Heat transfer paper vs. sublimation printing - the eternal debate for small and medium print shops looking to create stunning, full-color designs on various substrates.

But what's the ideal technique for your enterprise?

In this blog post, we will dive deep into the world of heat transfer paper and sublimation printing, exploring their advantages, comparing their differences, and evaluating cost considerations. Comparing the advantages and differences between heat transfer paper and sublimation printing, let us assess their respective costs to decide which is best for your next project.

So, buckle up as we take a closer look at these two popular printing techniques!

1. Heat Transfer Paper: Advantages

Let's talk about heat transfer paper, shall we? This fantastic option is perfect for small and medium print shops looking to produce vibrant, full-color prints quickly and cost-effectively. But wait, there's more.

Wide Range of Applications

You might be wondering; what type of projects is digital heat transfer paper suitable for? Well, there is heat transfer paper produced for most all standard office printing equipment. Yes, that is right, Color Laser Copiers, Color Desktop Laser Printers, and Color Ink Jet Printers to say the least. Versatility is the name of the game when it comes to today’s Digital Heat Transfer Papers. All of these can be applied to the items that your customers will love, including T-shirts, bags, wood boxes, and even mugs.

Compatible with Most Printers

No need to worry about purchasing specialized equipment here. Heat transfer papers are compatible with most desktop inkjet or laser printers and Color Laser Copiers available on the market. Talk about convenience!

Affordability at Its Finest

One major advantage of using heat transfer paper is its affordability compared to other printing methods. It enables small businesses to produce quality personalized goods without straining the budget. Plus, the materials needed are readily available and easy to source.

So, there you have it! Heat transfer paper offers numerous advantages for small and medium print shops looking to create vibrant full-color prints quickly and cost-effectively. Give it a try and see the fantastic results for yourself.

2. Sublimation Printing: The Ultimate Solution for Top-Notch Quality and Durability

Alright, let's dive in.

If you're looking for a printing process that will level up your printing game, sublimation printing might just be the answer to all your prayers.

But why?

Let’s break down its incredible benefits for you:

Superior Image Quality

Sublimation printing sets itself apart with its ability to produce stunningly detailed images with exceptional color accuracy and vibrancy on polyester fabrics and coated items.

This means that even the most intricate designs will come out looking sharp and true-to-life. There are also hundreds of wearables and printables designed specifically for sublimation.

Unmatched Durability

Tired of prints fading or peeling off after a few washes? Fret not. With sublimation printing, the ink dyes the substrate, becoming part of the product itself. This ensures that the printed image will be long-lasting and can withstand multiple washes without losing its charm.

Versatility Galore

Beyond t-shirts and apparel, sublimation printing opens a whole new world of possibilities for your print business. From mugs and water bottles to phones and pillowcases, this technique lets you expand your product offerings like never before.

Eco-Friendly Printing

Sublimation printing is much more eco-friendly than many other techniques that use solvents or petroleum-based films. It uses water-soluble, dye-based inks, meaning fewer chemicals and less waste—a win-win for your business and the environment.

Eager to learn more about this game-changing technique? Check out this comprehensive guide on sublimation printing here.

If you're after superior-quality, enduring prints, then why not give sublimation printing a try?

3. Heat Transfer Paper vs. Sublimation Printing: Comparison

Let's explore the distinctions between these two popular printing techniques and decide which one is most suitable for your print shop.

We'll break down their differences and help you determine which method aligns best with your shop’s needs. Ready? Let's go.

Quality & Detail

Sublimation printing takes the lead in image quality, allowing for more detailed images with greater color accuracy and vibrancy than traditional heat transfer paper—though substrate limitations do exist.

Durability & Longevity

When durability is key, sublimation printing on polyester substrates wins again. The process results in prints that are more resistant to fading, cracking, or peeling over time.

Ease of Use & Setup Time

-

Heat Transfer Paper:

- Easier setup—simply print your design on the special paper and apply it using a heat press.

- Ideal for beginners due to the minimal learning curve.

-

Sublimation Printing:

- Requires an initial investment in equipment like a dye-sublimation printer, special ink, and a heat press. Despite a steeper learning curve, the benefits can outweigh the challenges.

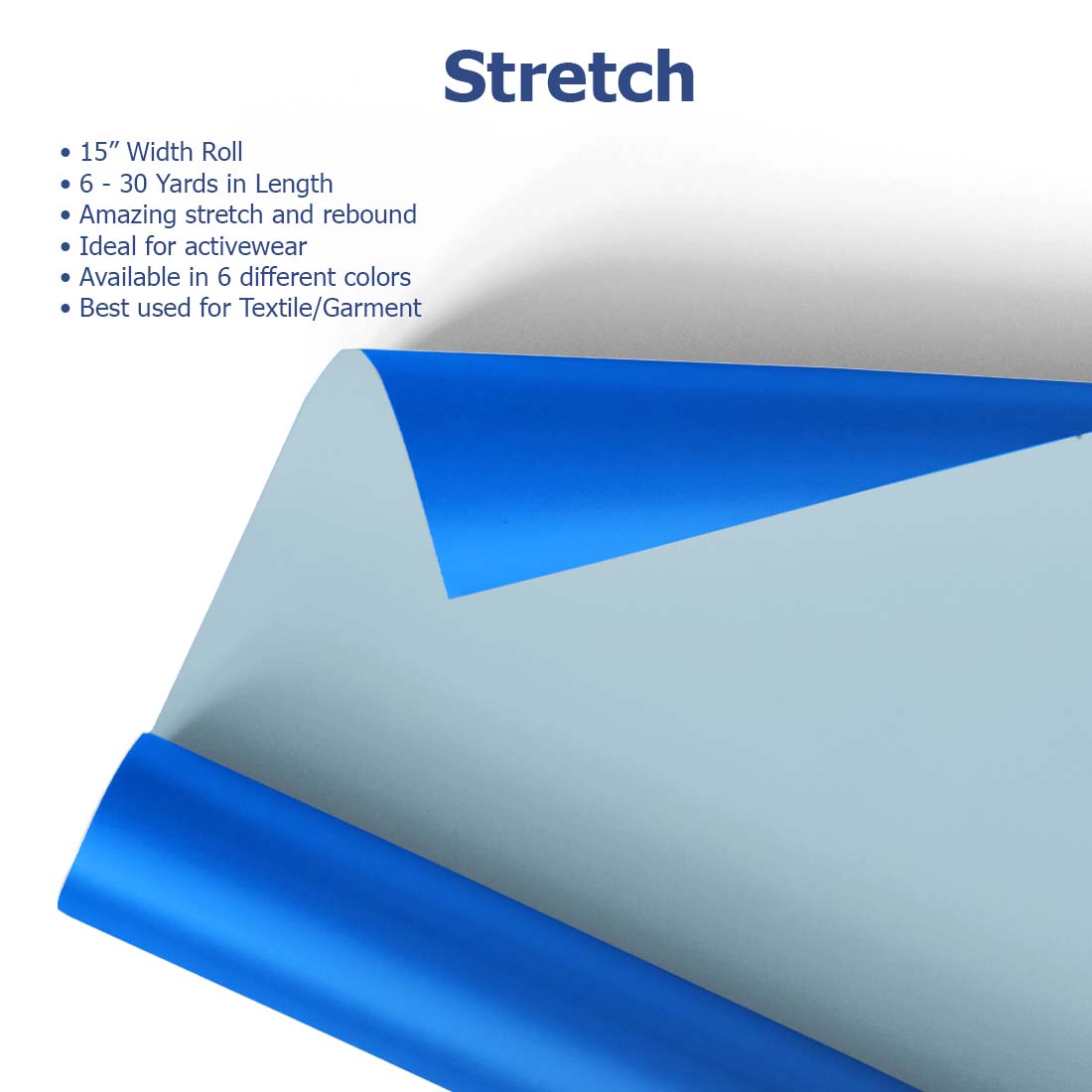

Suitable Materials & Applications

Heat transfer paper works best on cotton or polyester blend fabrics, while sublimation printing is more versatile—ideal for ceramics, metal sheets, glass panels, and even some rigid plastics.

In summary: If quality and durability are top priorities, sublimation printing is the way to go (keeping in mind the need for polyester or coated substrates). However, if ease of use, quick setup, and lower initial costs are crucial, heat transfer paper might be your best fit.

Cost Considerations: Finding the Right Balance for Your Print Shop

Let's talk about money. As a savvy print shop owner, you understand that cost is essential when selecting between these two methods. We’ve compared the financial aspects of both to help you make an informed decision based on your needs.

Heat Transfer Paper: The Budget-Friendly Choice

If affordability is your top priority, heat transfer paper might be just what you need. It requires minimal setup time and uses low-cost materials—many small businesses find this method perfect for producing eye-catching prints on apparel without breaking the bank.

Sublimation Printing: Investing in Quality & Durability

On the other hand, if high-quality, detailed prints and the ability to decorate hard surfaces (like mugs) are more important than the initial costs, sublimation printing is worth considering as an investment in long-term success. Though the upfront cost is higher, the durability and superior quality can pay off over time.

Finding Your Perfect Balance

The key is balancing affordability with your design and quality needs. If short-term savings are crucial, heat transfer paper may be your best bet. But if long-lasting, high-quality prints are your goal, exploring sublimation printing could be the right choice.

FAQs in Relation to Heat Transfer Paper vs. Sublimation Printing

Which is better: Heat Transfer Paper vs. Sublimation Printing?

The best option depends on your needs and what you plan to decorate. Digital heat transfer paper works on a wide range of fabrics and softer surfaces, though its print quality may be limited compared to sublimation. Sublimation offers higher quality and durability, but it requires polyester or coated materials.

What is the difference between heat transfer screen print and sublimation?

Direct Screen Printing: Applies liquid ink directly onto fabric through a mesh stencil, then cures it in a heated drying tunnel.

Screen Printed Heat Transfers: Produced by screen printing on a special release paper, then applied to fabric using a heat press.

Sublimation Printing: Uses heat-sensitive inks that turn into gas under high temperatures, infusing into polyester fibers or coated surfaces for a permanent bond. While screen printing is versatile, sublimation yields more vibrant, durable colors.

Can you use regular printing paper to produce Sublimation Heat Transfers?

No, you cannot. Sublimation printing requires specially coated sublimation paper that keeps the dye-based inks on the surface long enough to transfer fully onto the substrate.

What are the disadvantages of sublimation printing?

Sublimation works best on light-colored polyester fabrics or coated hard substrates. It doesn’t perform well on dark garments, as the decoration will not be visible. In such cases, other methods like direct-to-garment or screen printing might be more suitable.