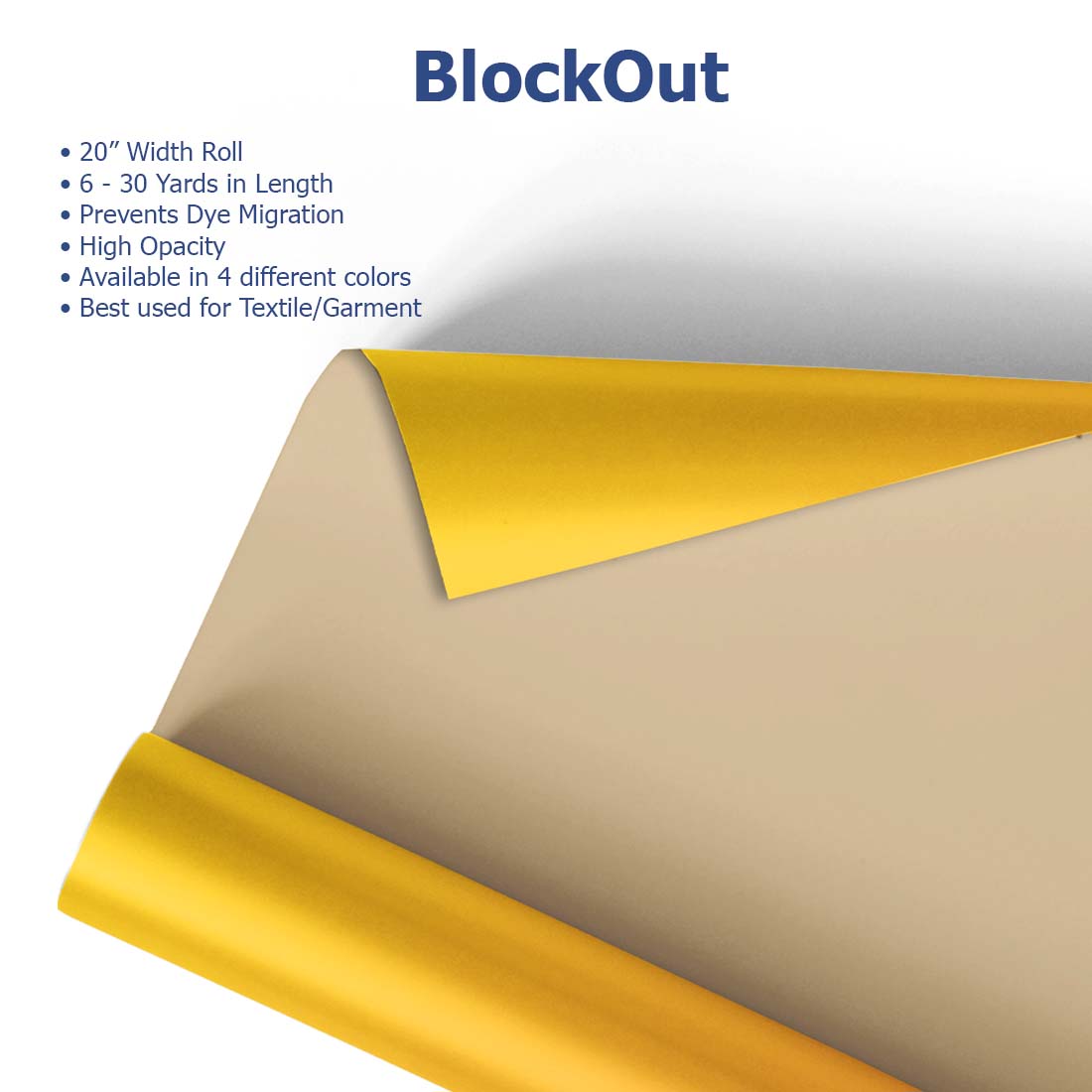

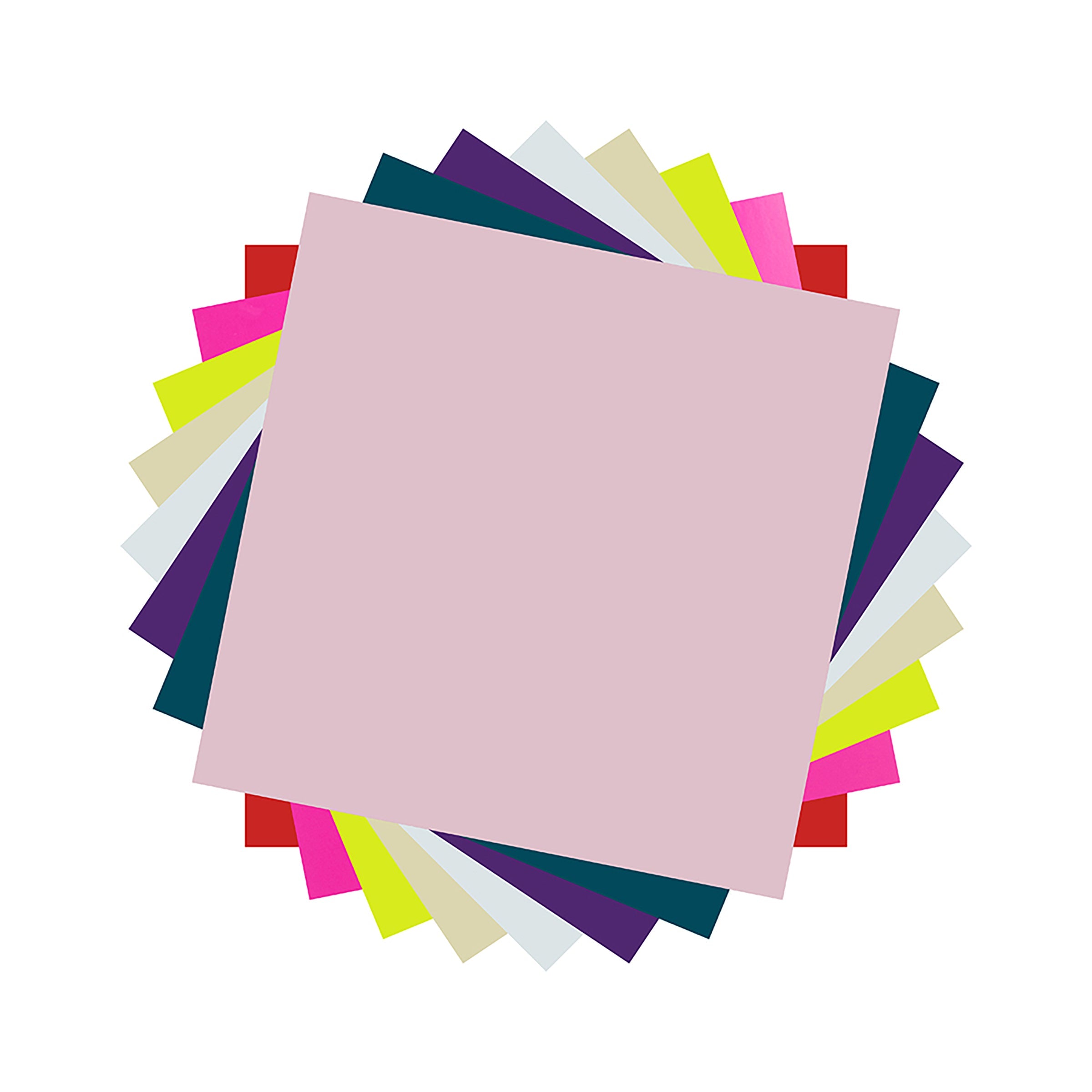

Discover the versatility of heat transfer paper for effortlessly customizing T-shirts, hats, bags and fabrics and substrates. Whether you're aiming to decorate personalized gifts or fashion unique apparel pieces, our collection of heat transfer papers provide a smooth and professional printing experience.

Heat Transfer Papers Collections

- 1

- 2

Heat Transfer Papers – Vibrant, Durable, and Easy to Use

Achieve professional-quality prints every time with our premium Heat Transfer Papers. Perfect for creating custom apparel, promotional items, and personalized gifts, these papers are specially engineered for sharp, vivid transfers that last.

Why Choose Our Transfer Papers:

- Brilliant Color Reproduction – Produces bold, fade-resistant designs with crisp detail.

- Works on Light & Dark Fabrics – Versatile options for cotton, polyester, and blended materials.

- Easy Application – Designed for smooth transfers and simple peeling using a heat press or home iron.

- Professional-Grade Durability – Resists cracking and fading even after repeated washes.

Whether you’re a hobbyist or running a professional print shop, our Heat Papers provide everything you need to create stunning, long-lasting designs. Shop now and bring your custom creations to life with vibrant, professional-quality transfers!

Heat Transfer Paper

How to Use Heat Transfer Paper

Types of Heat Transfer Paper

Can I use heat transfer paper on any fabric?

Do I need to mirror my design before printing on heat transfer paper?

How long should I heat press my design onto the fabric?

Can I use an iron instead of a heat press when using heat transfer paper?