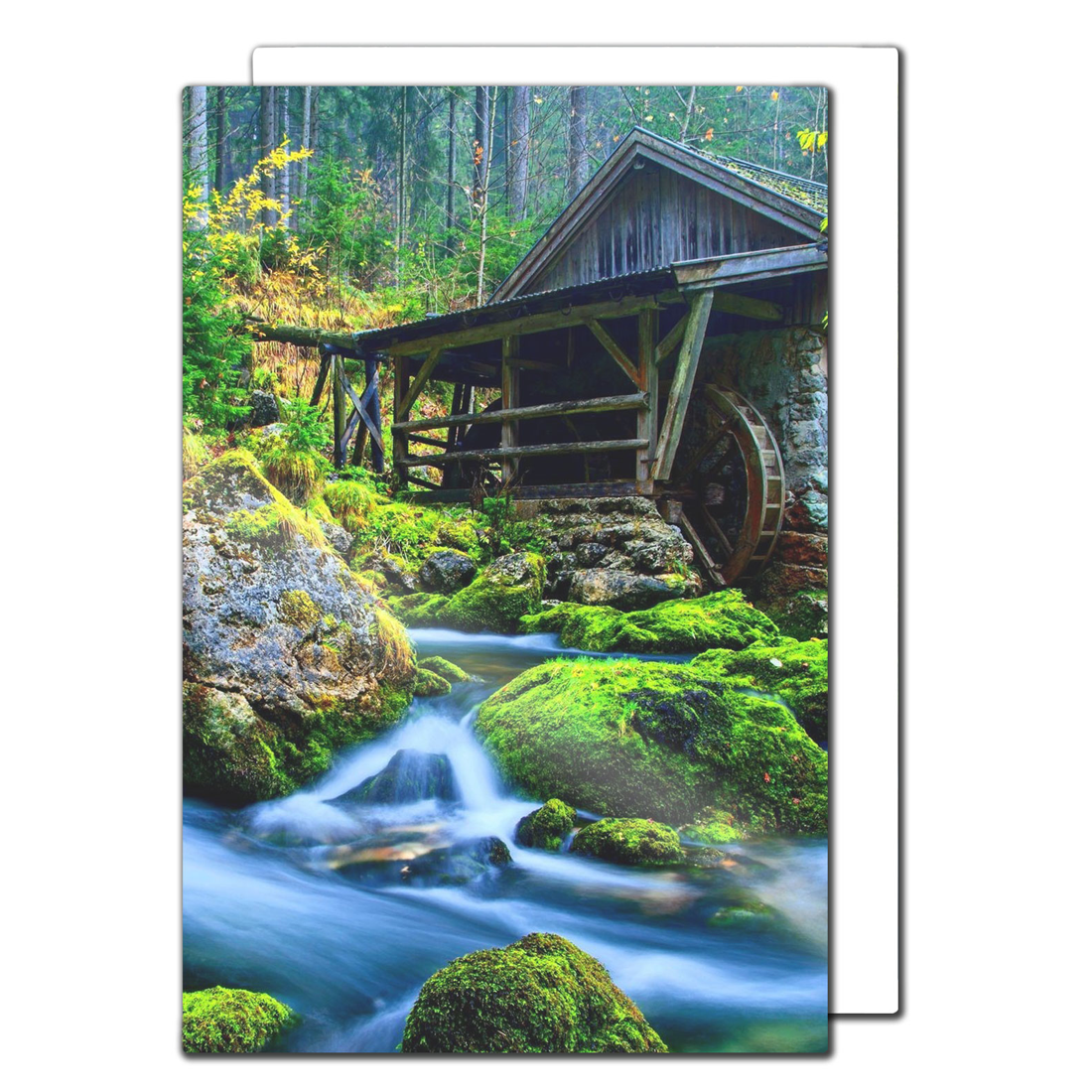

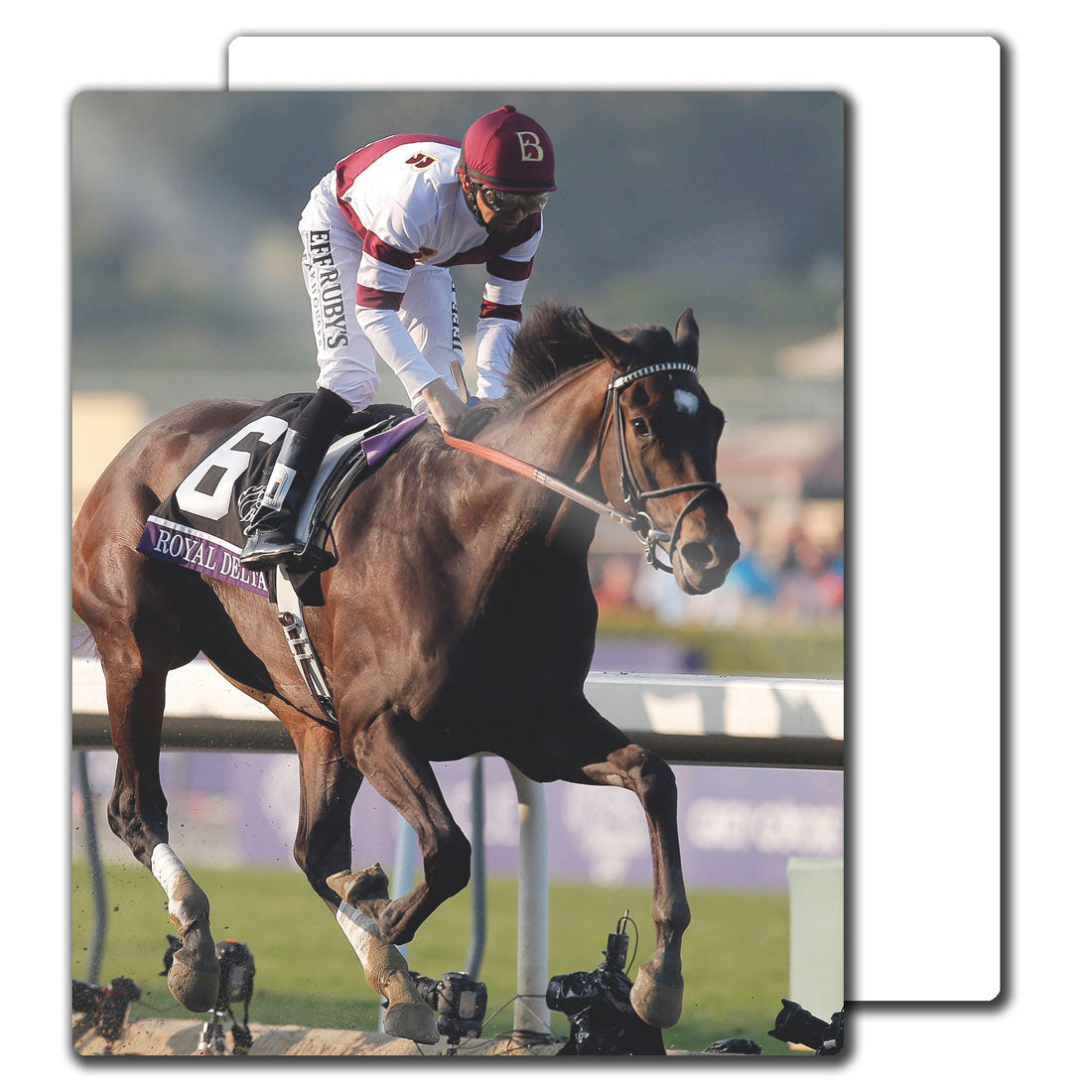

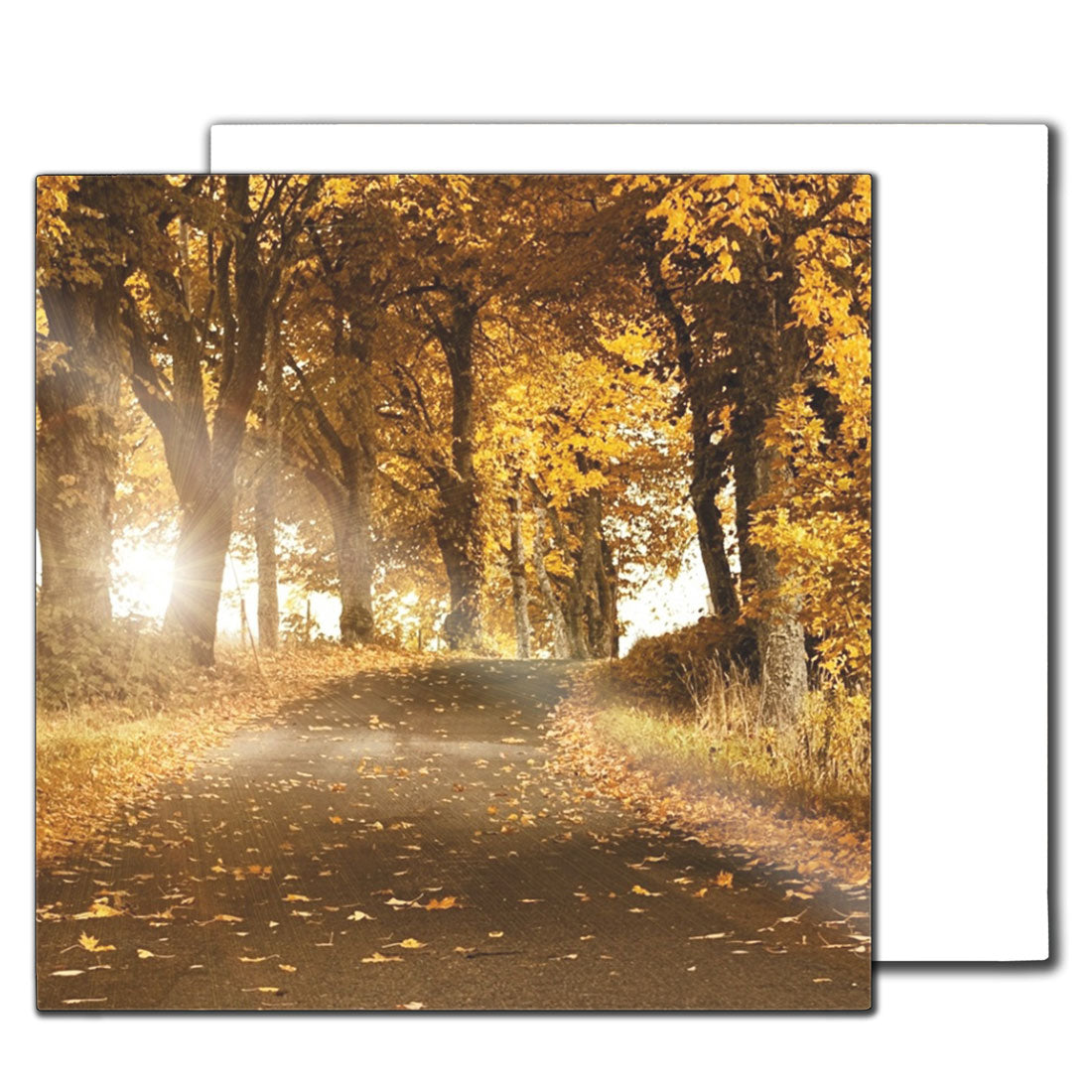

Sublimation Acrylic sheets are made of special material suitable for heat transfer printing. Their surfaces are high gloss white, and the printing effect of the picture is very vivid. The printed Acrylic can be molded into an arc shape using a stainless steel molding tool so it can be placed directly on the table.

- Images have Vibrant & Vivid Colors

- Made of High-Quality Acrylic

- Fade and Scratch Resistant

- High Profits, High Margins

- Panoramic Curved Surface

- Designed for Sublimation

- Attractive Glossy Finish

| Brand | Pearl Coating™ |

|---|---|

| Compatible Technology | Sublimation |

| Dye Blocking | No |

| Experience Pack Text | Case |

| FCC Attribute | Yes |

| Finish | Gloss |

| Ink Configuration | CMY&HDK |

| Metal | Face Up |

| Self-Weeding | No |

| SIP Attribute | Yes |

| Thickness | 0.125" |

| Unit Sell | case |

| Peel | Immediate |

|---|---|

| Equipment | |

| Image | |

| Pressure | Light - Medium |

| Application Temperature | 356°F(180°C) |

| Time | 60 seconds |

| Pressing Instructions | Press the metal at 356F for 60 seconds. Place printed sublimation sheet with image face up on top of paper sheets. Place acrylic on top with white glossy sublimatable side face up. Cover with a sheet of polyester fabric or parchment paper. After pressing, take off the polyester fabric or parchment, then immediately place the acrylic onto the mold while hot. Let it cool for 2-5 mins, then take the acrylic off the mold when it is cold. Handling the acrylic while hot will increase the chance of the acrylic being damaged. For detailed instructions, please download our instructions sheet. |

| Heat Press Size | |

| Imaging Instructions |