Each printing technique—Direct-to-Garment (DTG), Direct-to-Film (DTF), and sublimation—offers unique benefits and challenges, ideal for different applications and materials. Here’s a closer look at the essentials of each printing method to help you decide which one fits your project best.

The Basics of DTF, DTG, and Sublimation

Direct-to-Garment (DTG) Printing

How It Works:

DTG printing uses specialized inkjet technology to print designs directly onto fabric. It’s most effective on cotton and cotton-blend garments, as these fibers absorb the water-based DTG inks, producing vibrant colors. For darker fabrics, a pretreatment process is applied to ensure the ink bonds well and maintains clarity.

Why Choose DTG?

- Material Compatibility: Best suited for cotton and cotton-blend fabrics, ensuring exceptional results on natural fibers.

- Color Accuracy: DTG excels at capturing fine details, gradients, and photo-quality prints, making it perfect for intricate designs.

- Maintenance Considerations: Regular upkeep is essential to prevent printhead clogs, especially when using white inks, ensuring consistent quality prints.

Take the Epson® F1070 Hybrid Printer as an example—this powerful DTG machine delivers high-quality, photo-realistic prints on both light and dark garments, making it an ideal choice for businesses aiming to offer top-notch, custom prints on cotton-based fabrics.

Best Applications:

Small custom orders for t-shirts, sweatshirts, or other cotton-based items that require detailed, colorful designs and a soft feel.

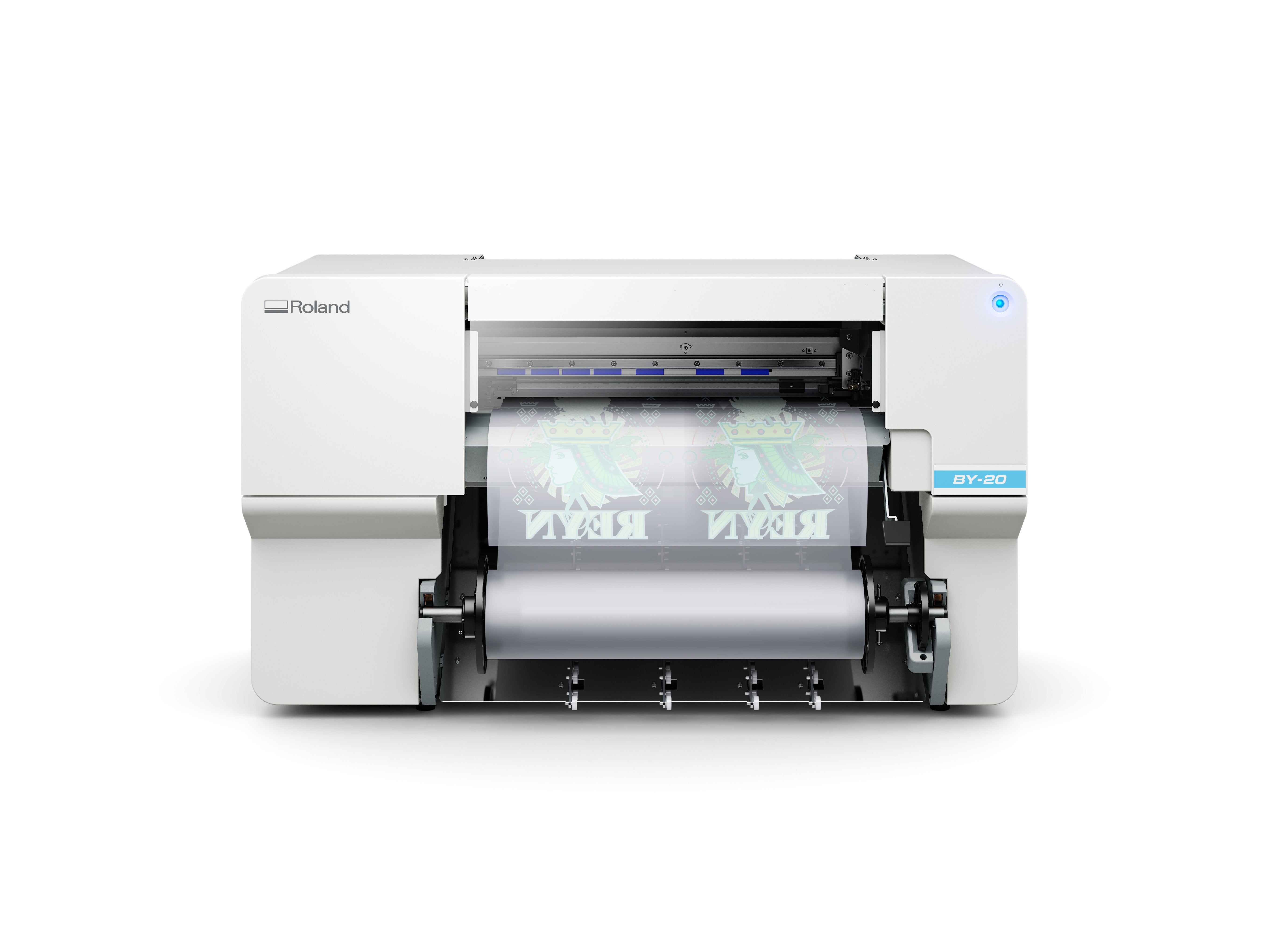

Direct-to-Film (DTF) Printing

How It Works:

DTF printing transfers ink onto a specialized film, which is then coated with a hot-melt adhesive powder. Once the design is ready, it’s heat-pressed onto the fabric, bonding securely with the garment. DTF’s unique approach makes it adaptable to various fabric types without needing pretreatment.

Why DTF Stands Out:

- Versatility: DTF isn’t limited to just fabrics like cotton and polyester. It also works on blends and non-fabric items like bags, giving you endless creative possibilities.

- Durability: DTF prints are incredibly durable, resisting fading, cracking, or peeling even after numerous washes.

- Ease of Use: While the process requires handling the transfer film and adhesive powder, DTF eliminates the need for pretreatment on dark fabrics, making it a simpler and more efficient choice compared to other methods.

DTF is ideal for producing long-lasting, high-quality prints across a variety of materials—from apparel to accessories, making it a versatile solution for all your printing needs.

The OtterPro DTF All-in-One System is a perfect example of DTF technology in action. This integrated system streamlines the process, making it easier to achieve exceptional prints on both fabrics and non-fabric materials. It's a solid choice for anyone looking to elevate their custom print business.

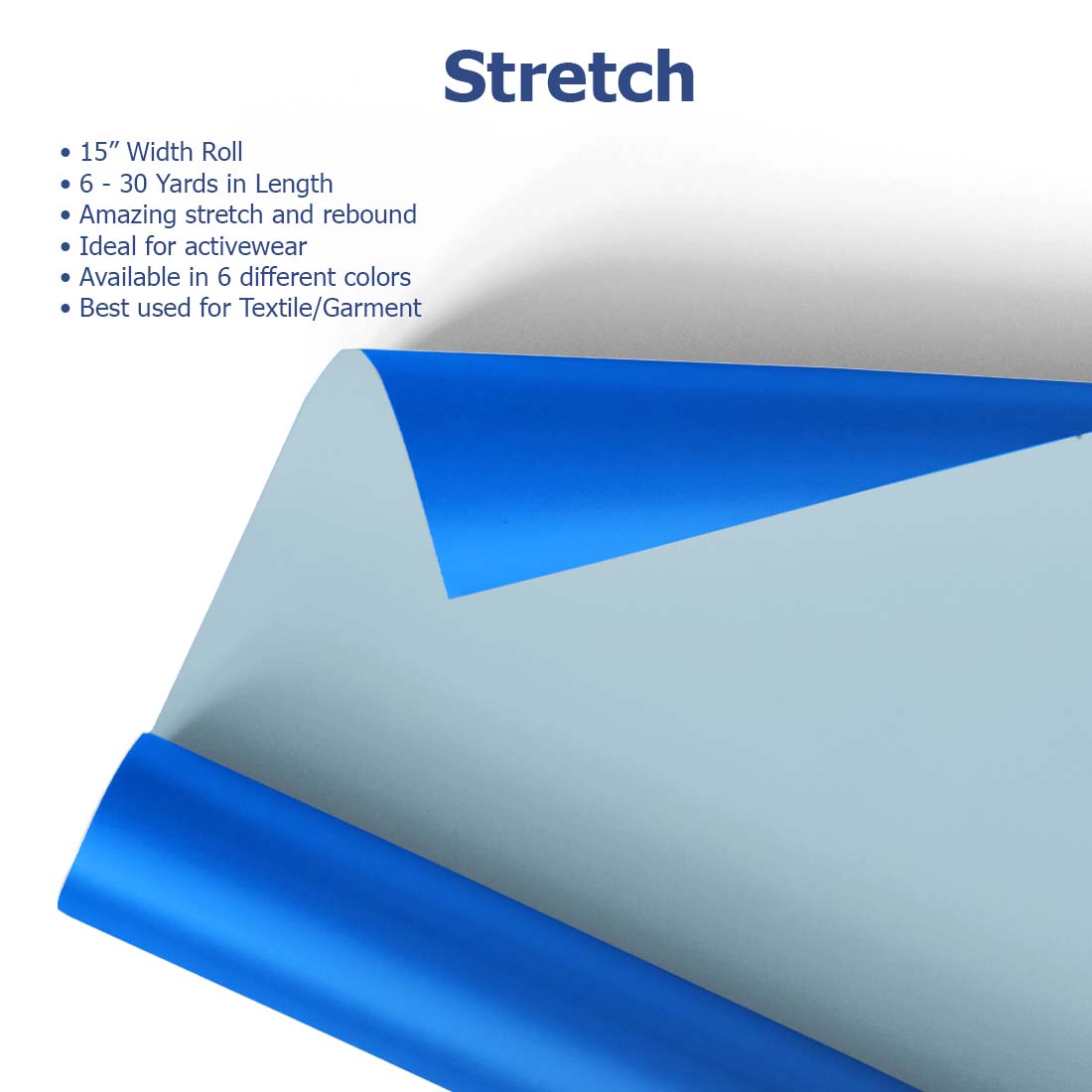

Sublimation Printing

How It Works:

Sublimation printing turns dye-based ink into gas using heat and pressure, embedding the design directly into the fibers or coating of the material. Because the ink bonds with polyester or a polymer coating, sublimation only works on materials that have a high polyester content or items coated with a polymer layer, like sublimation-friendly mugs or signage.

The Epson® SureColor F570 is a high-performance sublimation printer, perfect for producing vibrant, durable prints on polyester and polymer-coated items, allowing you to effortlessly bring your designs to life with exceptional clarity and precision.

Key Features:

- Vibrant, Long-Lasting Colors: Sublimation printing delivers stunning, high-impact colors that won’t fade. The ink bonds permanently with the fabric, becoming an integral part of it.

- Perfect for Polyester & Coated Items: This method works best on polyester or polymer-coated materials, so it’s not ideal for cotton.

- Best on Light-Colored Backgrounds: Sublimation shines on white or light-colored fabrics because it doesn’t print in white—ensuring your designs pop on lighter surfaces.

Best Applications:

Ideal for polyester apparel, home décor items, and hard goods (like mugs) where a smooth, vibrant print that won’t crack or peel is essential.

What’s Your Choice?

If your projects involve polyester-based items or hard-surface products like mugs, sublimation offers unparalleled durability and color vibrancy. For cotton garments and fabrics that demand fine detail, DTG will be your go-to for smooth gradients and color options, including white.

Important Factors in Choosing the Right Printing Methods

Each method offers its advantages:

- Material Compatibility: Sublimation for polyester, DTG for cotton, and DTF for versatile applications.

- Design Complexity: DTG captures detail beautifully, while sublimation provides a bold, vibrant finish.

- Durability & Feel: Sublimation and DTF offer durable results that resist fading and cracking, while DTG shines in vibrant designs with a soft, flexible feel.

Key Differences at a Glance

| Feature | DTG | DTF | Sublimation |

|---|---|---|---|

| Material Compatibility | Cotton, cotton blends | Broad range (cotton, poly, blends) | Polyester or polymer-coated items |

| Color & Detail | High detail, vibrant on cotton | Bright colors, versatile on fabrics | Exceptional vibrancy, fade-proof |

| Durability | Good, requires maintenance | Highly durable, fade-resistant | Permanent, resistant to peeling/cracking |

| Feel of Print | Soft, fabric-like | Slightly textured | Smooth, embedded |

| Use Case Suitability | Apparel, especially cotton items | Versatile – apparel, bags, more | Polyester items, hard goods |

Learn More About Printing with All Print Heads

For top-quality DTG, DTF, and sublimation printing equipment and inks, visit the Joto Imaging Supplies Product Page. We offer a wide range of sublimation printers, inks, heat presses, and other essential tools tailored to meet your custom printing needs.