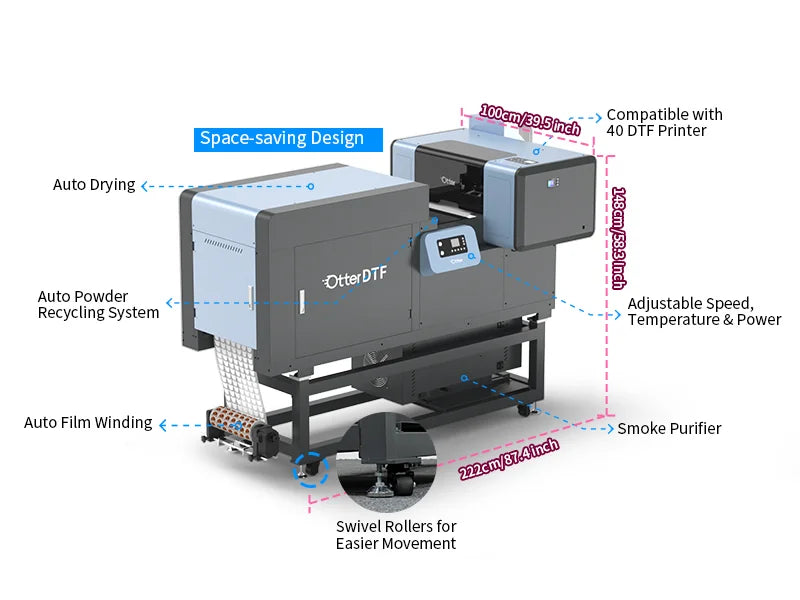

OtterPro™ DTF 24 All-in-One System

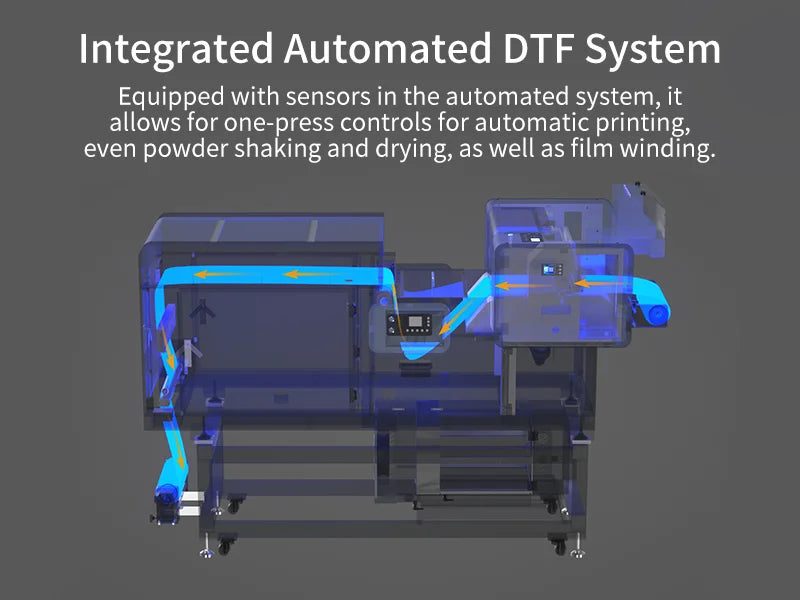

The OtterPro™ DTF 24 All-in-One System is a professional direct-to-film (DTF) printing solution designed to streamline production by combining printing, automatic powder application, and curing in one integrated unit. Built for businesses ready to scale, this 24-inch system provides high-volume output, vibrant prints, and unmatched efficiency for apparel decorators and promotional product suppliers.

Engineered with advanced reliability and ease of use, the OtterPro™ DTF 24 is optimized for both beginners and established shops. With starter supply recommendations included, the system ensures operators can begin production immediately and sustain consistent output as they grow.

Key Features:

- 24-inch all-in-one DTF printer with integrated powder shaker and curing oven

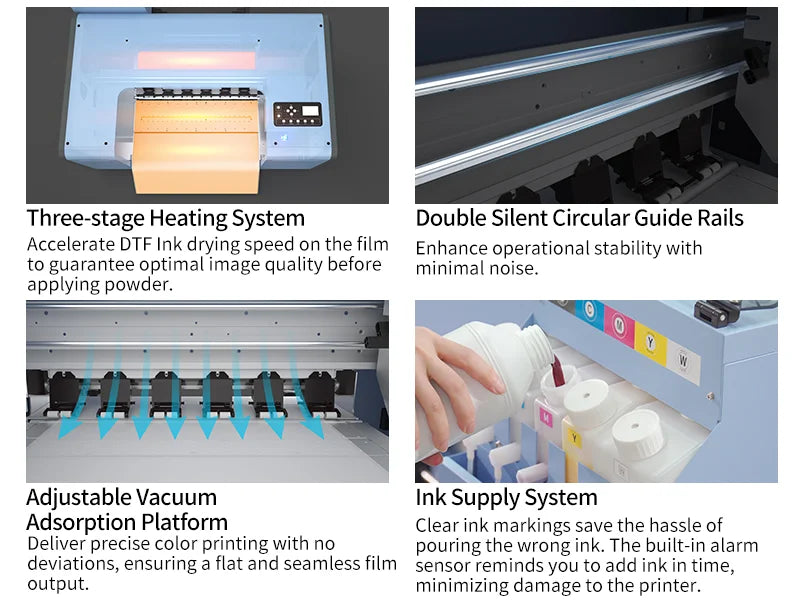

- High-resolution output with vivid color and sharp details

- Continuous workflow reduces manual handling and increases efficiency

- Supports a wide range of fabrics including cotton, polyester, blends, and nylon

- Low-maintenance design with accessible components

- Professional reliability suitable for both startups and production-scale businesses

Personalization Options:

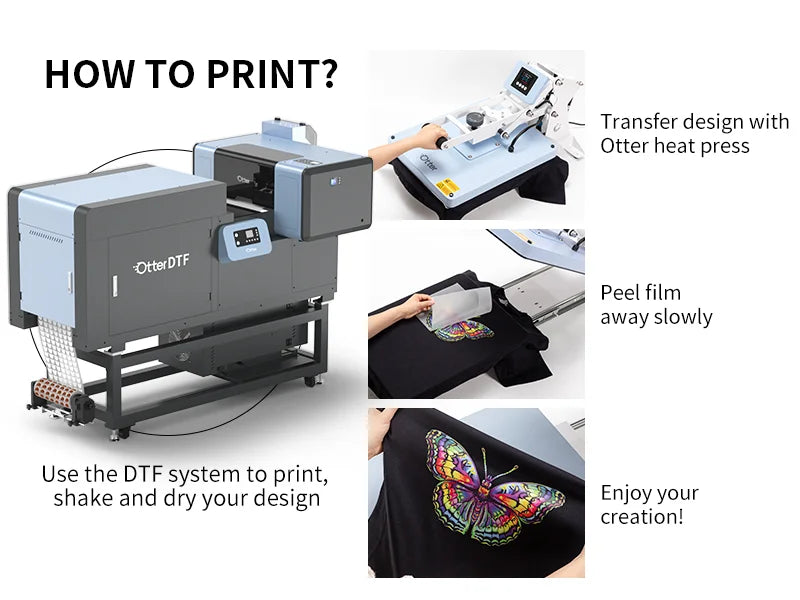

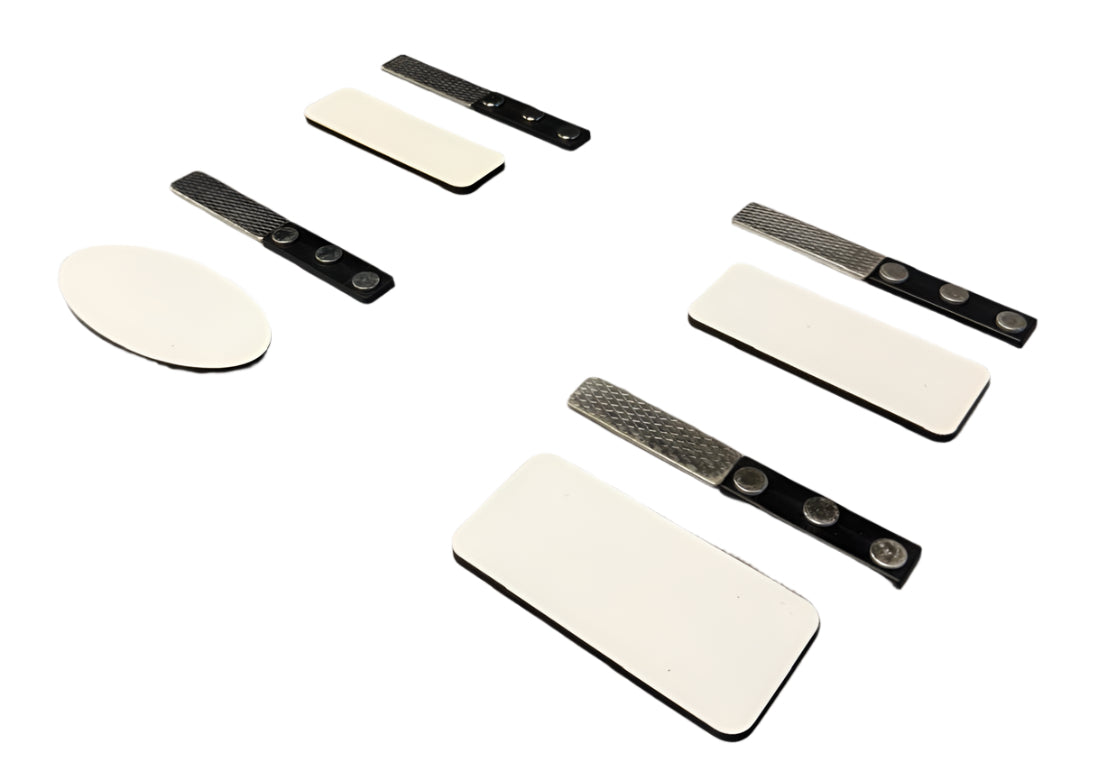

The OtterPro™ DTF 24 allows the creation of custom full-color transfers for garments and accessories of any fabric type. Ideal for t-shirts, hoodies, sports uniforms, tote bags, and branded merchandise, it enables businesses to serve diverse markets with professional-grade results that resist fading and cracking.

Printing Compatibility:

- Direct-to-film: PET transfer films up to 24 inches wide

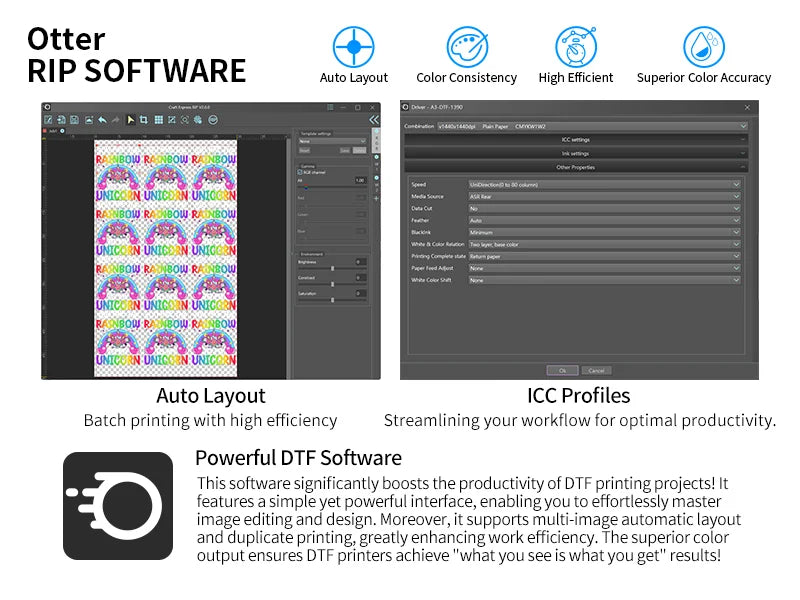

- Works with RIP software for precise color management and efficient workflow

Product Specifications:

- System Type: 24-inch all-in-one DTF printer with shaker and oven

- Ink System: DTF pigment inks (CMYK + White)

- Print Resolution: High-definition output for detailed graphics

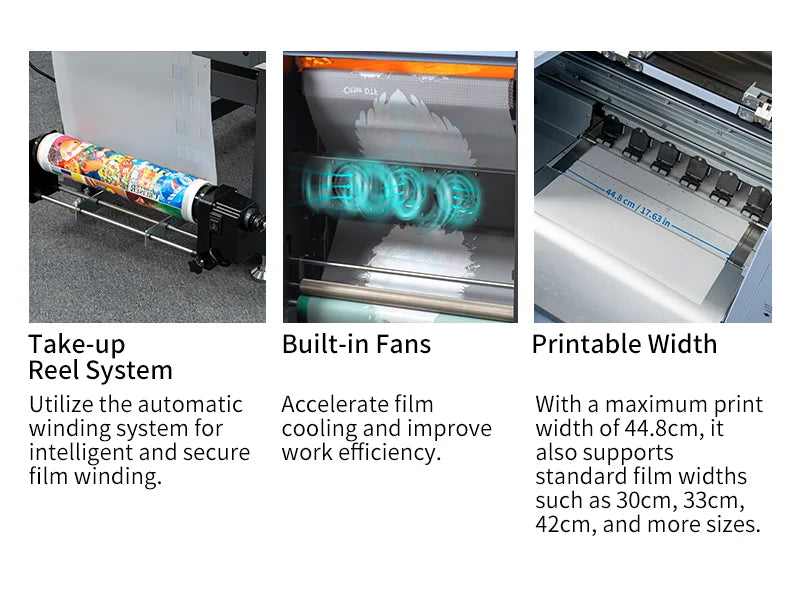

- Media Width: Up to 24 inches PET transfer films

- Supported Fabrics: Cotton, polyester, blends, nylon, and more

- Workflow: Integrated powder application and curing

- Software: RIP for color profiling and production control

- Starter Recommendations: Includes guidance on film, powder, and ink quantities for beginners

- Dimensions: Compact design for mid-size shops

- Weight: As detailed in brochure specifications

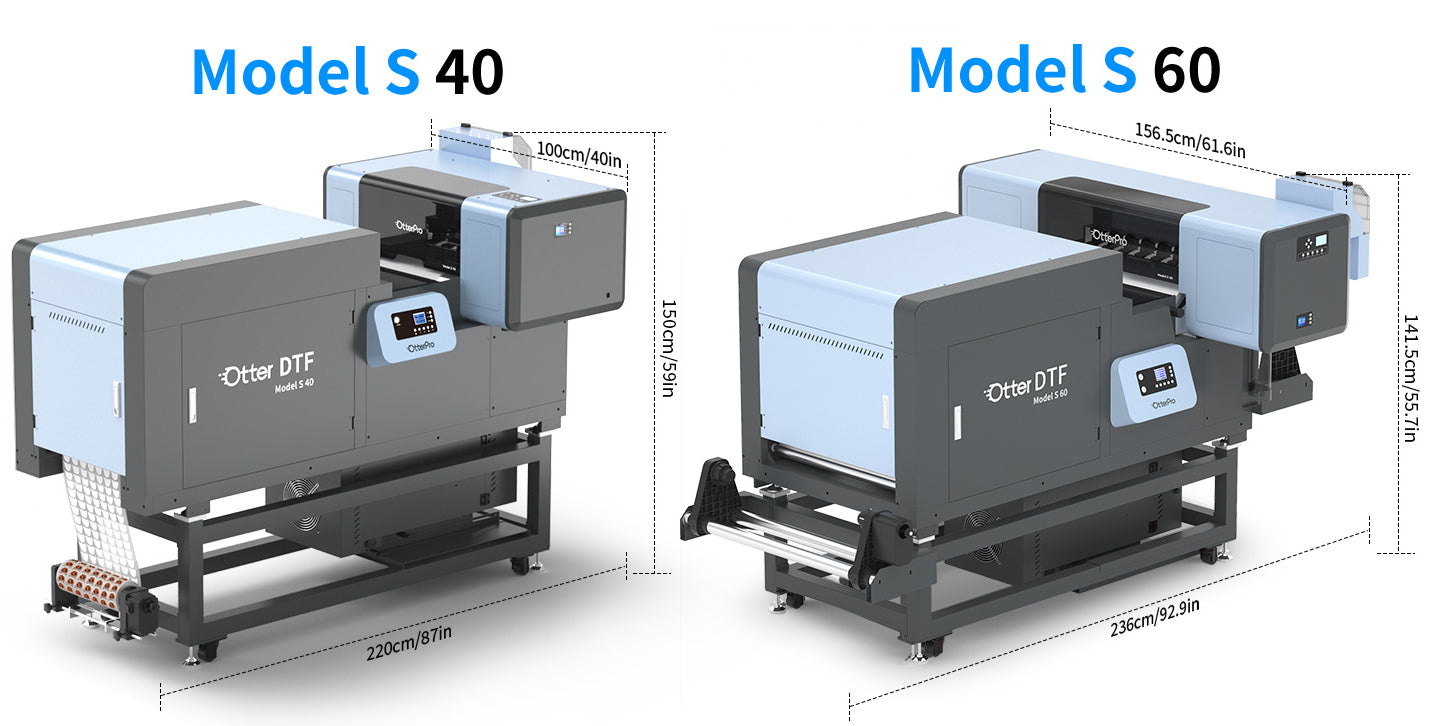

What’s Included – OtterPro S40 Package:

- 2 Sets of OtterPro Ultra Ink (CMYK+W, 2000ml/color)

- 4 Bags OtterPro DTF Powder (1kg each)

- 2 Rolls of DTF Film (42cm x 100m, Double-sided Matte)

- 2 Packs of DTF Film (30cm x 10m)

- Essential replacement parts: dampers, ink tubes, cap top, encoder strip, ink filter, cleaning wipers

- 1L Printhead Cleaning & Protection Fluids

- 6 Hours of Professional Installation & Training

- 6-Month Printhead Warranty (terms apply)

- Optional On-Site Installation

What’s Included – OtterPro S60 Package:

- 6 Bags OtterPro DTF Powder (1kg each)

- 3 Rolls of DTF Film (23.6" x 393.7")

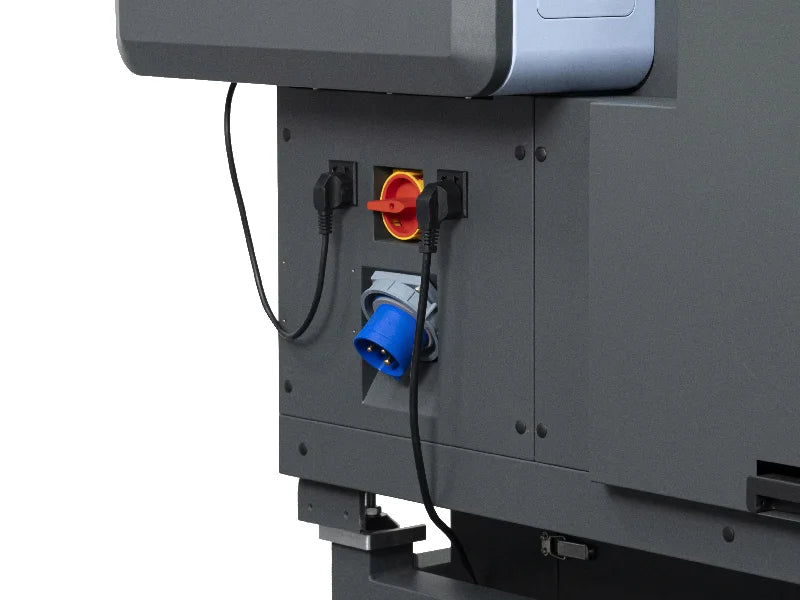

- 1 DTF 4000W Voltage Converter (220V to 110V)

- Extended Ink Tubing for wider print format

Important Usage Notes:

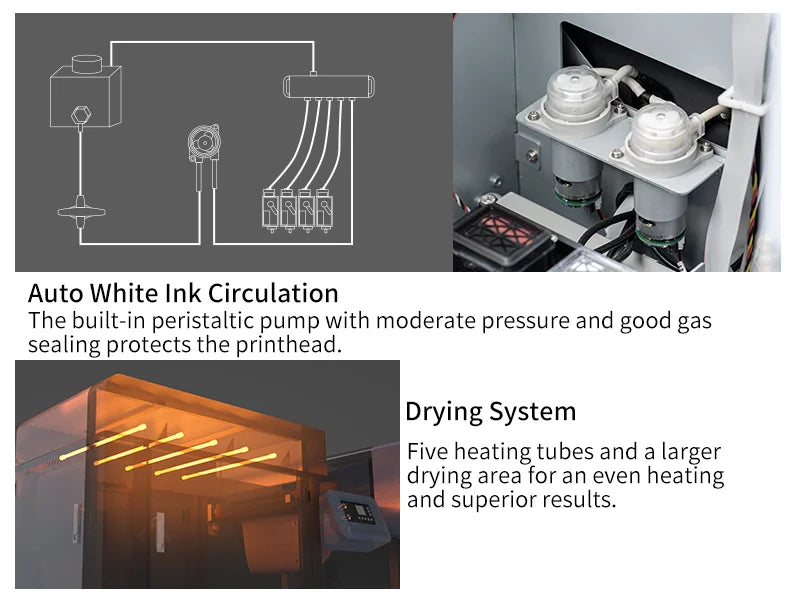

- Shake white ink daily to prevent pigment settling

- Perform regular nozzle checks and cleanings to maintain consistency

- Use recommended PET film sizes and curing times for durability

- Ensure powder is evenly distributed before curing

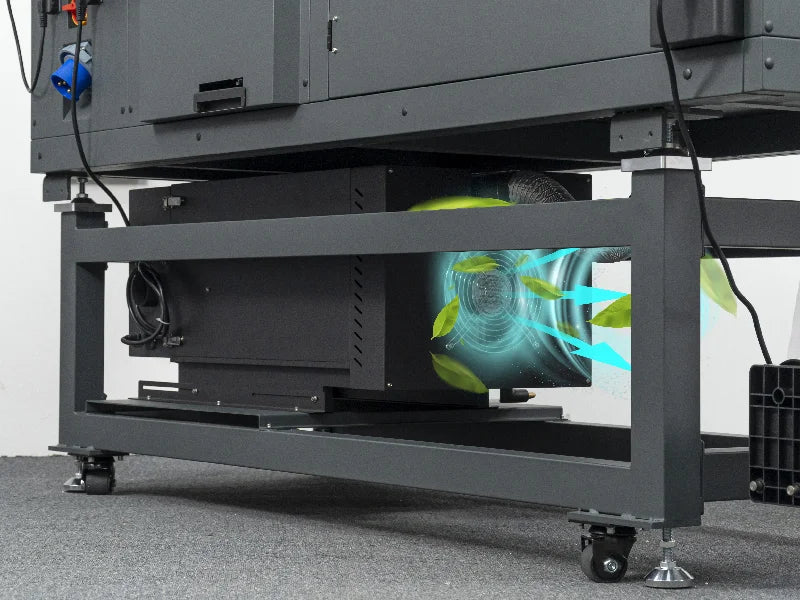

- Maintain proper workspace ventilation during curing

Perfect For:

- Growing print shops seeking a scalable DTF production system

- Startups entering the custom apparel market with professional-grade equipment

- High-volume production of uniforms, sportswear, and promotional products

- Shops requiring reduced manual handling through an all-in-one solution

Handling & Storage Recommendations:

- Store inks in a cool, dry environment away from direct sunlight

- Protect PET films from dust, humidity, and temperature fluctuations

- Follow starter supply guidelines to maintain balanced production flow

- Clean the powder application and curing components regularly

- Keep the workspace temperature-controlled for optimal performance

| Dimensions | 220 x 100 x150 cm / 87 x 40 x 59 in (Printer Included) |

|---|---|

| Power Consumption | 2500W MAX±5 |

| Product Specification | Epson i1600 (Model S40) High precise printhead for high productivity and high image quality.Ideal Width for a Perfect Print S40: 0-448mm/l7.6in Stable & Quiet DC Motor Controller Double Silent Circular Guide Rails Steel Body Safe & Intelligent White Ink Auto Circulation Stirring System Automatic Cleaning System Alarm System |

| Voltage | 220V 50Hz |

| Width | 0-448mm/17.6in Max |

| Peel | |

|---|---|

| Equipment | |

| Image | |

| Pressure | |

| Application Temperature | |

| Time |