Shuttle presses for nonstop productivity

Keep projects moving with shuttle presses, engineered to maximize efficiency by letting you prep one platen while the other is in action.

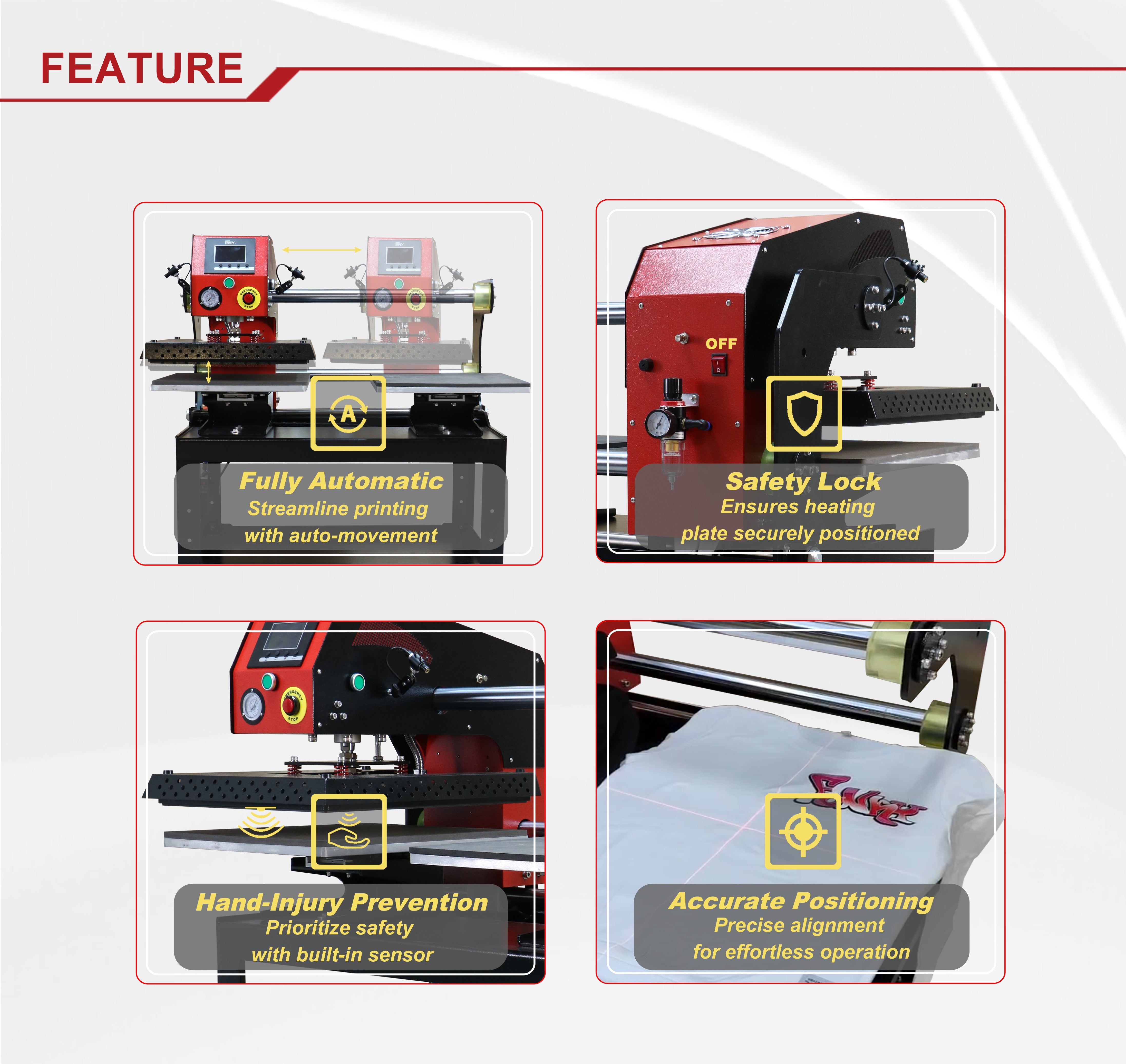

Shuttle presses are the answer for shops that want speed without losing accuracy. With dual sliding platens, operators can load and unload materials on one side while the opposite side applies perfect heat and pressure. This continuous cycle reduces downtime and makes it possible to handle larger orders in less time. Built for heavy-duty use, shuttle presses maintain consistent temperatures and even pressure across wide surfaces, ensuring flawless transfers on garments, panels, and specialty substrates. Their design also minimizes operator strain, making long production runs more comfortable and efficient. Ideal for businesses ready to scale, they combine durability with smart ergonomics to boost throughput. Stocked locally across North America and backed by Joto’s technical expertise, this collection helps transform demanding workloads into smooth, reliable output that keeps customers coming back.