High Gloss BOPP Continuous Roll for IColor 250 - Non Die-Cut Labels (4.75"" x 125 ft, 2-Pack)

Transform your product packaging with professional, durable, and eye-catching high-gloss labels. This White Gloss BOPP continuous roll media is specifically engineered for the IColor 250 Inkjet Label Printer, allowing you to produce vibrant, custom-cut, durable labels on demand without the limitations of pre-die-cut stock. Achieve professional results, enhance brand recognition, and ensure your labels withstand tough conditions—all while maximizing your production efficiency.

Key Features

- Premium BOPP Material: Utilizes White Gloss Biaxially Oriented Polypropylene (BOPP), known for superior durability and a smooth, bright white face sheet.

- Continuous Non Die-Cut Format: Provides maximum flexibility for printing custom shapes and sizes using the IColor 250's built-in digital cutter.

- Permanent, General-Purpose Adhesive: Ensures strong, reliable adhesion to a variety of packaging materials, preventing peeling or lifting.

- Water, Oil, and Chemical Resistant: The material is highly resistant to moisture, oils, and scuffing, making it ideal for health, beauty, and industrial products.

- High-Quality Printability: Specially treated surface ensures fast ink drying, sharp details, and vibrant color reproduction up to 4800 x 1200 dpi resolution.

- Value 2-Pack: Includes two individual rolls, maximizing uptime and reducing the frequency of reordering.

Why It Matters: Practical Benefits for Your Business

When running a busy labeling operation, efficiency and durability are critical. Standard paper labels often fail under challenging conditions, leading to smudged graphics and a damaged brand image. Our High Gloss BOPP roll eliminates these concerns:

- Professional Durability: Ensure your product labels remain intact, vibrant, and legible, even when exposed to refrigeration, oils, or frequent handling. This is essential for longevity and customer satisfaction.

- Design Freedom: The non die-cut (continuous) format, combined with the IColor 250's cutter, lets you create any label shape your branding requires, minimizing waste and inventory holding costs associated with specialized pre-cut labels.

- Optimal Compatibility: This media is perfectly matched to the IColor 250's thermal inkjet technology, guaranteeing seamless feeding, rapid printing, and consistent, high-resolution output every time.

Specs & Compatibility

- Material: White Gloss BOPP (Biaxially Oriented Polypropylene)

- Adhesive Type: Permanent, General Purpose

- Format: Continuous Roll (Non Die-Cut)

- Roll Dimensions: 4.75 inches wide x 125 feet long (121 mm x 38.1 meters) per roll

- Package Quantity: 2 rolls (2-Pack)

- Compatibility: Specifically designed for the IColor 250 Inkjet Color Label Printer & Cutter.

Who This Is For

This continuous BOPP media is the perfect solution for businesses that require durable, professional, and variable-shaped labeling.

- Health & Beauty Brands: Ideal for cosmetics, soaps, essential oils, and wellness products that encounter moisture and oils.

- Food & Beverage Producers: Excellent for refrigerated goods, jarred products, and items requiring moisture resistance.

- Small Manufacturing/Industrial: Suitable for labeling parts, containers, and durable goods where resistance to chemicals and scuffing is necessary.

- Custom Label Services: Use the IColor 250 and this roll to offer clients maximum design flexibility and superior label quality.

How to Use

- Loading: Mount one roll onto the IColor 250's media spool, ensuring the media feeds smoothly and is aligned with the print head.

- Design & Print: Use your design software and the IColor 250’s CustomCUT software to create your desired label graphic and corresponding digital cut line.

- Digital Die-Cutting: The continuous feed allows the IColor 250 to first print the label and then automatically cut the custom shape immediately after printing, eliminating the need for costly external cutting dies.

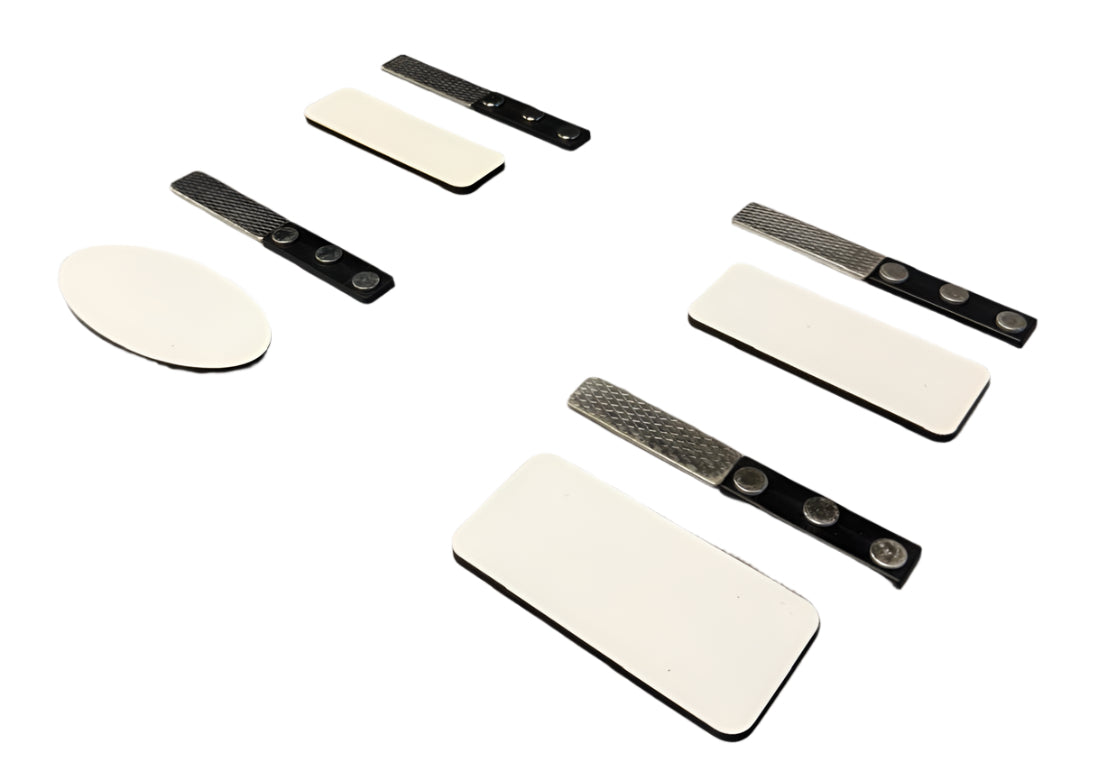

- Application: Peel the finished, die-cut label from the distinctive crosshatch liner and apply it to your product packaging.

| Peel | |

|---|---|

| Equipment | |

| Image | |

| Pressure | |

| Application Temperature | |

| Time |