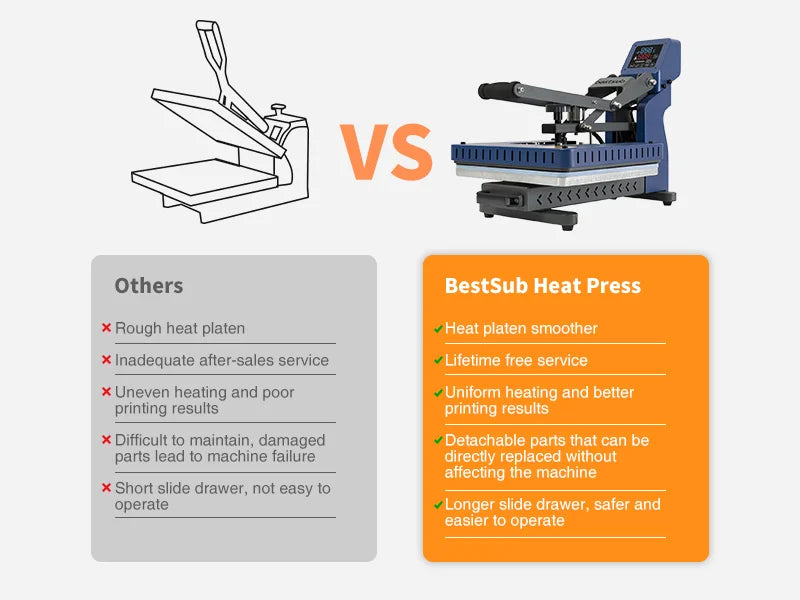

Clam shell heat presses - efficient production

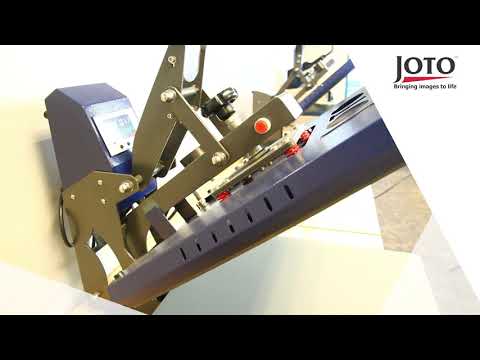

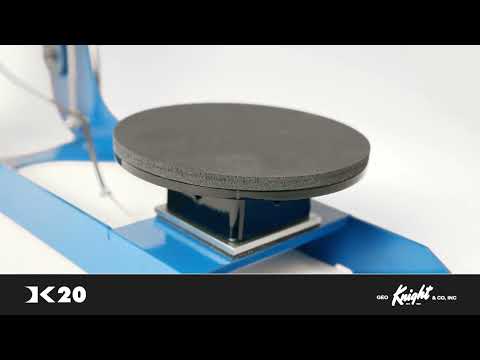

Clam shell heat presses are a favorite among shops that value speed and simplicity. Their top platen opens vertically, making them compact and ideal for smaller workspaces without sacrificing performance.

With even heat distribution and adjustable pressure, they deliver crisp, durable transfers on garments, bags, and flat substrates. These presses heat quickly and maintain stable temperatures, helping reduce downtime and improve turnaround.

Their straightforward design makes them beginner friendly while still powerful enough for professional use. Perfect for schools, small businesses, and growing studios, clam shell presses are a cost-effective way to enter or expand heat transfer production.

Durable construction ensures long service life, while ergonomic operation reduces operator strain during busy shifts. Supported by Joto’s expert guidance and stocked locally across North America, this collection keeps your workflow smooth, dependable, and ready for growth.