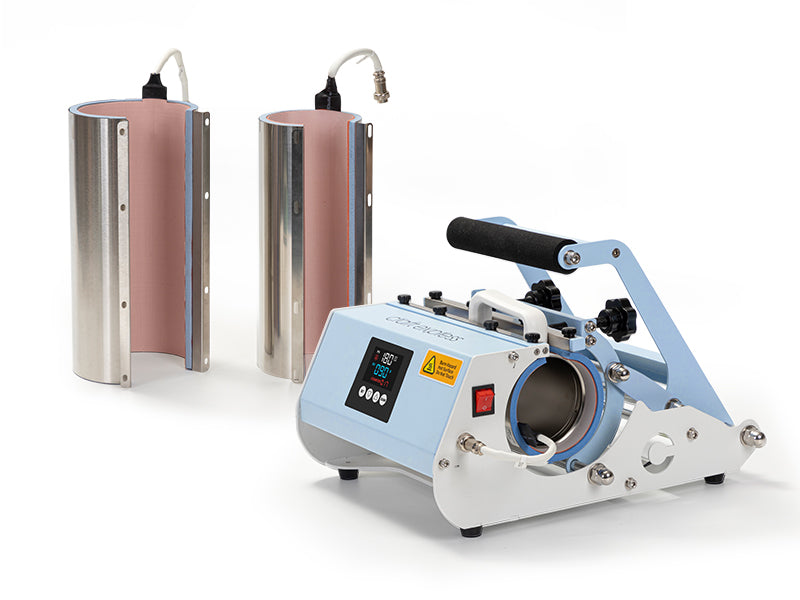

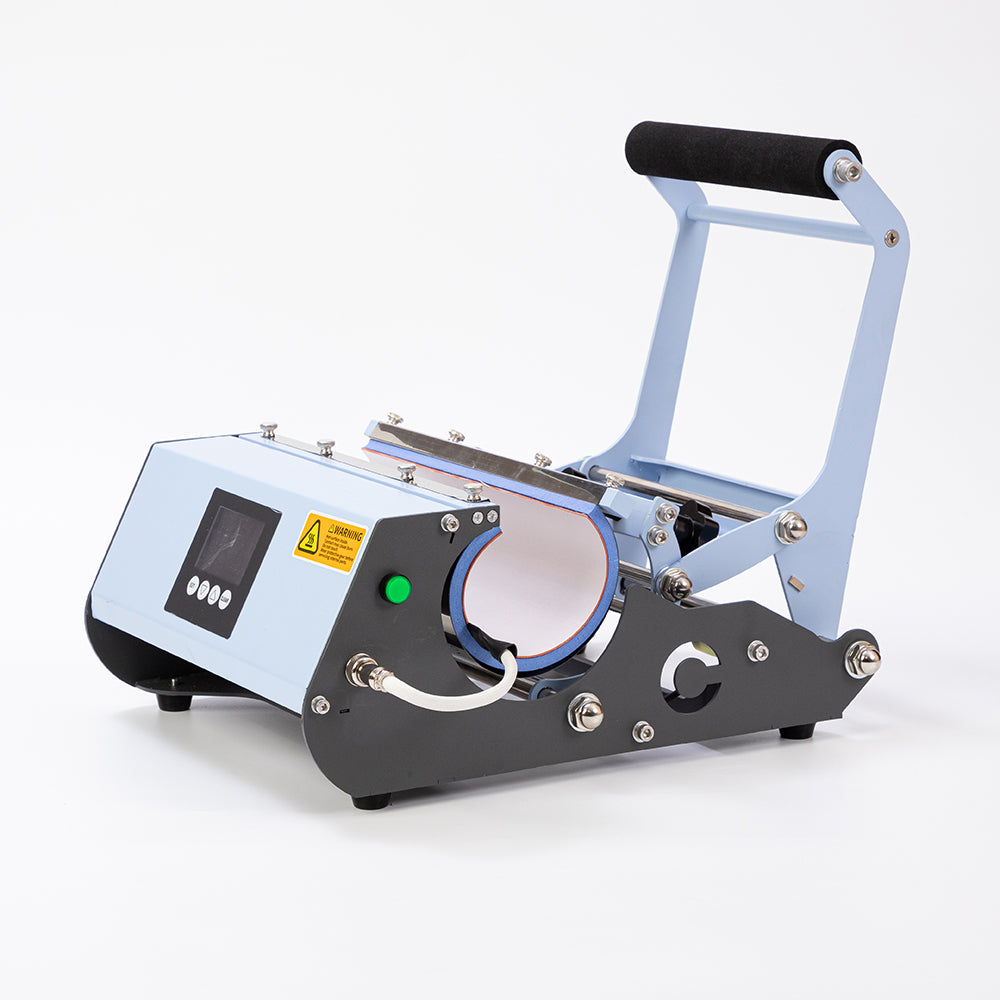

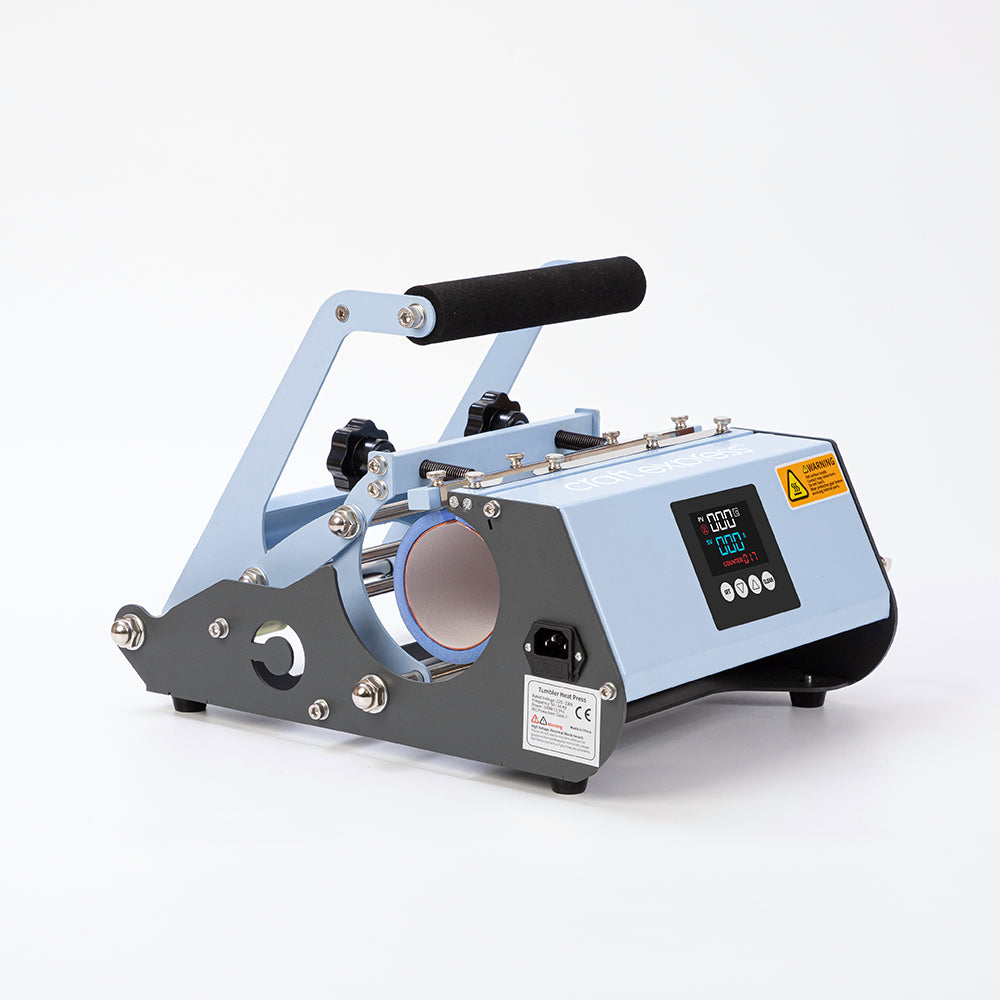

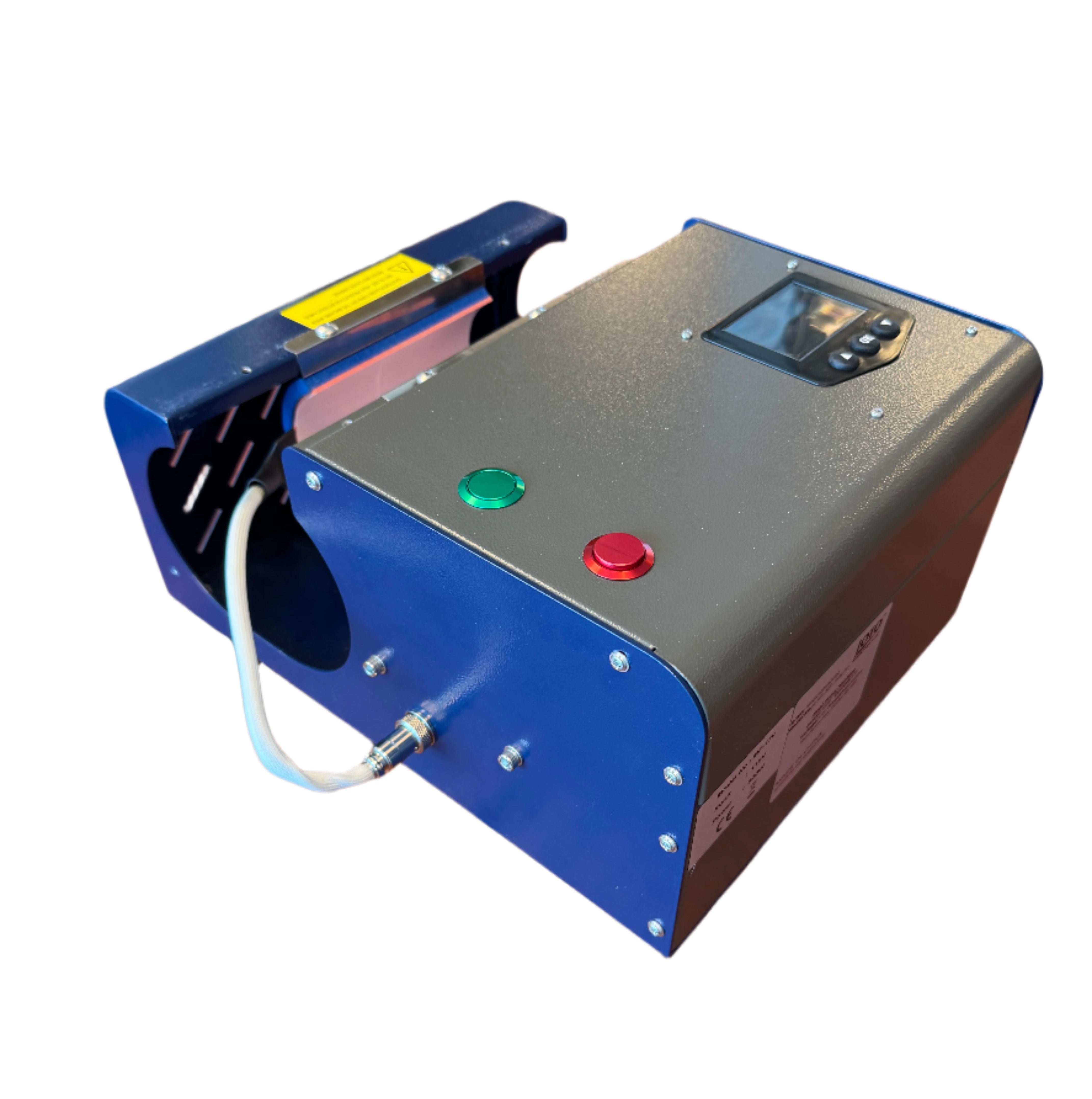

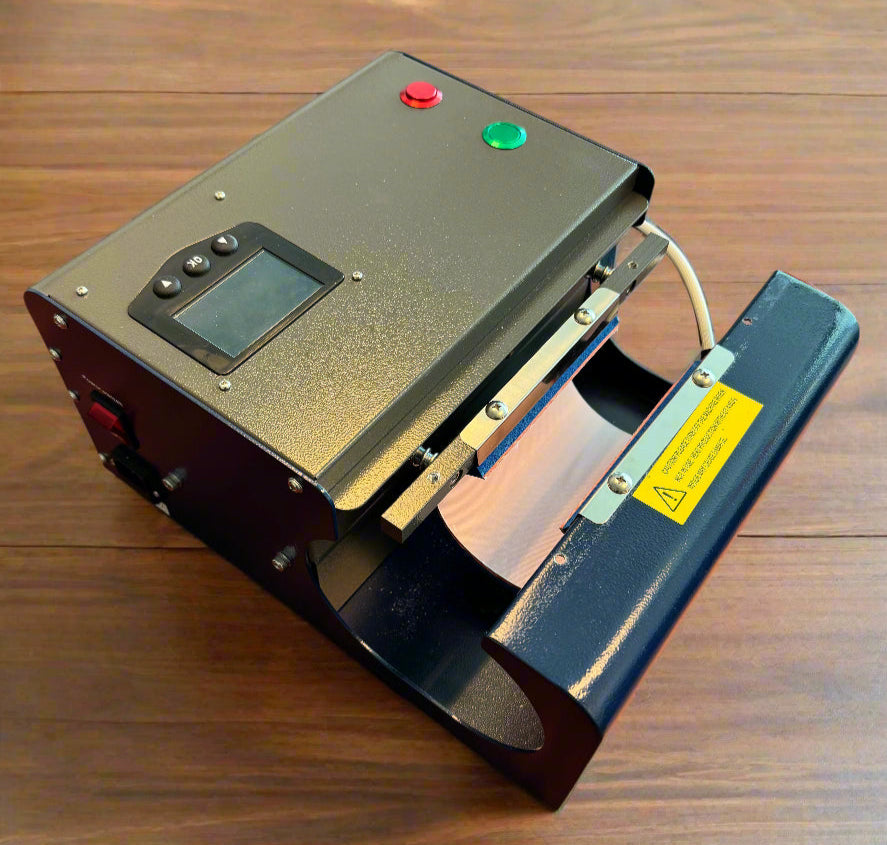

Mug presses for perfect personalization

Create custom mugs with vibrant designs using mug presses that combine steady heat, reliable pressure, and easy operation.

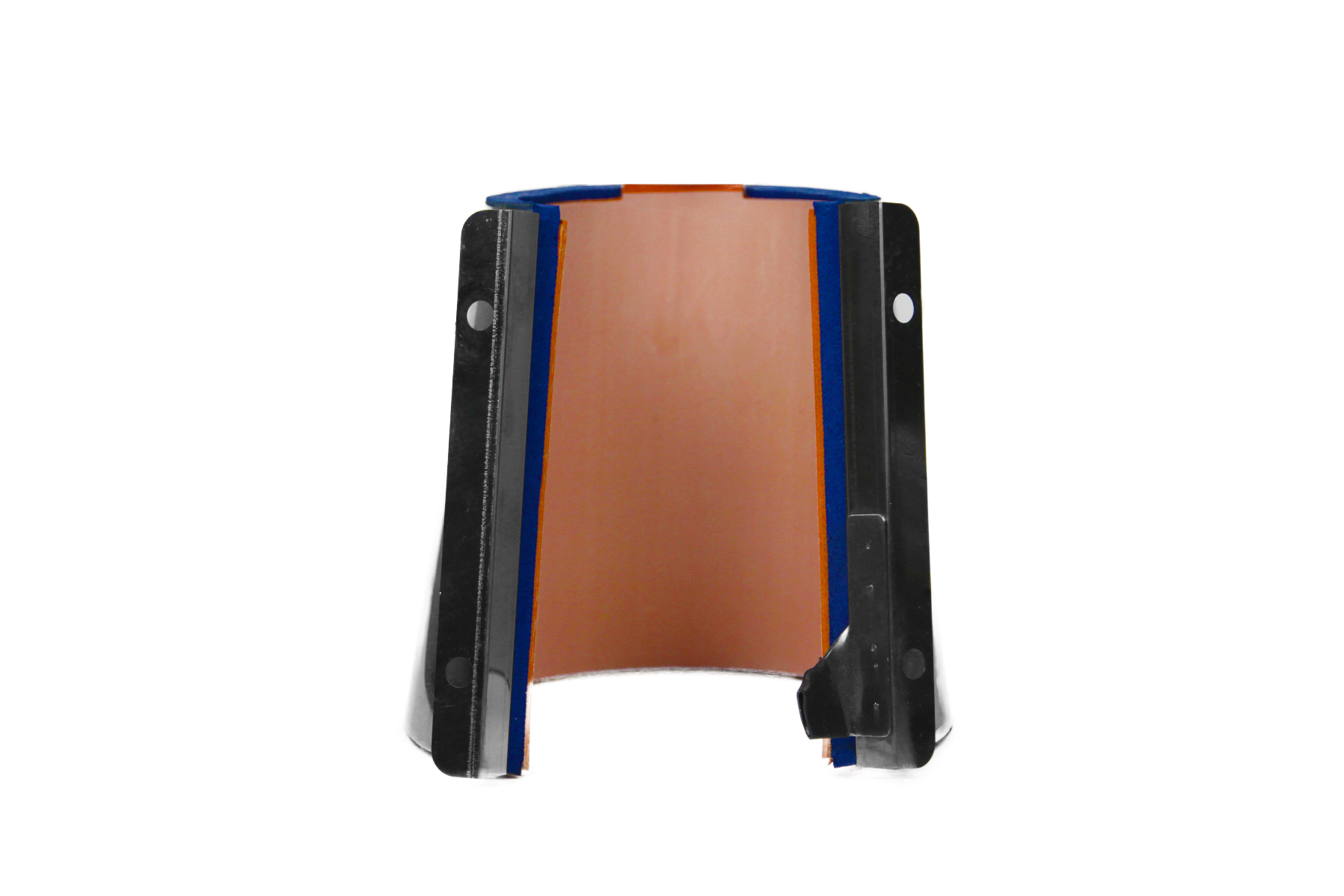

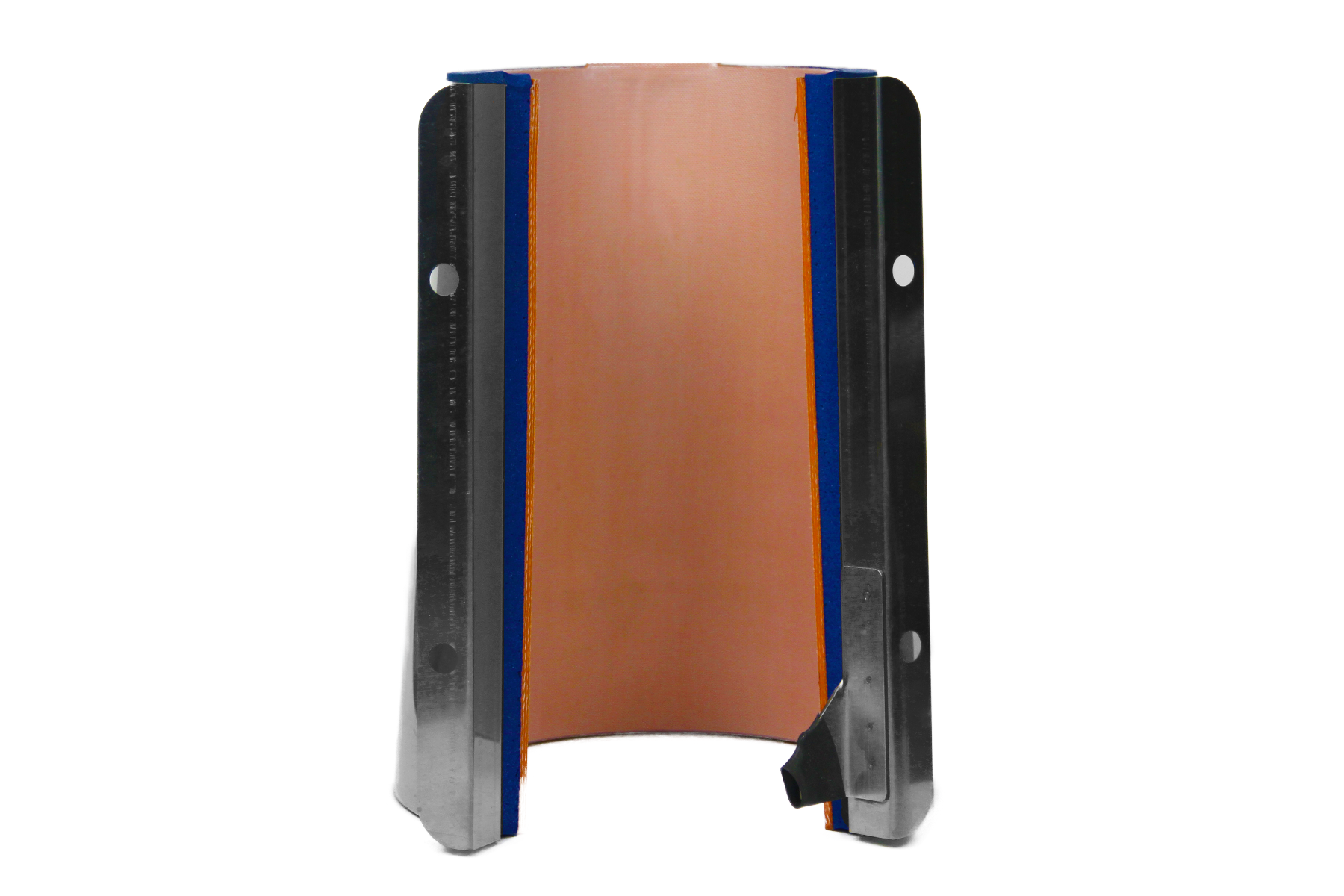

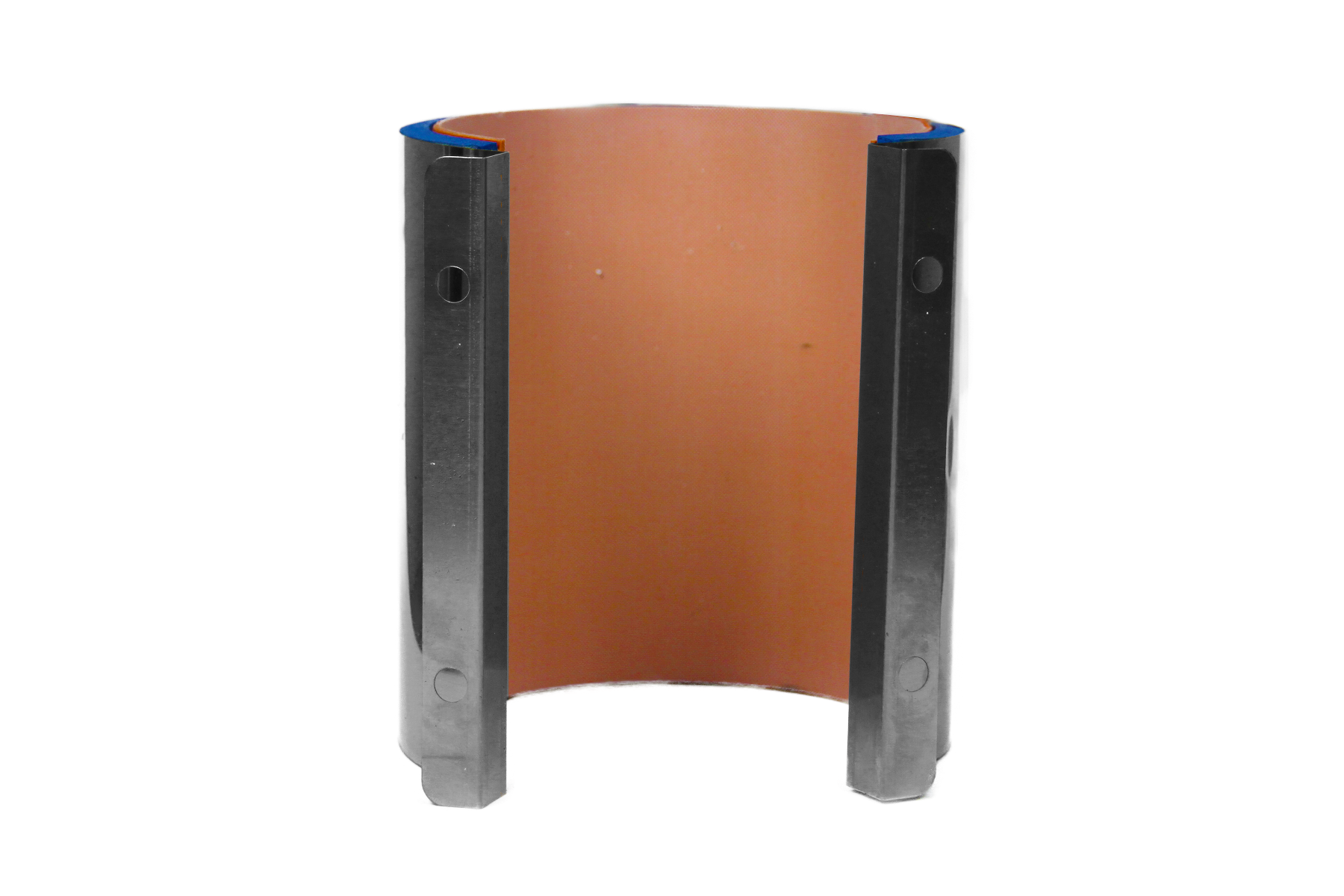

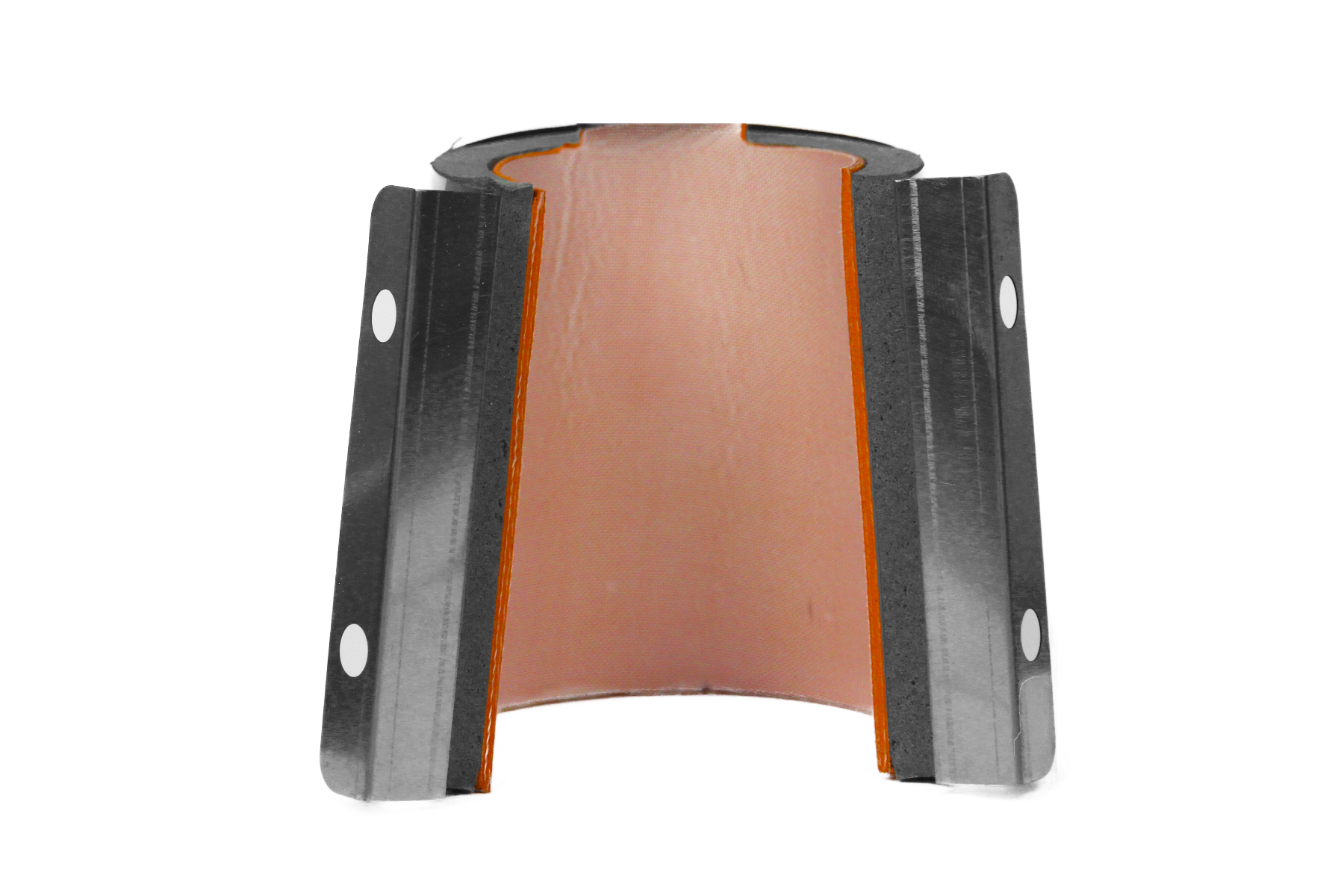

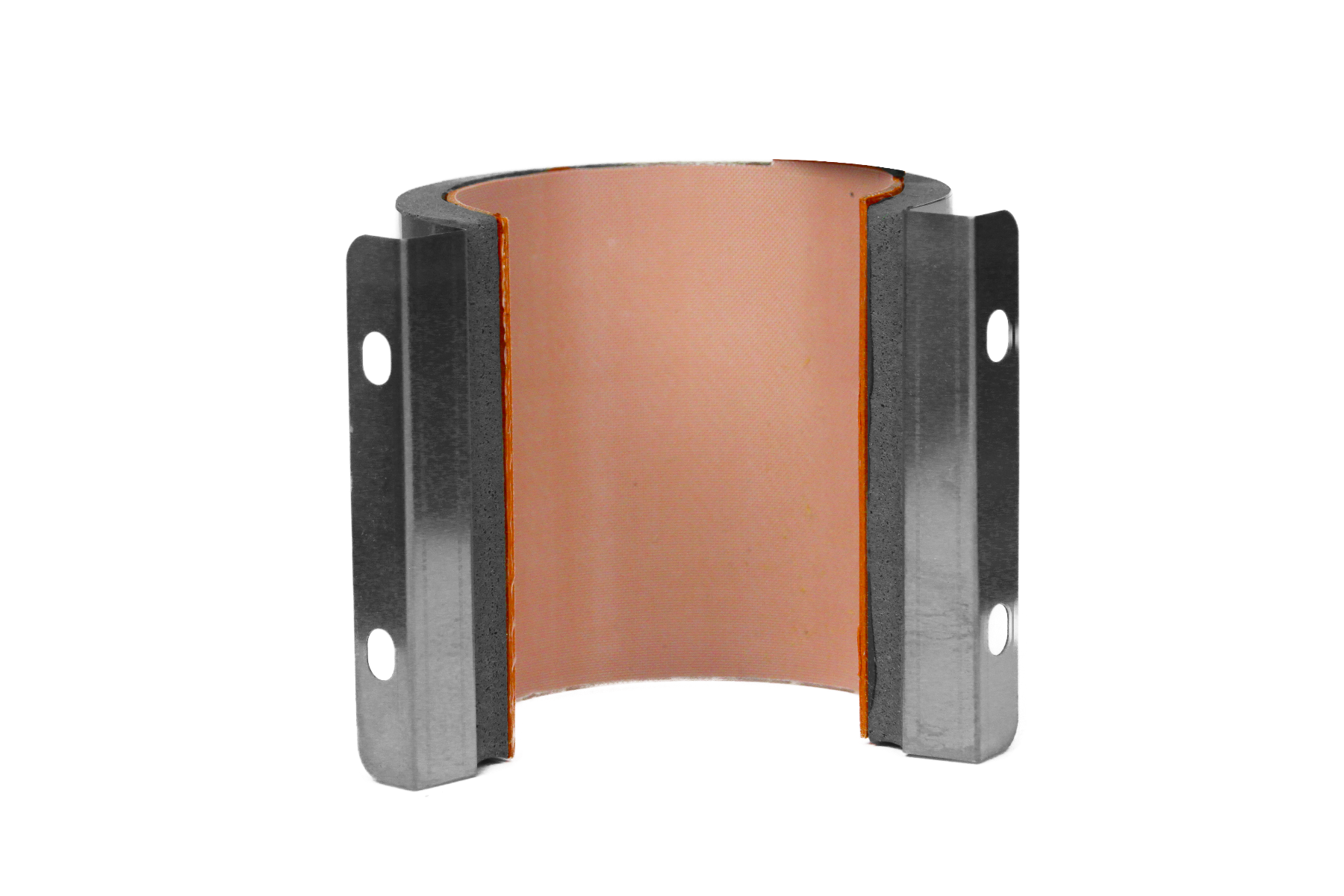

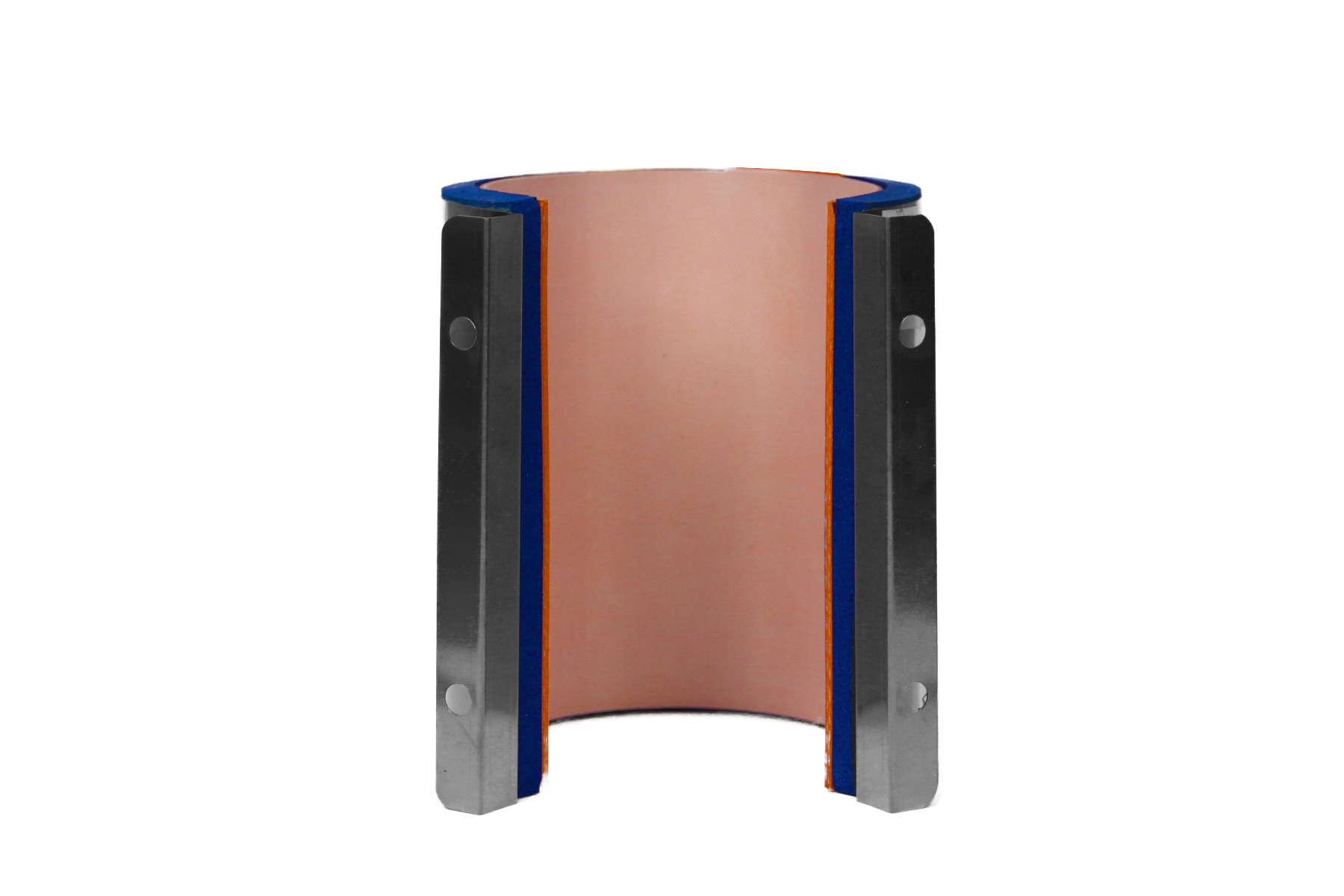

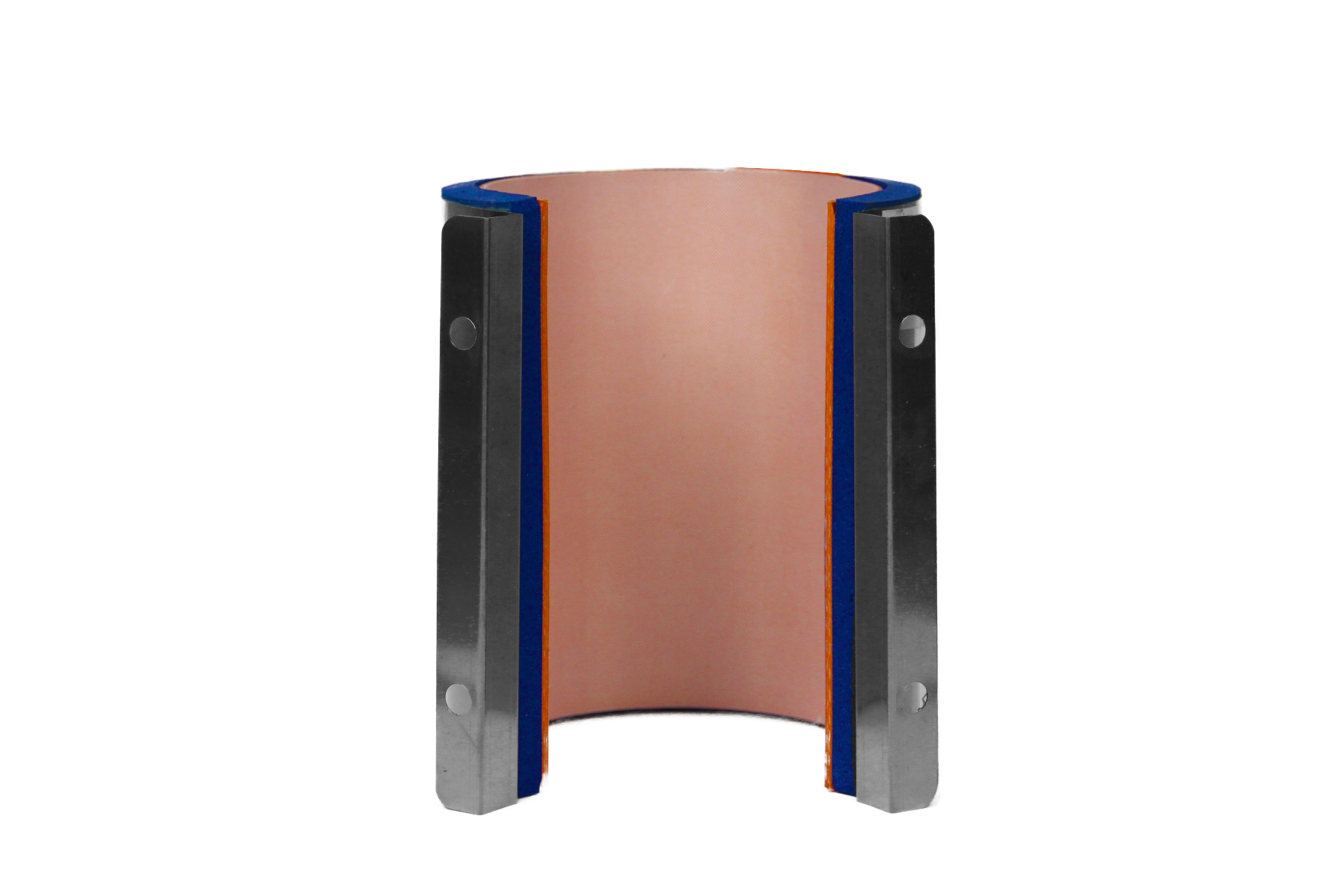

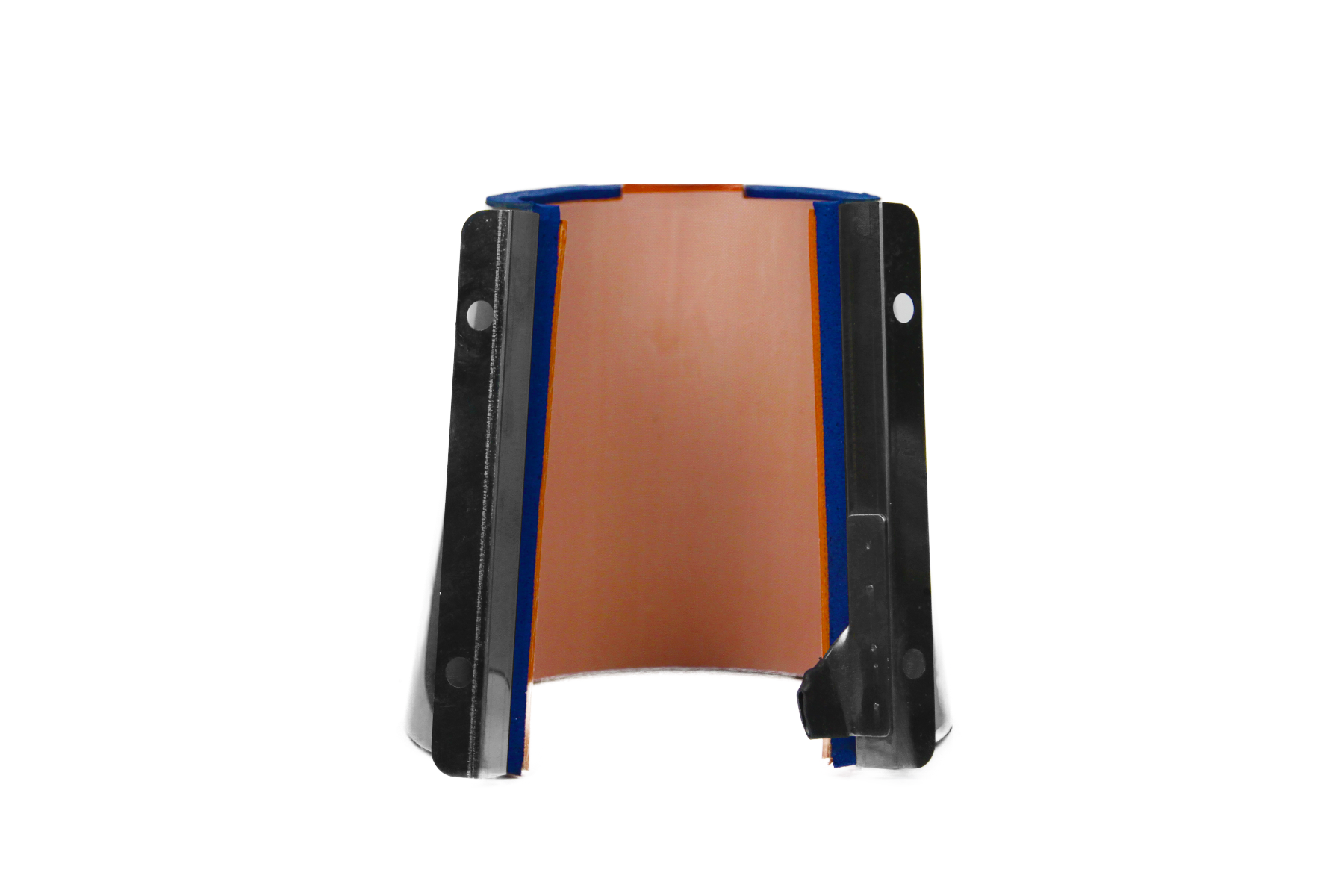

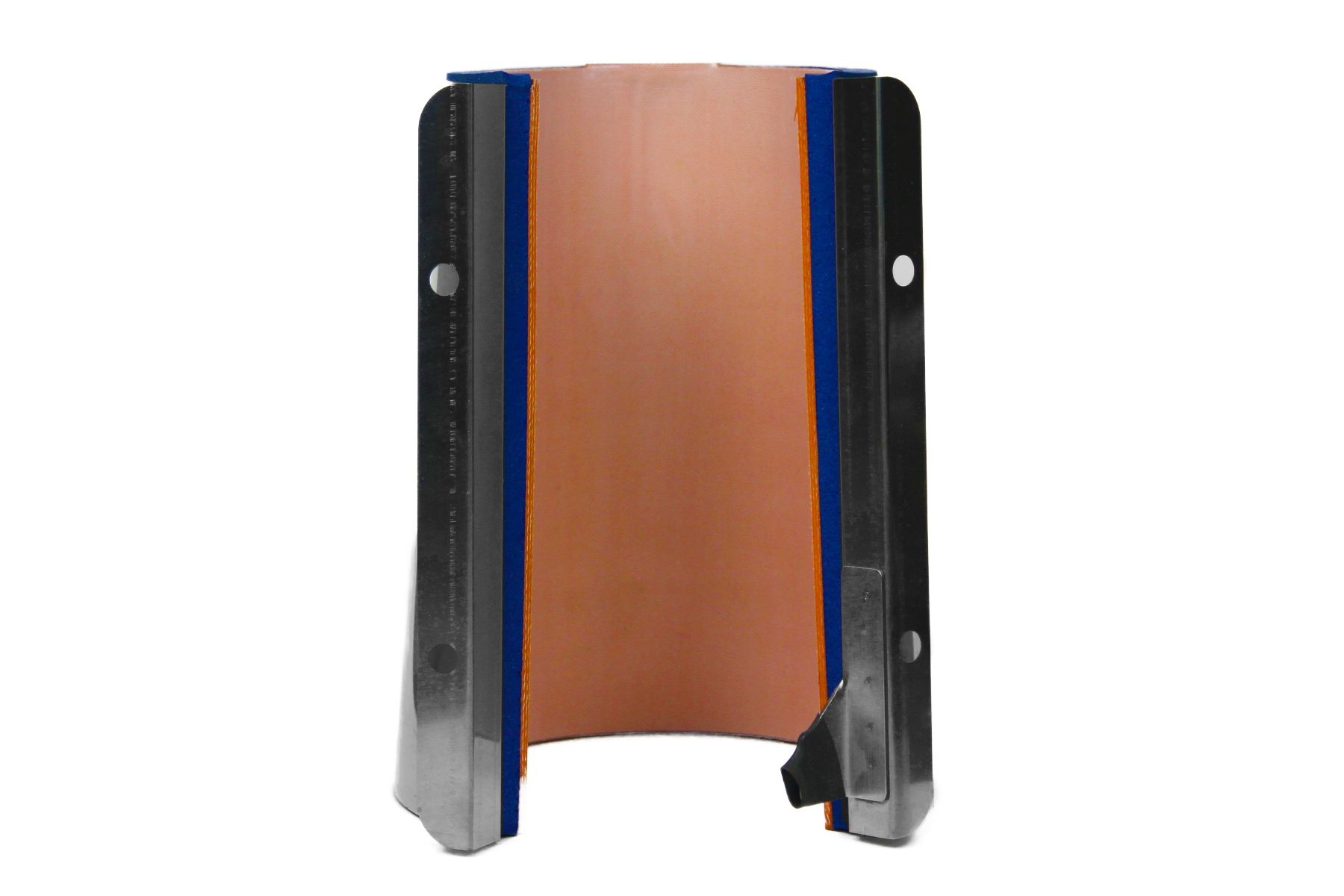

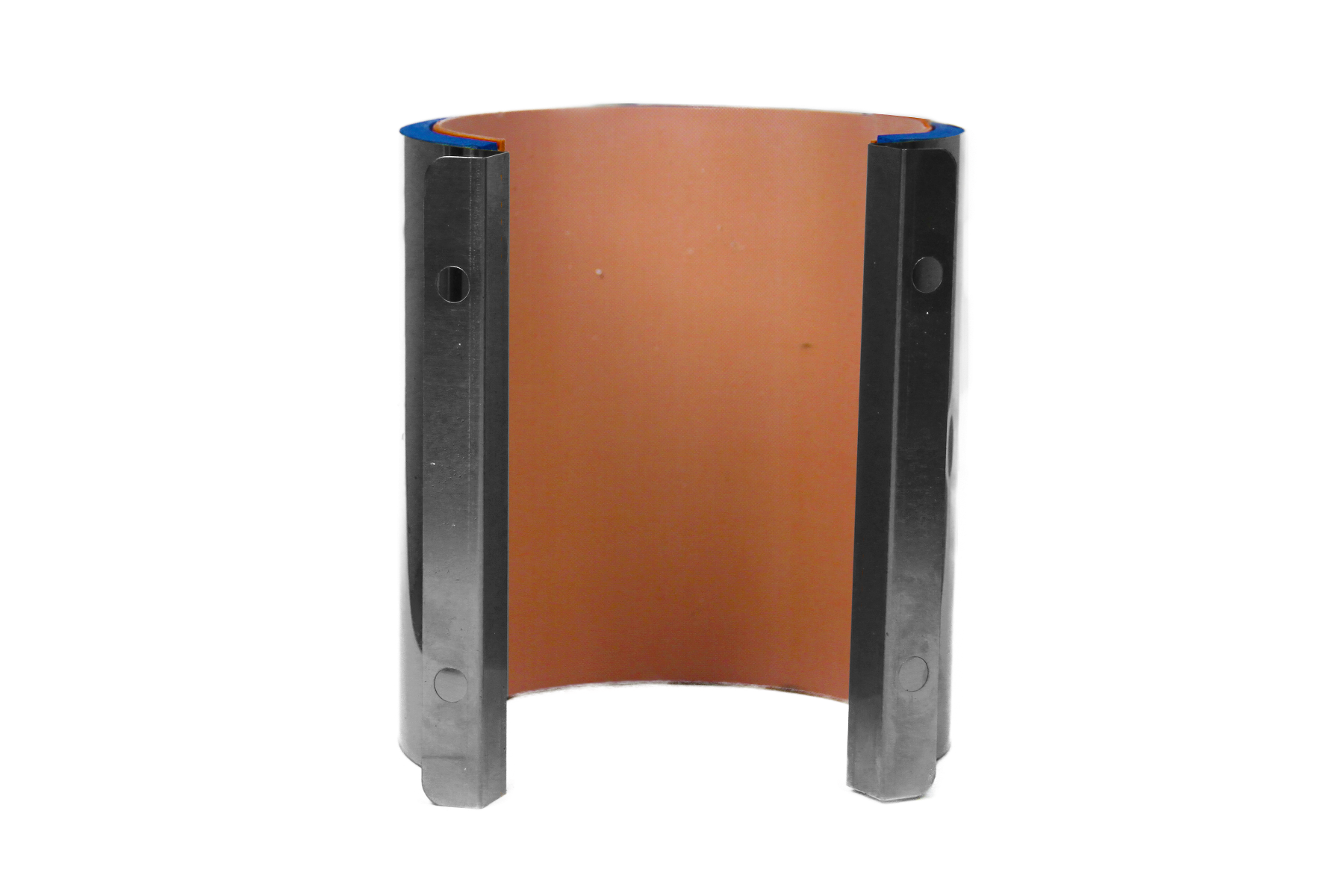

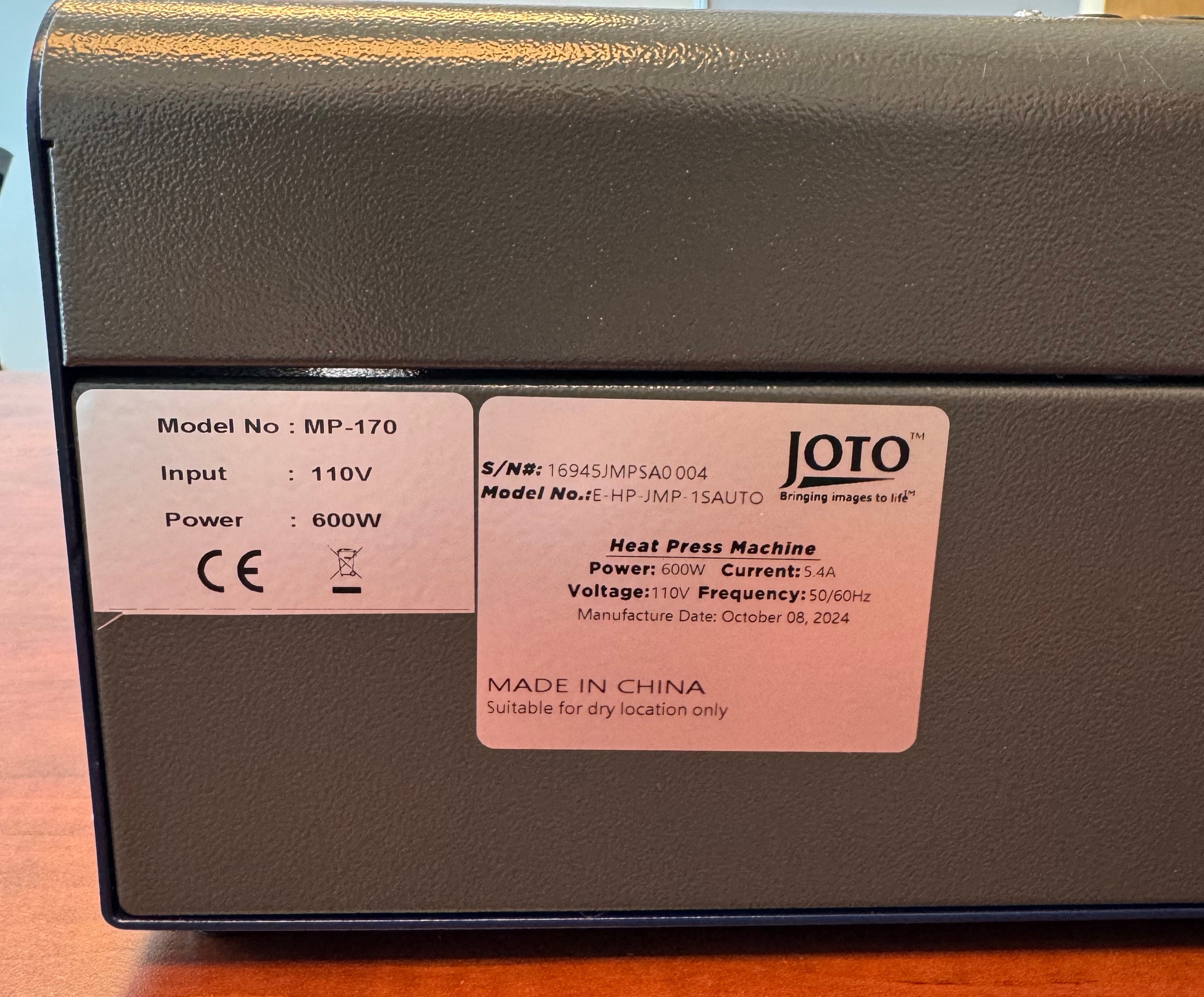

Mug presses are the go-to solution for turning plain drinkware into standout products. Their curved heating elements are built to wrap designs evenly around the surface, ensuring sharp edges and bold colors that last. Ideal for coffee mugs, travel cups, and specialty drinkware, these machines simplify the sublimation process so you can achieve consistent results every time. They heat quickly, maintain stable temperatures, and offer adjustable settings to handle different sizes and materials with ease. Compact yet powerful, mug presses are a smart fit for home studios as well as professional shops. Whether producing small personalized gifts or fulfilling larger promotional orders, they keep workflows smooth and efficient. With dependable performance, local stock, and Joto’s expert support, this collection makes it simple to expand your business while delighting customers with drinkware they will love to use daily.