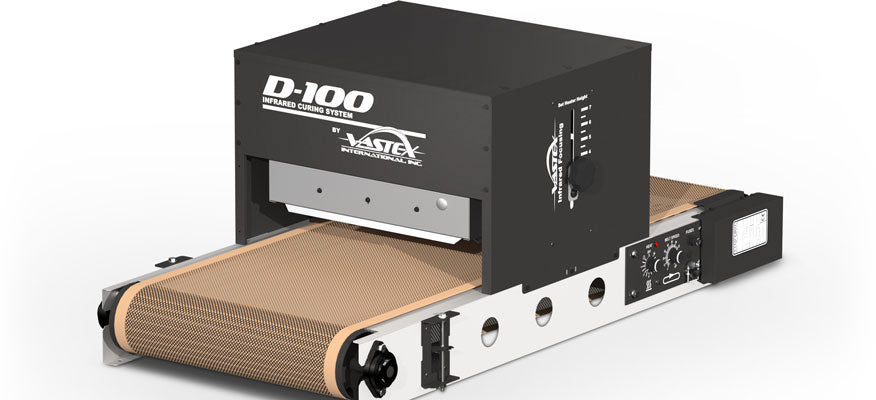

Compact d-100 18" conveyor dryer delivering precise infrared curing

The Vastex D-100 is a compact, tabletop infrared conveyor dryer with an 18" (46 cm) wide Teflon-coated fiberglass belt and precise variable controls. Designed for efficient curing of plastisol, discharge, and DTF inks, it delivers exceptional output in a small workspace.

With adjustable heater height, tilt, heat intensity, and belt speed, this reliable dryer ensures uniform curing, high throughput, and flexible integration into production workflows.

Key Features:

- 18" (46 cm) belt width and 16" (41 cm) heater width optimize curing area for garments and transfers :contentReference[oaicite:0]{index=0}

- Adjustable heater height, tilt, heat intensity, and conveyor speed for precise control :contentReference[oaicite:1]{index=1}

- Compact footprint under 8 sq ft (≈ 2.44 m²), ideal for limited spaces :contentReference[oaicite:2]{index=2}

- High-curing capacity: over 110 plastisol shirts/hour, 50+ discharge shirts/hour, and effective DTF adhesive curing :contentReference[oaicite:3]{index=3}

- Smart Teflon-coated fiberglass belt with tracking system ensures uninterrupted operation :contentReference[oaicite:4]{index=4}

- Dense infrared coil pattern with heat shields delivers even temperature across the chamber :contentReference[oaicite:5]{index=5}

- Available in 120 V (NEMA 5-15P) or 240 V configurations for versatile installation :contentReference[oaicite:6]{index=6}

- 15-year heater warranty and 3-year defect warranty for long-term reliability :contentReference[oaicite:7]{index=7}

Personalization Options:

Optimize your curing setup by pairing the D-100 with optional stands or powered exhaust systems. This flexibility ensures efficient workflows, particularly for DTF transfers, textile production, and mixed-media printing.

Printing Compatibility:

- Supports plastisol, discharge, and DTF adhesive curing—great for diverse print shops :contentReference[oaicite:8]{index=8}

- Optional powered exhaust recommended for DTF and water-based inks to manage fumes and moisture :contentReference[oaicite:9]{index=9}

- Expandable via modular extensions or exhaust hood for evolving production needs :contentReference[oaicite:10]{index=10}

Product Specifications:

- Belt width: 18" (46 cm)

- Heater width: 16" (41 cm)

- Curing capacity: 110+ plastisol shirts/hour; 50+ discharge shirts/hour; efficient DTF curing

- Adjustability: Variable speed, heat intensity, heater height & tilt

- Dimensions (assembled): 46" L × 24" W × 24" H (119 × 61 × 61 cm); Weight: ≈ 89 lb (40.4 kg) :contentReference[oaicite:11]{index=11}

- Voltage options: 120 V (NEMA 5-15P) or 240 V (NEMA 6-15P) :contentReference[oaicite:12]{index=12}

- Heater warranty: 15 years | Defect warranty: 3 years :contentReference[oaicite:13]{index=13}

- Pack Quantity: 1 unit

Important Usage Notes:

- Always review the instruction manual and safety guidelines before operation :contentReference[oaicite:14]{index=14}

- Ensure the belt is moving before turning on the heat; avoid loading excessive weight on the conveyor :contentReference[oaicite:15]{index=15}

- Allow cooling to 300 °F (149 °C) or wait 10–15 minutes before turning off the conveyor :contentReference[oaicite:16]{index=16}

- Install exhaust systems when curing DTF or moisture-heavy inks for optimal performance :contentReference[oaicite:17]{index=17}

- Power down at the main disconnect after use and restrict access to authorized personnel :contentReference[oaicite:18]{index=18}

Perfect For:

- Small print shops or mobile operations seeking compact, reliable infrared curing

- Businesses handling mixed-media printing including plastisol, discharge, and DTF transfers

- Studios in need of expandable, modular curing solutions with strong support and warranty

Handling & Storage Recommendations:

- Place on a stable, heat-resistant surface with proper ventilation

- Allow full cooldown before handling or moving

- Clean and maintain heat shields and belt tracking for consistent performance

| Peel | |

|---|---|

| Equipment | |

| Image | |

| Pressure | |

| Application Temperature | |

| Time |