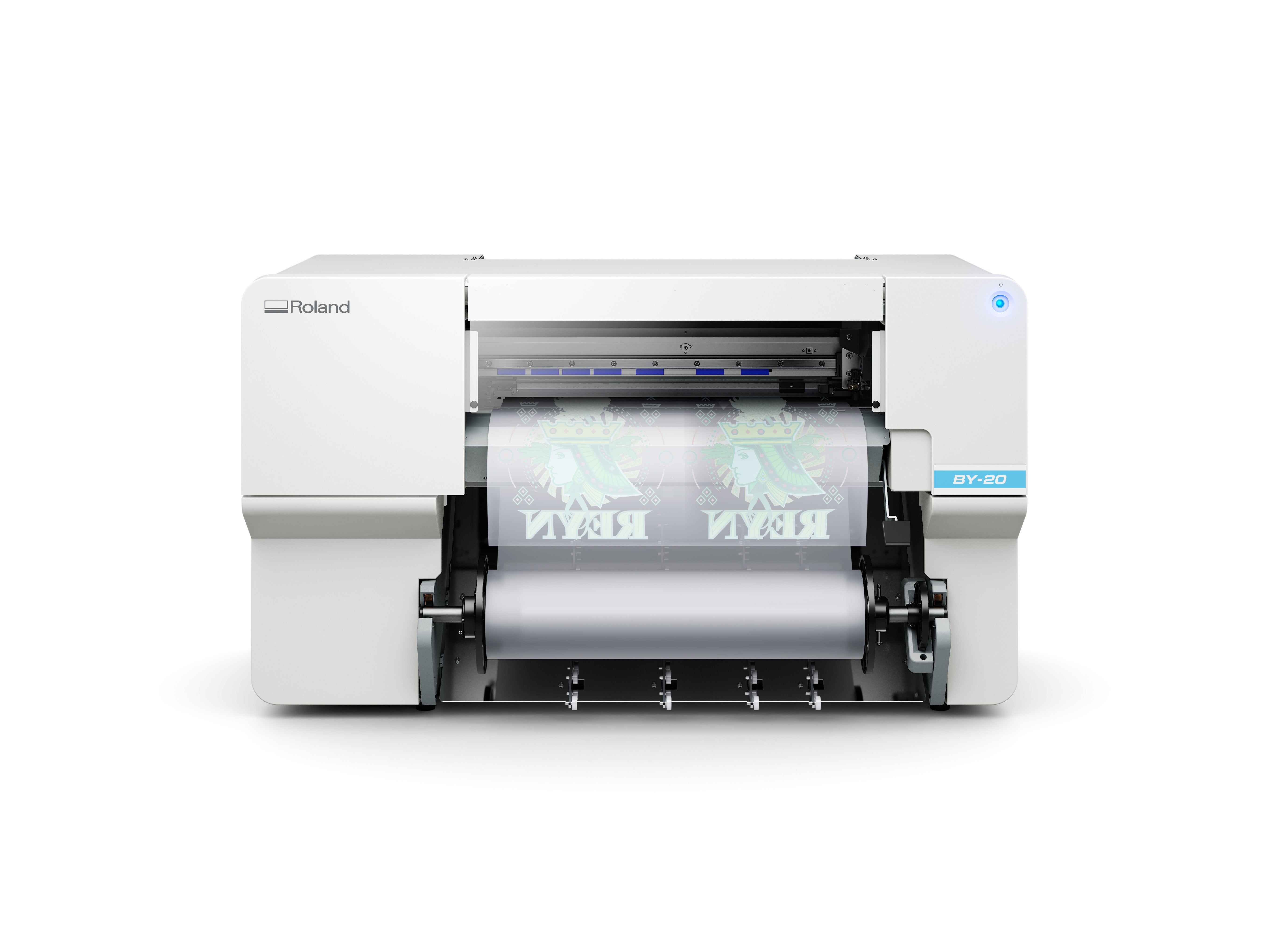

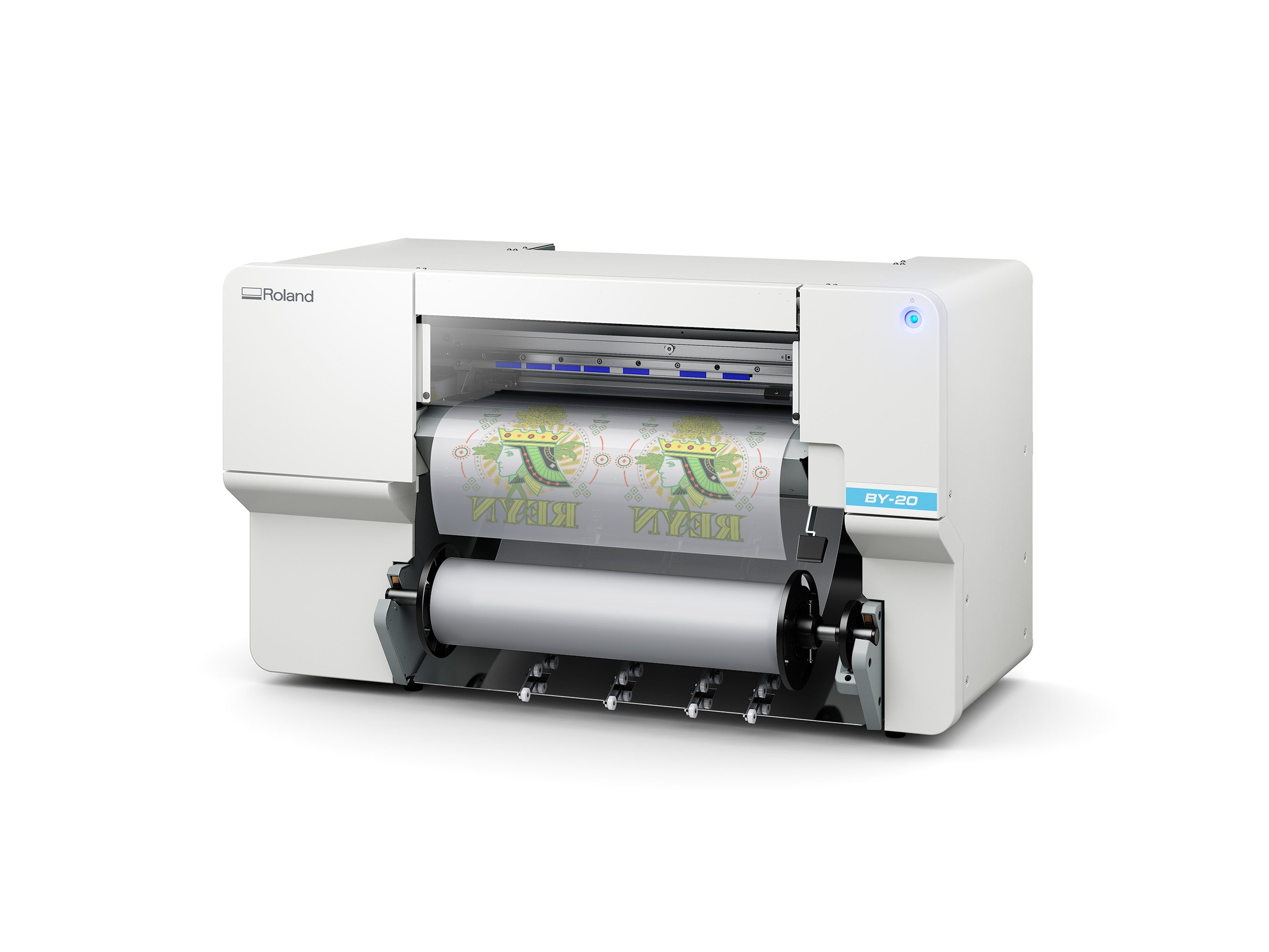

DTF printers that bring designs to life

Joto’s DTF printers offer vibrant colors, durable prints, and efficient workflows, giving shops a powerful solution for producing custom apparel and accessories.

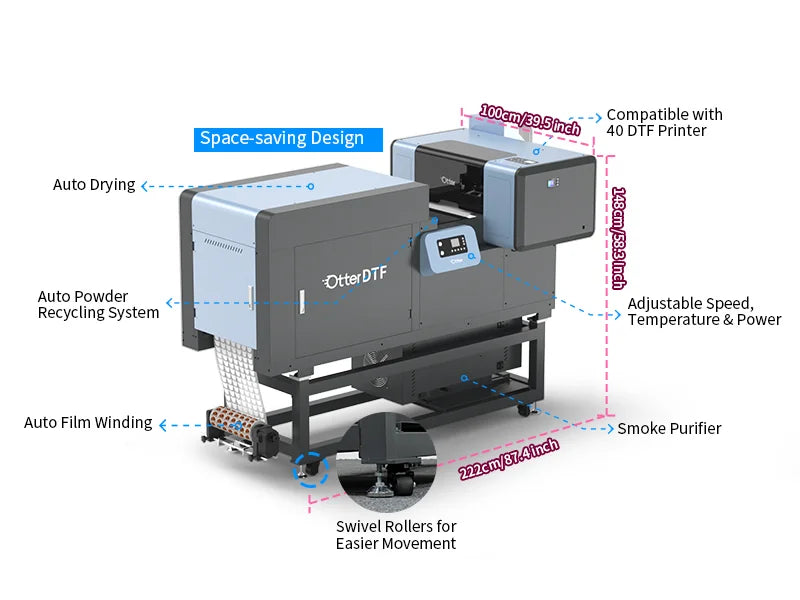

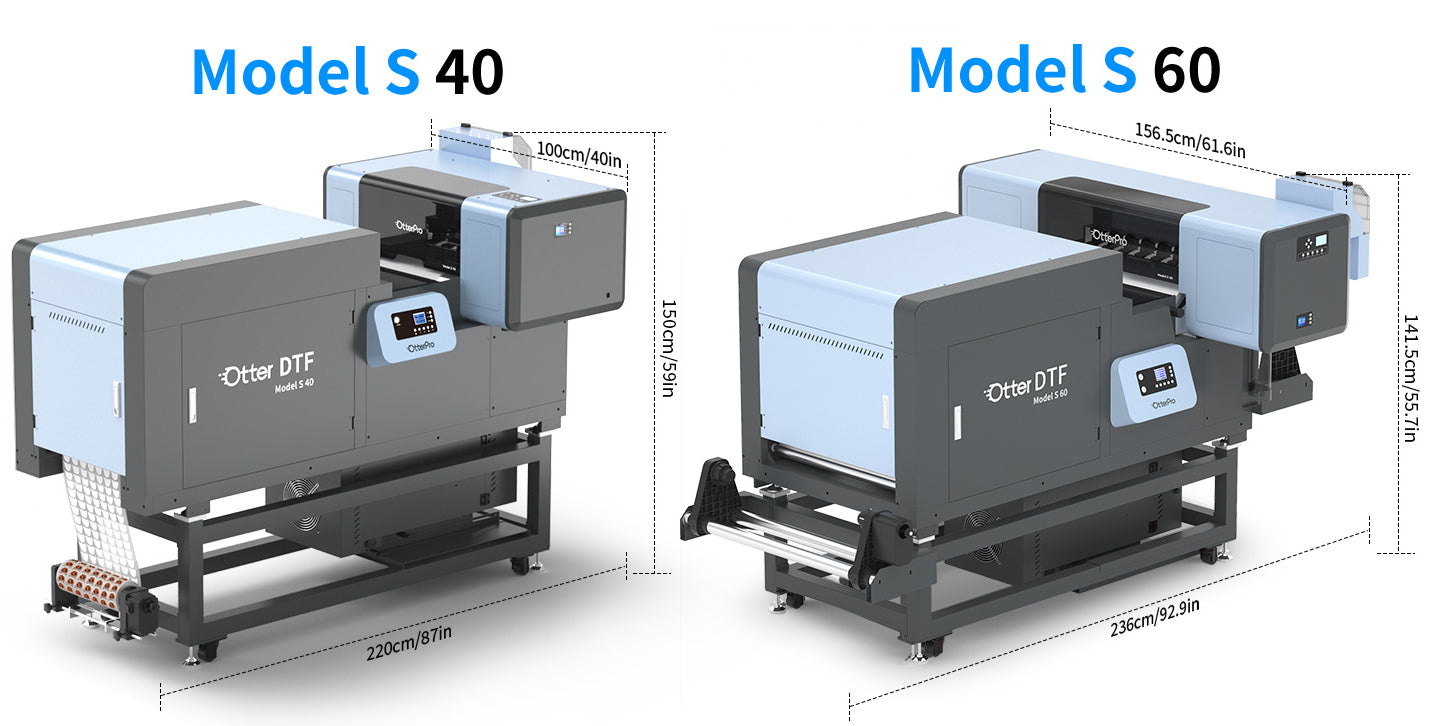

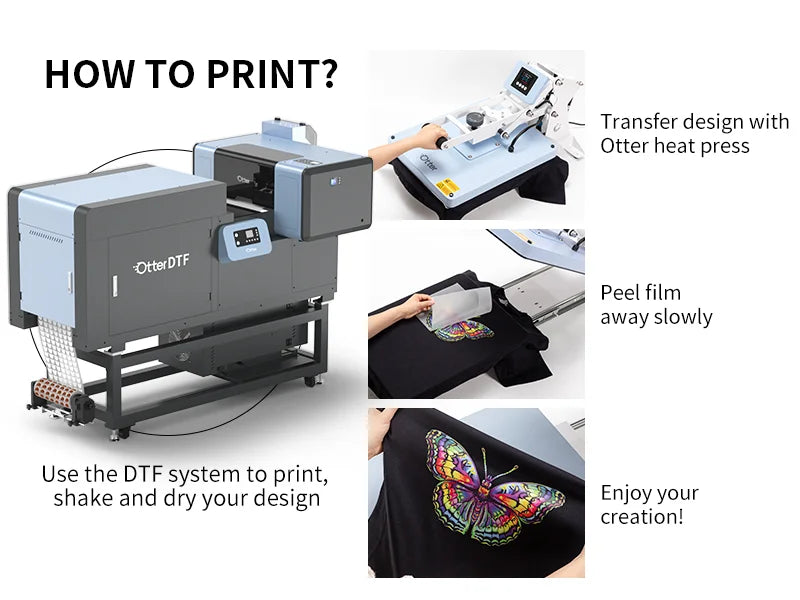

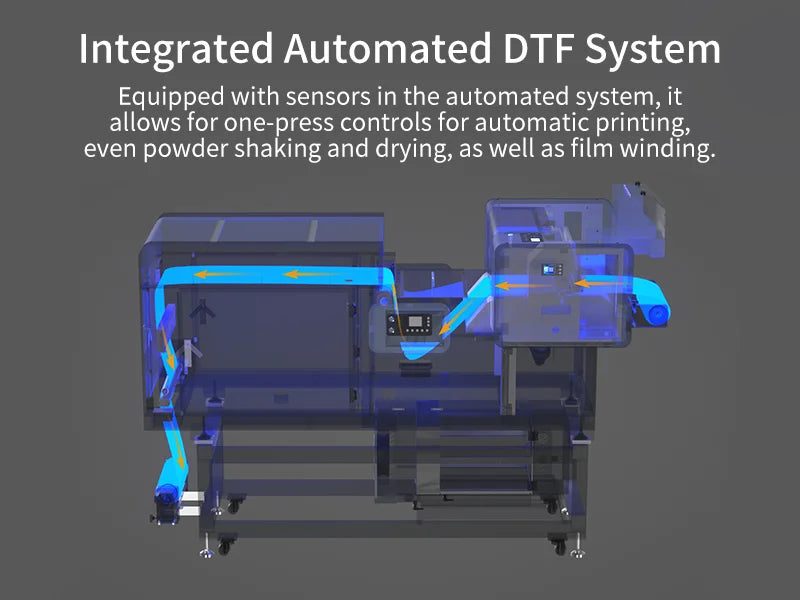

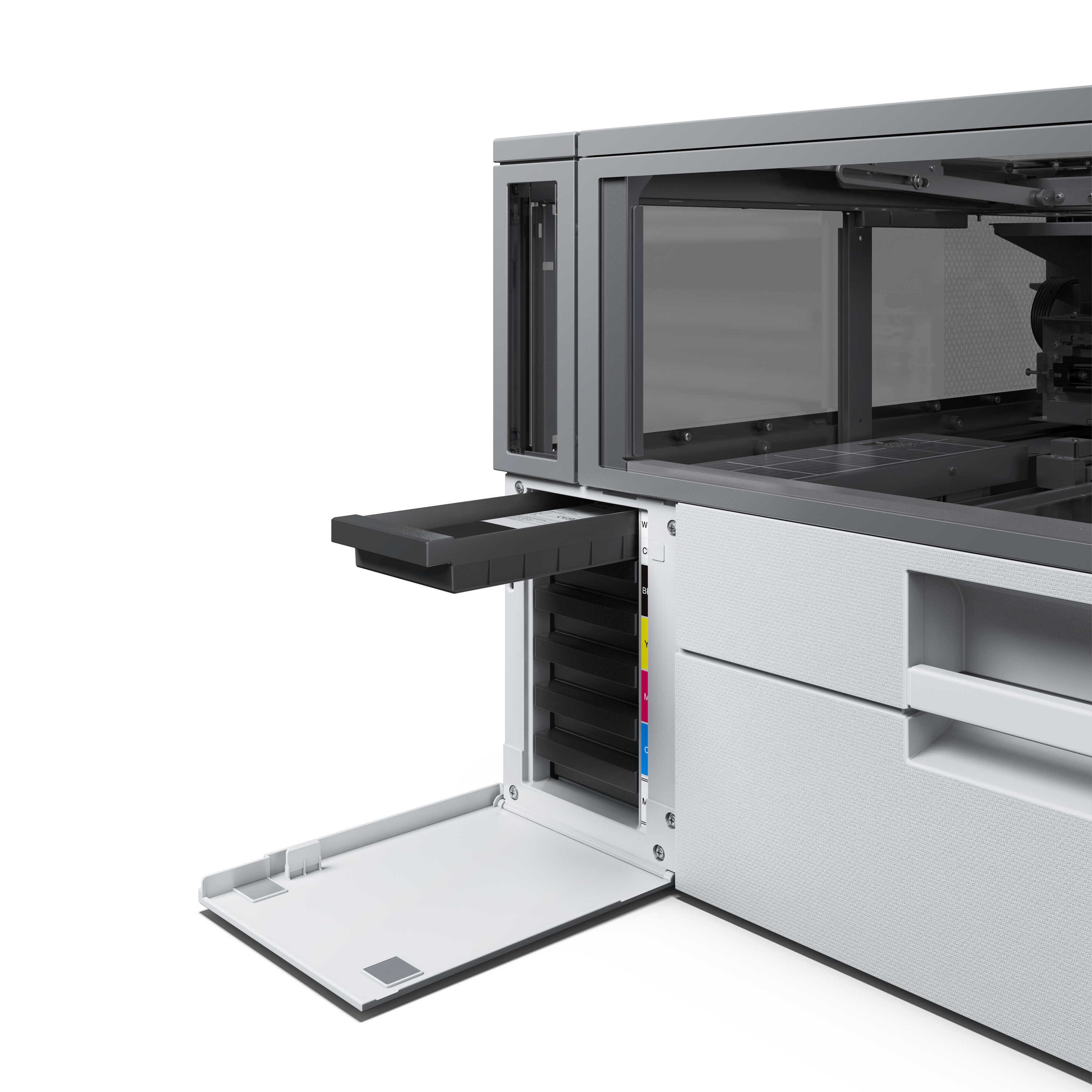

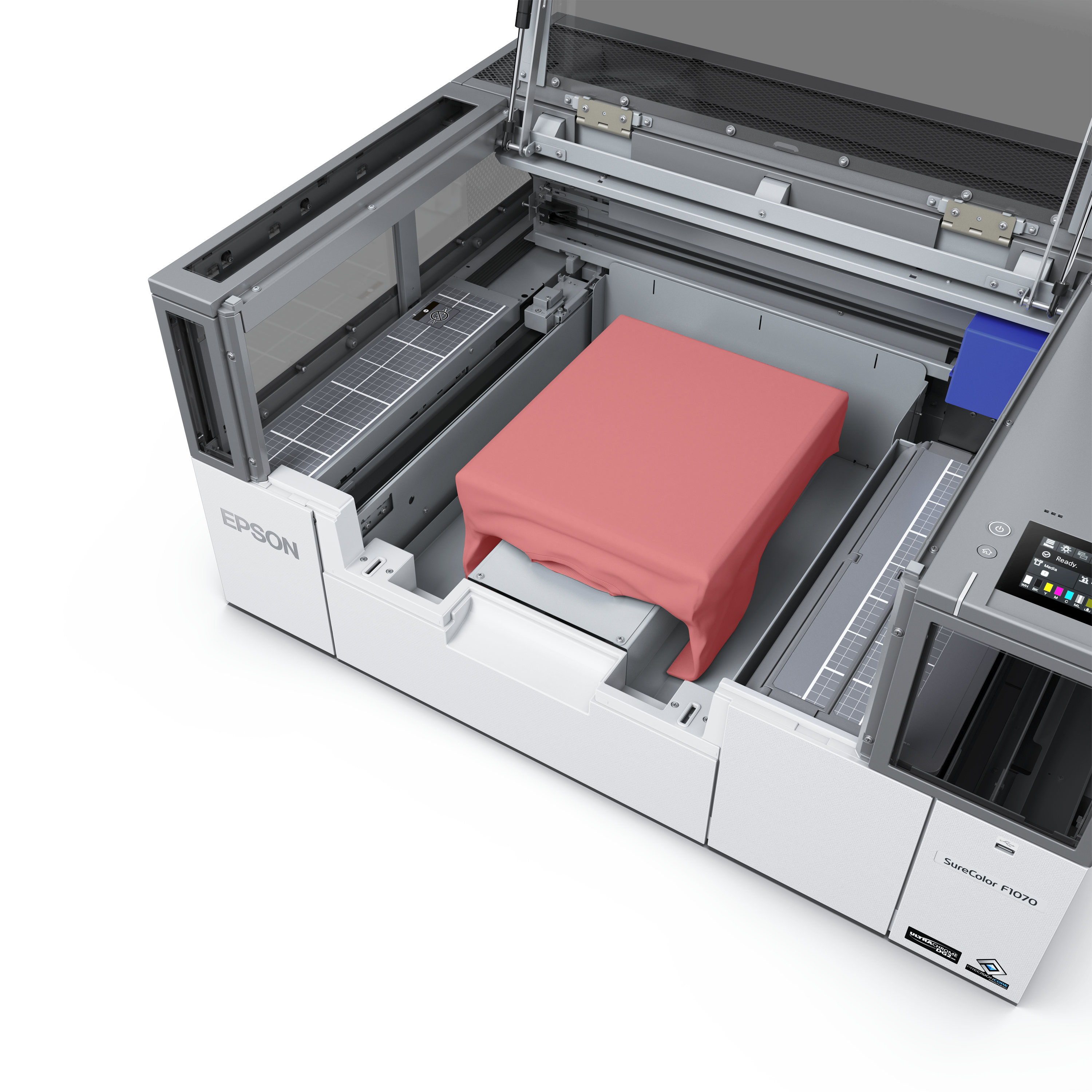

Direct to film technology allows decorators to print full color transfers that adhere to cotton, polyester, blends, and more with outstanding durability. Joto’s lineup of DTF printers is engineered for sharp detail and consistent output, helping shops expand product offerings and meet customer demand. These printers pair seamlessly with Joto DTF inks, powders, and films, ensuring strong wash resistance and long lasting results. Compact options fit smaller spaces, while larger systems handle higher production volumes, making them suitable for businesses of all sizes. Easy to operate and maintain, they reduce wasted materials and improve efficiency with every run. With quick North American shipping and available volume discounts, Joto DTF printers are a smart investment for shops seeking profitability, quality, and growth in today’s competitive market.