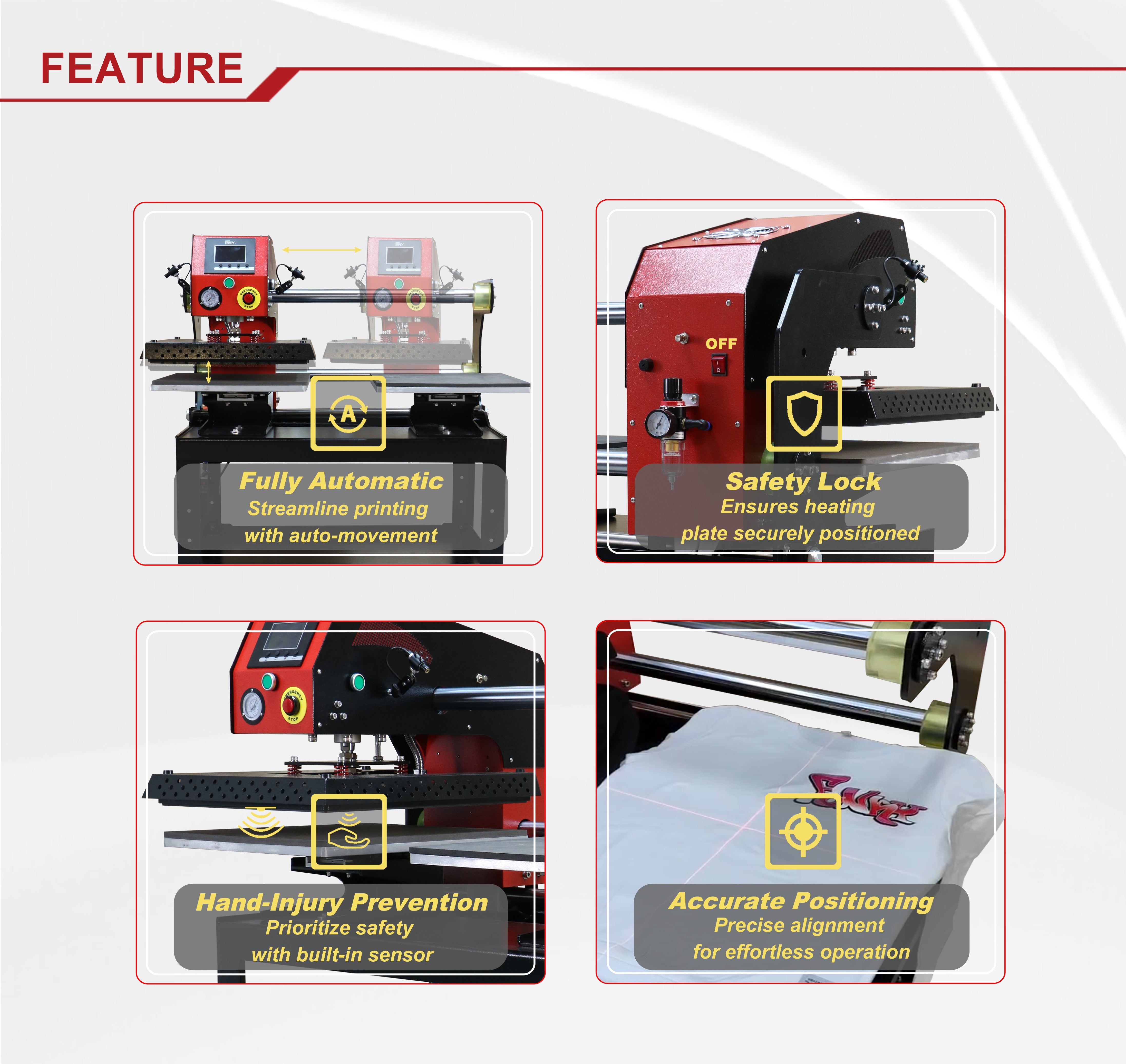

Dual-station auto shuttle heat press with laser alignment for peak productivity

Increase throughput and precision with the Dual-Station Auto Shuttle Heat Press with Stand & Laser, designed for high-volume environments. Its pneumatic system ensures consistent pressure, while the dual-station shuttle design allows one platen to be prepared while the other presses, maximizing efficiency.

Equipped with a built-in laser alignment system and digital controls, this press delivers unmatched accuracy and repeatability for sublimation, HTV, and DTF applications.

Key Features:

- Dual-station shuttle system for nonstop operation and higher productivity

- Pneumatic auto-open mechanism with consistent, even pressure

- Laser alignment system ensures precise positioning of designs

- Digital time and temperature controls with easy-to-read display

- Heavy-duty stand provides stability for continuous use

Personalization Options:

Ideal for sublimation printing, HTV transfers, and DTF applications. The laser guide streamlines artwork placement, guaranteeing accurate, vibrant results on textiles, hard goods, and thicker substrates.

Printing Compatibility:

- Compatible with Joto sublimation papers, inks, MultiPrint™ and MultiCut™ transfers

- Works with a wide range of textiles, ceramics, and coated hard substrates

- Pneumatic pressure system ensures repeatable results in high-volume workflows

Product Specifications:

- Platen Size: 16" x 20" (40.6 cm x 50.8 cm)

- Dimensions: 53" x 33" x 59" (134.6 cm x 83.8 cm x 149.9 cm)

- Weight: 551 lbs (250 kg)

- Power: 1.8 kW / 220V

- Temperature Range: 0°F – 480°F (0°C – 249°C)

- Time Range: 0 – 999 seconds

- Air Compressor: Required, 100 PSI minimum (not included)

- Material: Industrial-grade steel

- Finish/Color: Black with precision laser system

- Microwave Safe: Not applicable

- Dishwasher Safe: Not applicable

- Pack Quantity: 1 unit

Important Usage Notes:

- Requires external air compressor delivering at least 100 PSI

- Do not exceed recommended settings for specific substrates

- Ensure shuttle path and laser area remain clear during operation

- Allow the machine to cool before cleaning or moving

- Keep in a dry, ventilated workspace to avoid electrical or pneumatic issues

Perfect For:

- Industrial-scale sublimation and HTV production

- High-volume apparel decoration with accurate alignment

- Shops requiring nonstop productivity and reliable precision

Handling & Storage Recommendations:

- Place on a reinforced, stable surface to support heavy weight

- Disconnect air and power sources when not in use

- Clean platens with a soft cloth after cooling, avoid abrasives

| Air Compressor | Yes (Required) |

|---|---|

| Amps | 15A |

| Available Platen Sizes | 16x20 |

| Brand | Joto |

| Compatible Technology | Heat Presses |

| Controller | GY-06 Digital Controller |

| Dependent Quantity | No |

| Dimension | 102x115x150cm |

| Dye Blocking | No |

| Environment | +5°C - +35°C / 30 |

| FCC Attribute | Yes |

| Features | Air Operated |

| Gross Weight | 215lbs (97kg) |

| Ink Configuration | CMY&HDK |

| Machine Type | Pneumatic Double Base Heat Press |

| Max Pressure | 4.98 lbs/in² (350g/cm²) |

| Max Temperature | 437F (225°C) |

| Packing Size | 41.34” x 37.4” x 27.56” (105cm x 95cm x 70cm) |

| Platen Size | 16" x 20" |

| Power | 1.6KW/ 1.8KW |

| Pressure Setting | Setting of pneumatic pressure |

| Printable Area | Up to 28mm Thickness |

| Printable Articles | Up to 1.20” (30mm) Thickness |

| Scope of Delivery | Transfer Press|Power Cable|Mounting for Compressor|Manual |

| Self-Weeding | No |

| SIP Attribute | Yes |

| Time Range | 0-999 seconds |

| Type of Press | Automatic Pneumatic Shuttle |

| Voltage | 120V/ 220V |

| Peel | |

|---|---|

| Equipment | |

| Image | |

| Pressure | |

| Application Temperature | |

| Time |