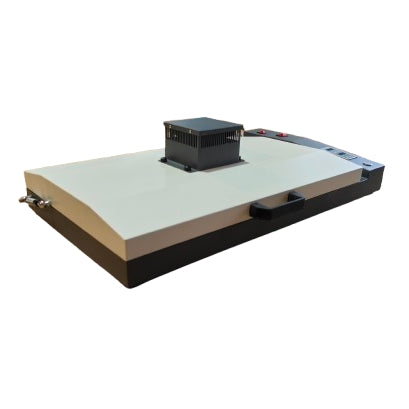

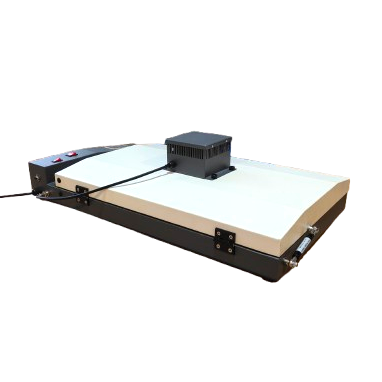

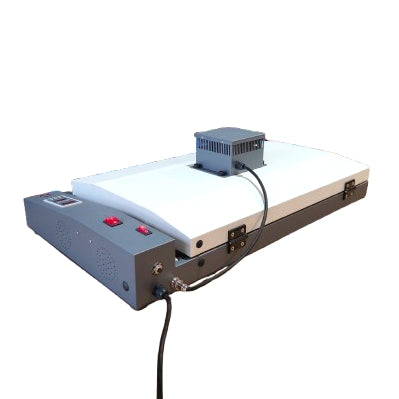

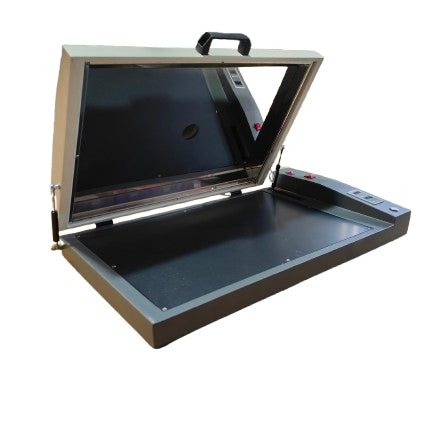

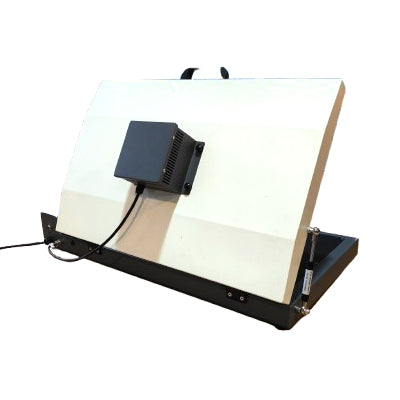

Mica Sheet DTF Oven

The Mica Sheet DTF Oven is a professional curing unit designed specifically for direct-to-film (DTF) printing workflows. Equipped with a mica heating element, this oven delivers fast, stable, and uniform heating, ensuring powder adhesives are properly melted and transfers are cured for maximum durability.

Built for efficiency and reliability, the oven includes adjustable temperature and timing controls, making it easy to achieve consistent curing results across different film sizes and designs. Compact and durable, it is an essential tool for both small shops and high-volume production environments requiring dependable transfer curing.

Key Features:

- Mica heating element for rapid, uniform heat distribution

- Adjustable temperature and timer controls for precision curing

- Durable insulated chamber for stable heat retention

- Compact footprint ideal for desktop or shop integration

- Energy-efficient performance with reliable consistency

- Designed to improve transfer adhesion and wash resistance

Personalization Options:

This oven is compatible with all DTF transfer films and works across a wide range of garment types including cotton, polyester, blends, and specialty fabrics. By ensuring even curing, it allows businesses to deliver custom t-shirts, hoodies, uniforms, and promotional products with durable and professional-quality results.

Printing Compatibility:

- All DTF printers using PET transfer films

- Works with standard hot melt powders

Sublimation Instructions – Mug Press:

- Not applicable – this product is a curing oven, not for sublimation

Sublimation Instructions – Convection Oven:

- Not applicable – this product is a curing oven, not for sublimation

Product Specifications:

- Heating Element: Mica sheet for fast and even heating

- Temperature Range: Adjustable per production requirements

- Timer: Adjustable curing timer for consistent results

- Chamber: Insulated design to retain heat and improve efficiency

- Dimensions: Compact footprint suitable for small to mid-size shops

- Power Supply: As specified in user guide

- Application: PET transfer films coated with DTF hot melt powders

Important Usage Notes:

- Preheat the oven to target temperature before inserting films

- Do not exceed recommended curing time to avoid film damage

- Ensure films are evenly placed inside the chamber for uniform results

- Use protective gloves when handling hot films after curing

- Keep the oven clean and free of powder residue for consistent performance

Perfect For:

- DTF print shops requiring consistent curing results

- Small businesses seeking an affordable, compact curing unit

- High-volume decorators needing reliable powder adhesion

- Producers of custom apparel, uniforms, and promotional goods

Handling & Storage Recommendations:

- Operate the oven in a well-ventilated environment

- Turn off and unplug the unit when not in use

- Store in a clean, dry place to protect electronic components

- Follow maintenance tips provided in the operation guide for long-term reliability

| Controller | Digital Time & Temp. Control |

|---|---|

| Max Temperature | 225℃ |

| Power | 1260W (KX-24) |

| Printer Paper Sizes | 40x60cm |

| Temperature Range | 150°C – 165°C (302°F – 329°F) |

| Time Range | 0-999 sec. |

| Voltage | 110V/ 220V |

| Peel | |

|---|---|

| Equipment | |

| Image | |

| Pressure | |

| Application Temperature | |

| Time |