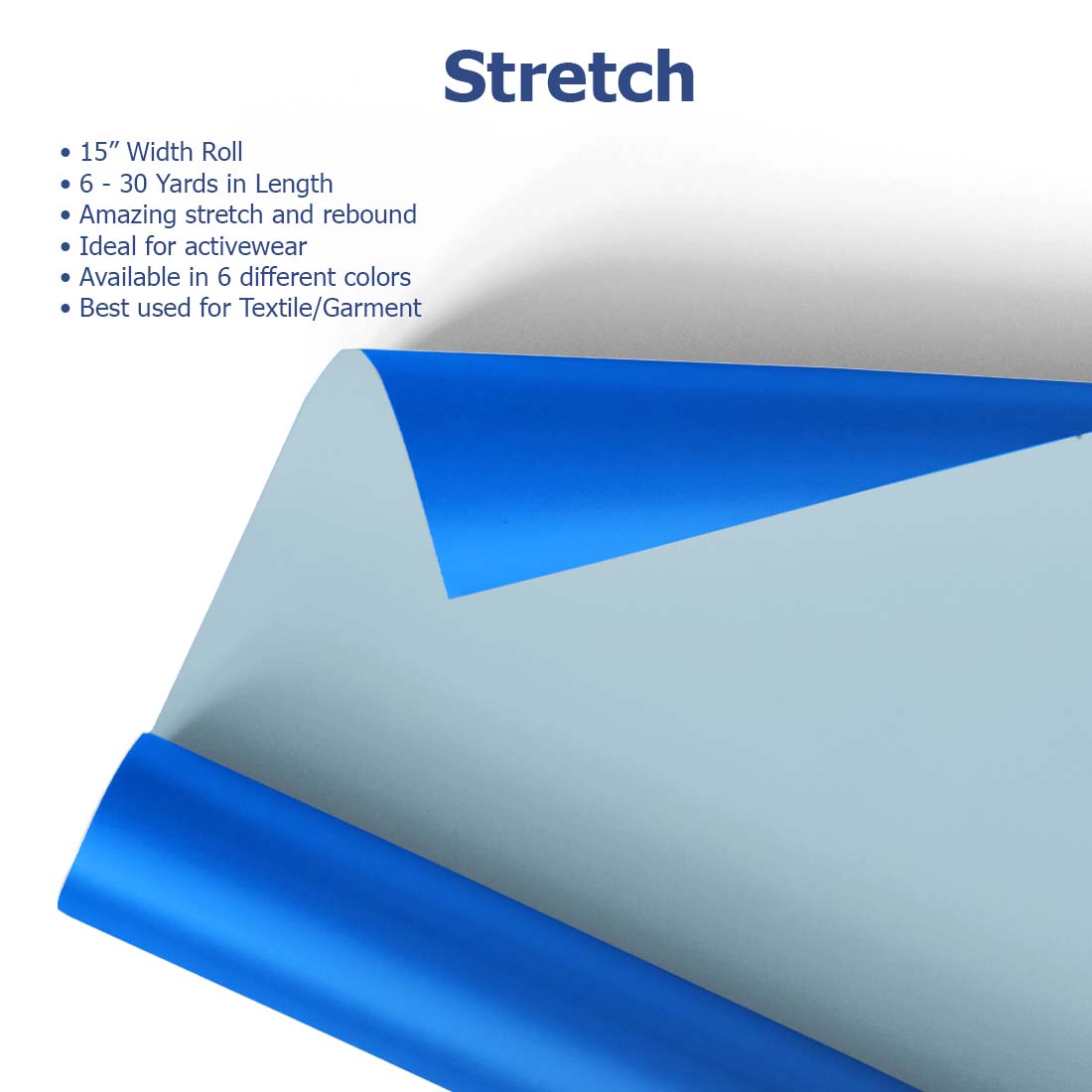

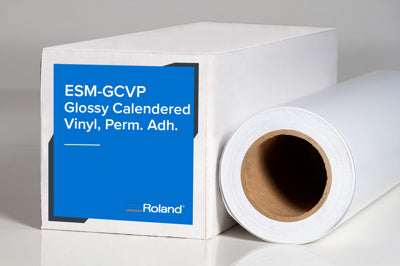

Vinyl cutters are specialized machines used to cut designs out of vinyl sheets. These designs can be used for creating heat transfer vinyl (HTV) for T-shirts, making stickers, banners, logos, and signage. Joto’s vinyl cutters, for example, offer dual-use functionality, allowing you to work with both T-shirt flex and sign vinyl.

Joto’s vinyl cutters are designed to meet all your vinyl application needs with top-notch precision.

Our easy-to-use desktop cutters and plotters ensure efficient cutting of heat transfer vinyl, allowing you to focus on producing personalized merchandise and growing your business. These dual-use machines can handle both T-shirt flex and sign vinyl, enabling you to create high-quality products and promote your business with ease.

Utilize the optical eye technology for print and cut applications, such as stickers, banners, and logo designs. Plus, all Joto cutters come with free cutting software, ensuring a seamless experience from start to finish.

What are vinyl cutters used for?

What types of vinyl can I cut with Joto vinyl cutters?

Do Joto vinyl cutters come with software?

What is optical eye technology?

Can I use Joto vinyl cutters for both small and large projects?

What accessories are available for my vinyl cutter?

How do I maintain my vinyl cutter?

What is the difference between desktop and larger vinyl cutters?

Can I use vinyl cutters for print-and-cut applications?

What is the price range for vinyl cutters?