Customizing your own T-shirts is not only a fun way to showcase your unique style but also an efficient method for producing professional-grade results. With a heat press machine, the process becomes simple and fast. In this guide, we’ll walk you through the steps to successfully heat press a T-shirt, from setting up your machine to peeling off the transfer paper, ensuring perfect prints every time.

How to Use a Heat Press Machine Step by Step to Print Your Own Shirts

1. Prepare Your Design and Materials

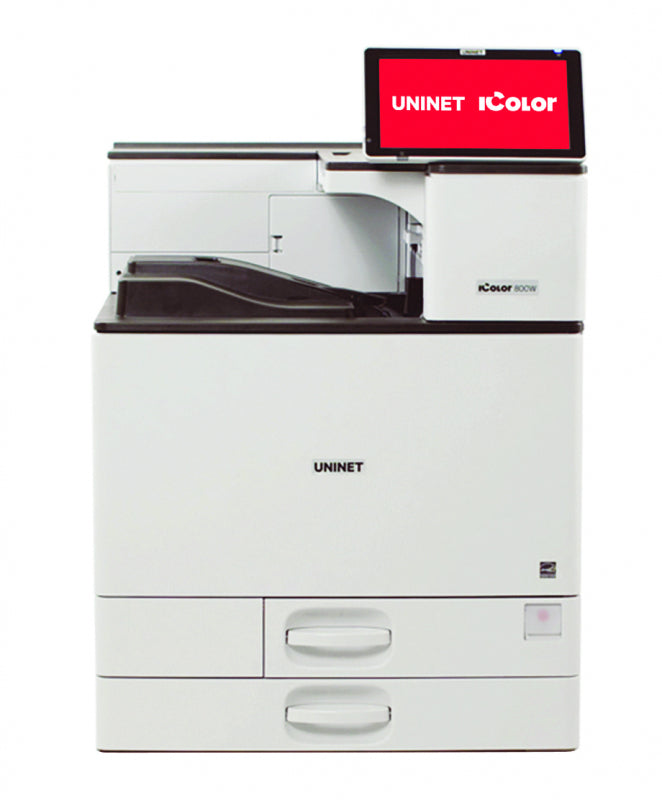

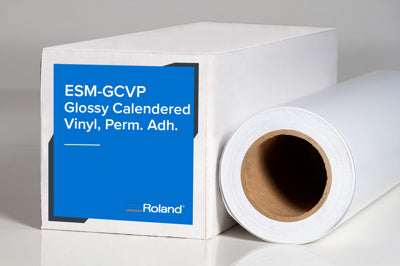

Start by selecting a high-quality image or design that you want to transfer onto your T-shirt. Depending on your project, use either sublimation transfer paper or heat transfer vinyl (HTV). Print your chosen design using a sublimation printer, and if needed, trim your design with a precision knife to remove any excess material for a cleaner look.

2. Set Your Heat Press Settings

Turn on your heat press and adjust the temperature, time, and pressure settings according to the type of transfer material and fabric you're using. Be sure to refer to the Joto Imaging Supplies product page for the recommended settings, or reach out to us for personalized help.

3. Arrange and Pre-Press Your Shirt

Place your T-shirt flat on the lower plate of the heat press, ensuring it’s wrinkle-free. To prepare the fabric, pre-press the shirt for a few seconds to remove any moisture and smooth out the surface, ensuring better adhesion of your design.

4. Position Your Transfer on the Shirt

Carefully align your design on the T-shirt, making sure it’s centered. Place the transfer paper with the design face-down on the fabric. Double-check that your design is properly positioned to avoid any mistakes.

5. Apply Heat and Pressure

Lower the top plate of your heat press and allow the set temperature, time, and pressure to transfer your design onto the T-shirt. Be sure to follow the recommended pressing time to achieve optimal results.

6. Peel the Transfer Paper or Carrier Sheet

Once the heat press timer goes off, carefully open the machine. Gently peel off the transfer paper or carrier sheet according to the instructions, which will indicate whether to peel hot or cold for the best outcome.

Why Use a Heat Press for Making T-Shirts?

Heat pressing is a cost-effective and versatile method for customizing T-shirts, ideal for small to medium-sized projects. Whether you're creating custom T-shirts, mugs, tote bags, or other items, a heat press allows for quick production with minimal setup and high-quality results.

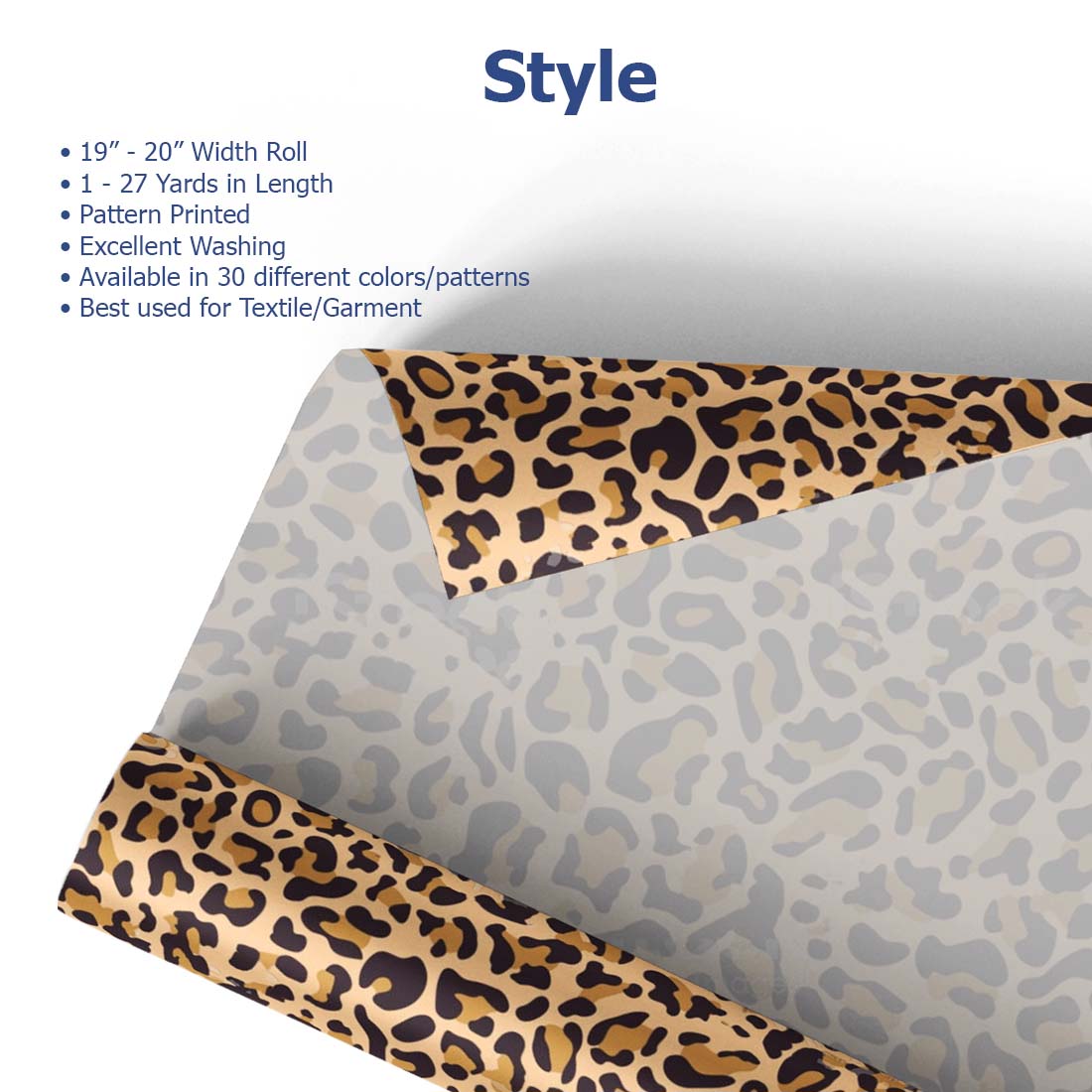

How to Select Materials for Heat Press T-Shirt Printing

Choosing the right materials is essential for successful heat pressing. For sublimation printing, use polyester fabrics or Pearl Coating™ materials. If you’re using HTV (heat transfer vinyl), it works best on cotton or cotton blends. The fabric must be compatible with your transfer type to ensure proper adhesion and vibrant prints.

Heat Press Options for T-Shirt Printing

At Joto Imaging Supplies, we offer a variety of heat presses tailored for T-shirt printing, ensuring you can find the perfect machine for your needs:

- ClamShell Presses:

- ClamShell 16" x 20": Ideal for printing larger designs on T-shirts. Its simple operation and compact design make it great for medium to high-volume projects.

- ClamShell 15" x 15": Perfect for smaller projects, this press is easy to use and space-efficient, ideal for hobbyists or small businesses.

- Swing-Away Presses: Featuring a top platen that swings away from the lower plate, these presses offer better visibility and precise placement, perfect for complex or layered designs.

- Shuttle Presses: Designed for increased efficiency, shuttle presses feature dual lower plates, allowing you to load one shirt while the other is being pressed. Ideal for high-production environments.

- Cap & Pocket Presses: These specialized presses are perfect for adding logos or designs to caps, pockets, and other small areas of T-shirts.

With a range of sizes and features, these heat presses are perfect for creating high-quality custom T-shirts, whether you're a hobbyist or running a professional business.

Conclusion:

Using a heat press to create custom T-shirts is an easy, efficient, and professional method for anyone looking to get creative. Follow these steps, use high-quality materials from Joto Imaging Supplies, and enjoy durable, vibrant designs that last. For any product assistance or inquiries, don’t hesitate to check out Joto’s product pages or contact our team for expert advice!