OtterPro™ DTF Printer

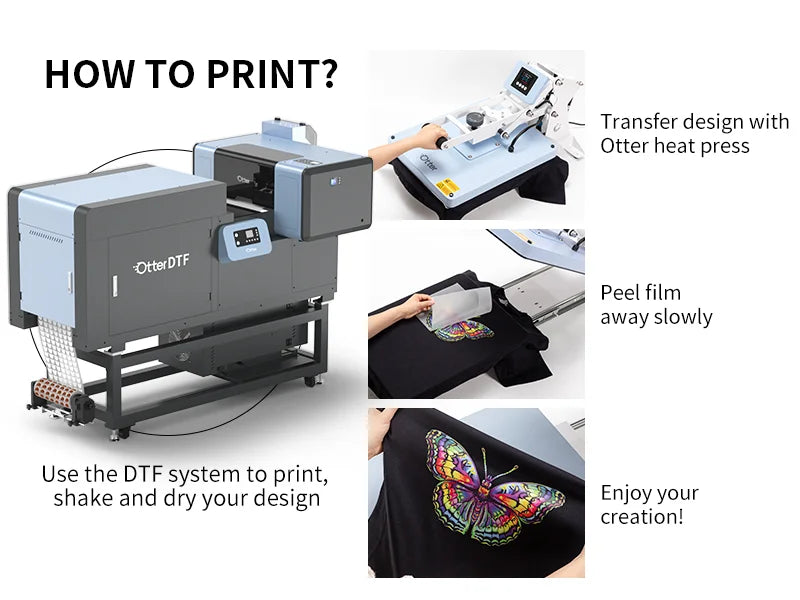

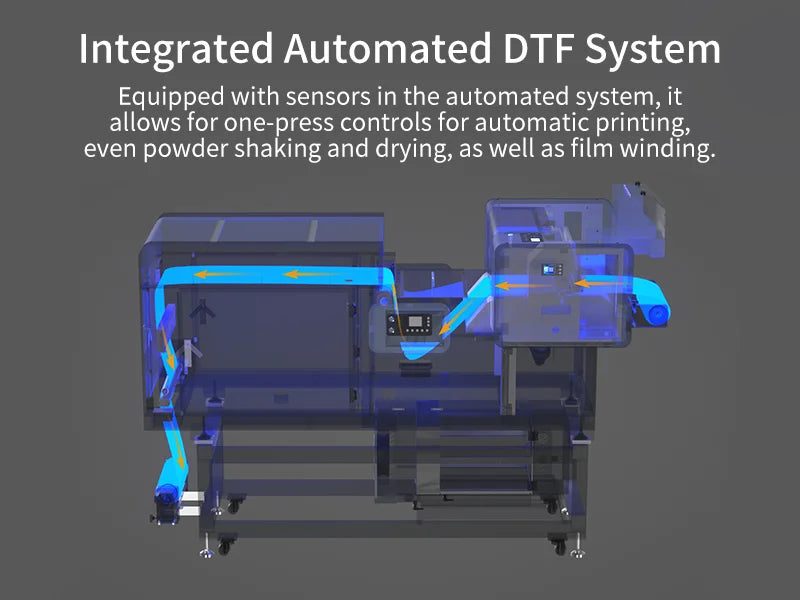

The OtterPro™ DTF Printer is a professional-grade direct-to-film (DTF) printing system engineered for high-volume production and reliable output. Designed as an all-in-one solution, it integrates printing, powder application, and curing in a single streamlined workflow, reducing manual handling and maximizing efficiency.

Built with durability and precision in mind, the OtterPro™ delivers vibrant, full-color transfers suitable for cotton, polyester, blends, nylon, and other fabrics. Whether you are a startup entering the DTF market or an established shop expanding production, this system ensures consistent results and scalable growth.

Key Features:

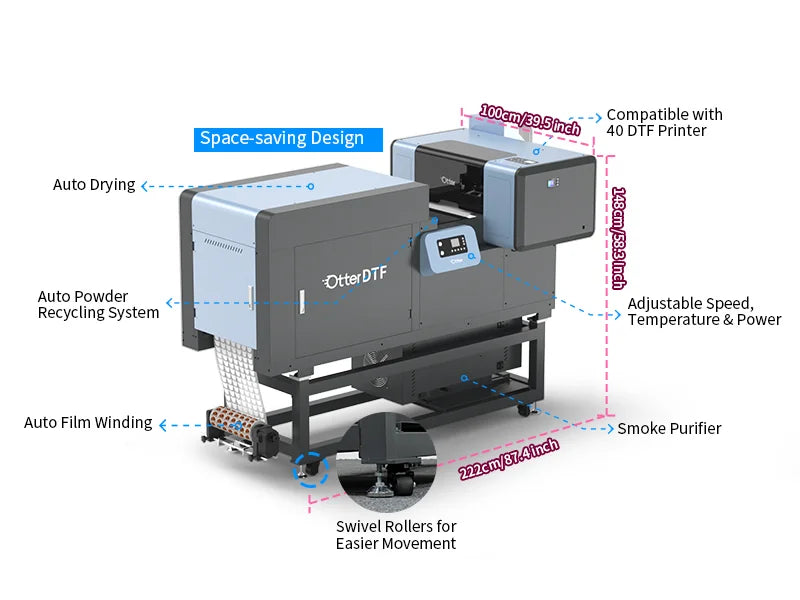

- All-in-one integrated DTF system: printing, powder shaking, and curing

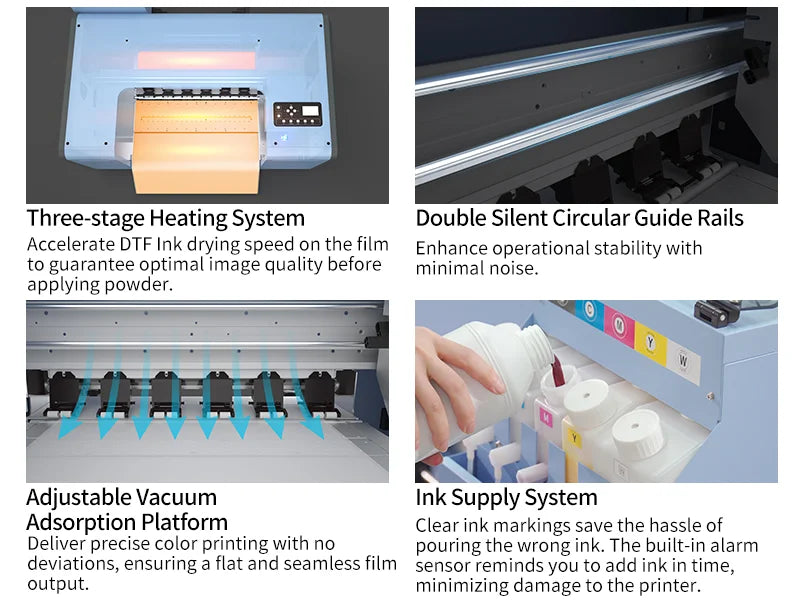

- High-speed, high-resolution printing for sharp details and vivid color

- Compatible with a wide range of fabrics and substrates

- Compact footprint optimized for production environments

- Low-maintenance design with user-friendly interface

- Engineered for continuous operation with reliable performance

Personalization Options:

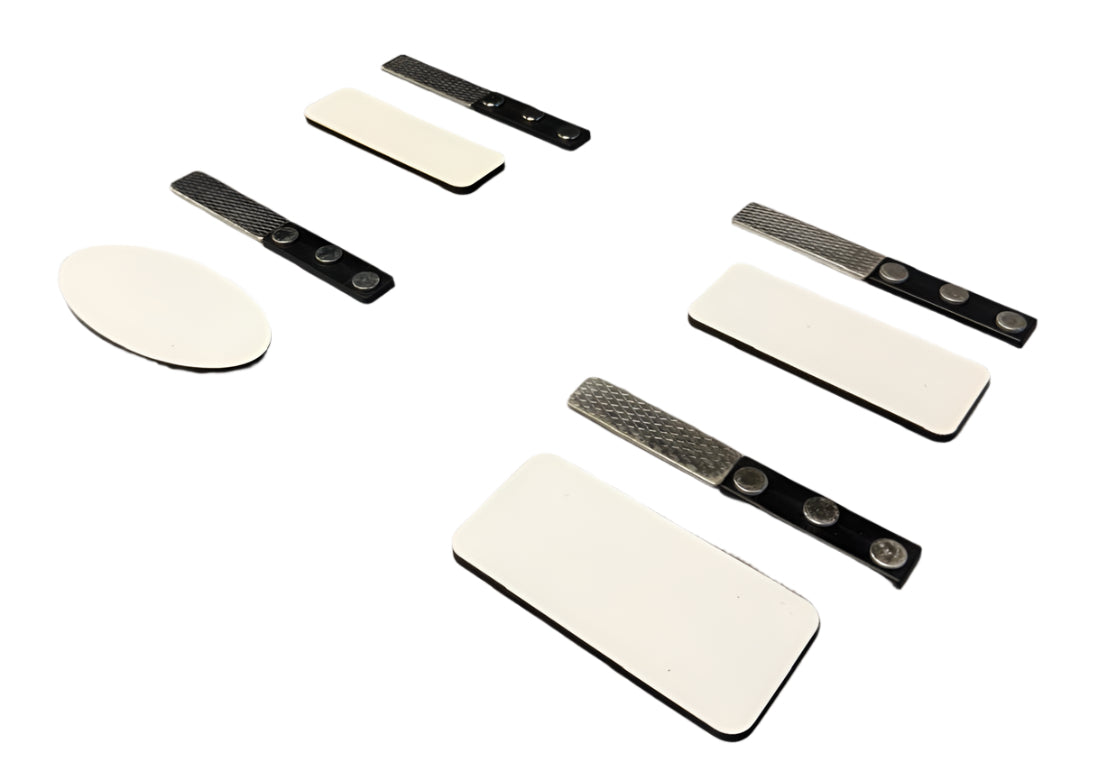

The OtterPro™ enables custom, full-color designs to be transferred onto both light and dark garments. Perfect for t-shirts, hoodies, sportswear, uniforms, tote bags, and promotional products, it offers shops the flexibility to serve multiple markets while delivering durable, professional-quality results.

Printing Compatibility:

- Direct-to-film: PET transfer films for heat-press application

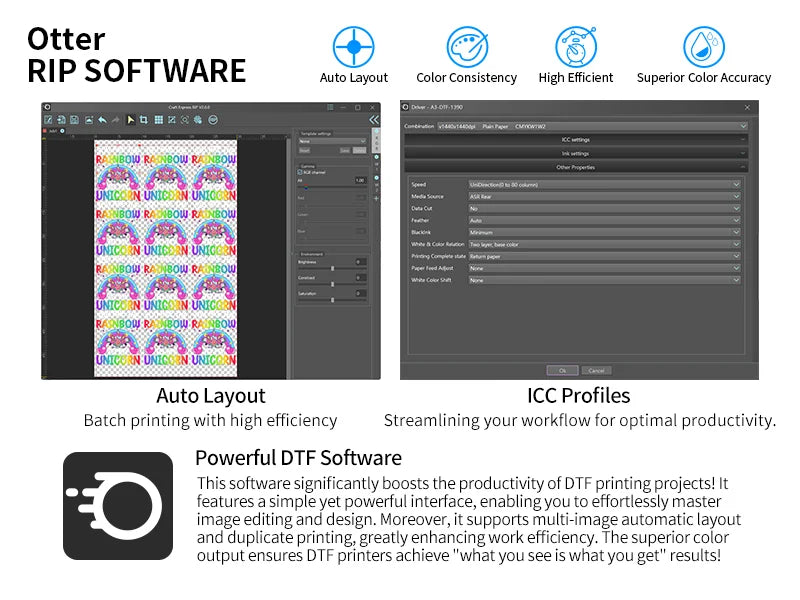

- Compatible with RIP software for color management and workflow optimization

What’s Included – OtterPro S40 Package:

- 2 Sets of OtterPro Ultra Ink (CMYK+W, 2000ml/color)

- 4 Bags OtterPro DTF Powder (1kg each)

- 2 Rolls of DTF Film (42cm x 100m, Double-sided Matte)

- 2 Packs of DTF Film (30cm x 10m)

- Essential replacement parts: dampers, ink tubes, cap top, encoder strip, ink filter, cleaning wipers

- 1L Printhead Cleaning & Protection Fluids

- 6 Hours of Professional Installation & Training

- 6-Month Printhead Warranty (terms apply)

- Optional On-Site Installation

What’s Included – OtterPro S60 Package:

- All items included in the S40 Package

- 6 Bags OtterPro DTF Powder (1kg each)

- 3 Rolls of DTF Film (23.6" x 393.7")

- 1 DTF 4000W Voltage Converter (220V to 110V)

- Extended Ink Tubing for wider print format

Product Specifications:

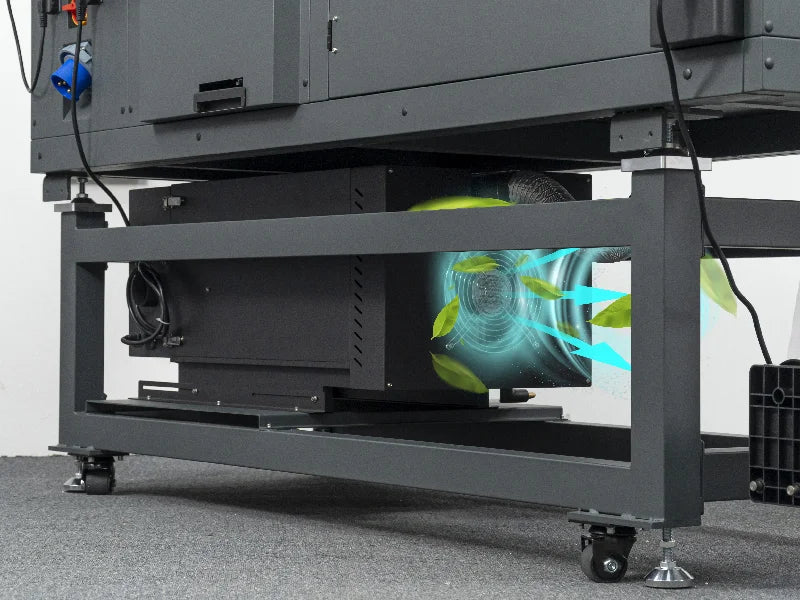

- System Type: All-in-one DTF printer with integrated shaker and oven

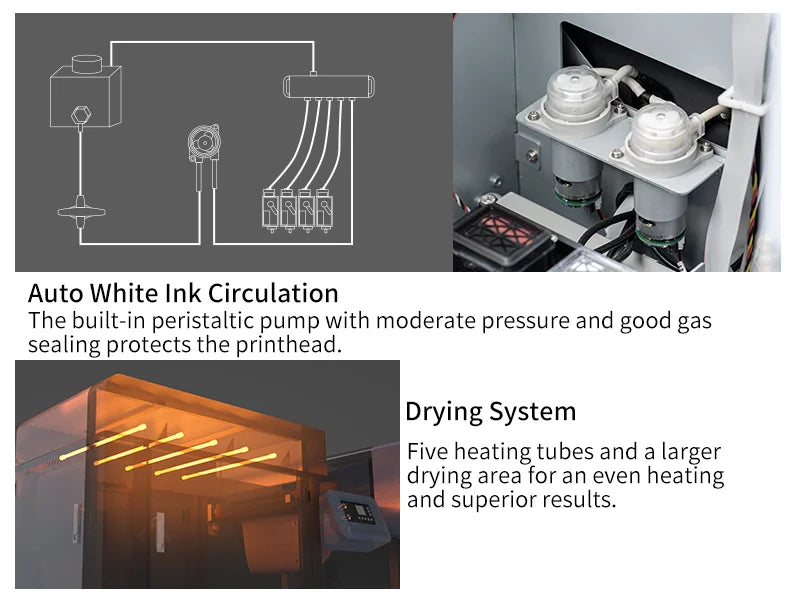

- Ink System: DTF pigment inks (CMYK + White)

- Resolution: High-definition output suitable for fine detail

- Supported Fabrics: Cotton, polyester, blends, nylon, and more

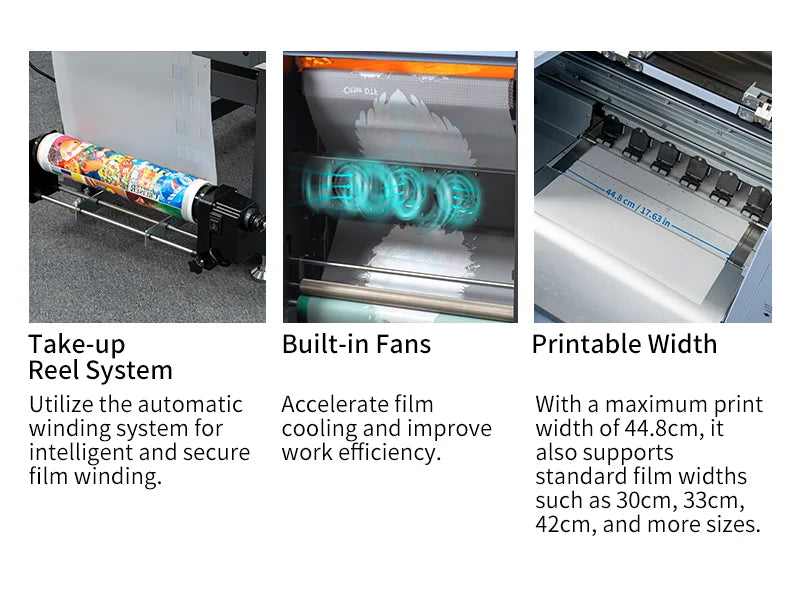

- Workflow: Automatic powder application and curing

- Software: RIP for color profiling and print control

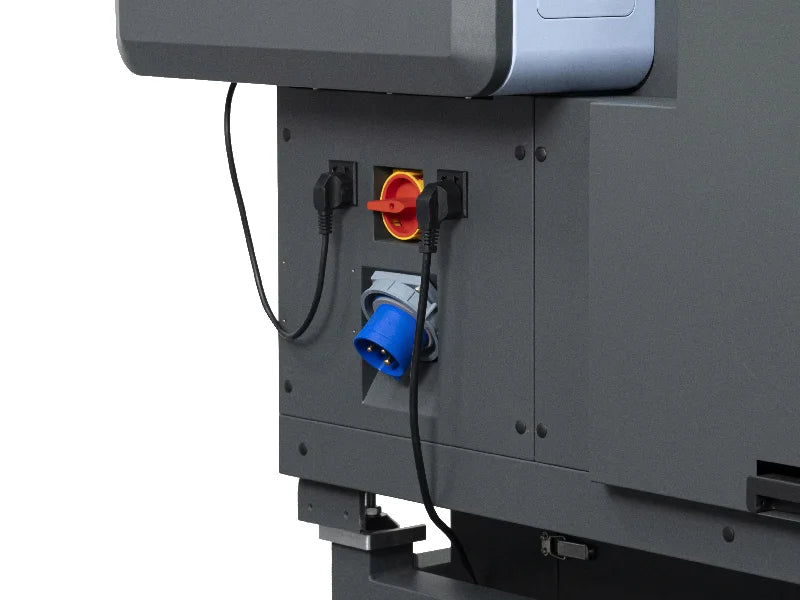

- Power Requirements: As specified in manual

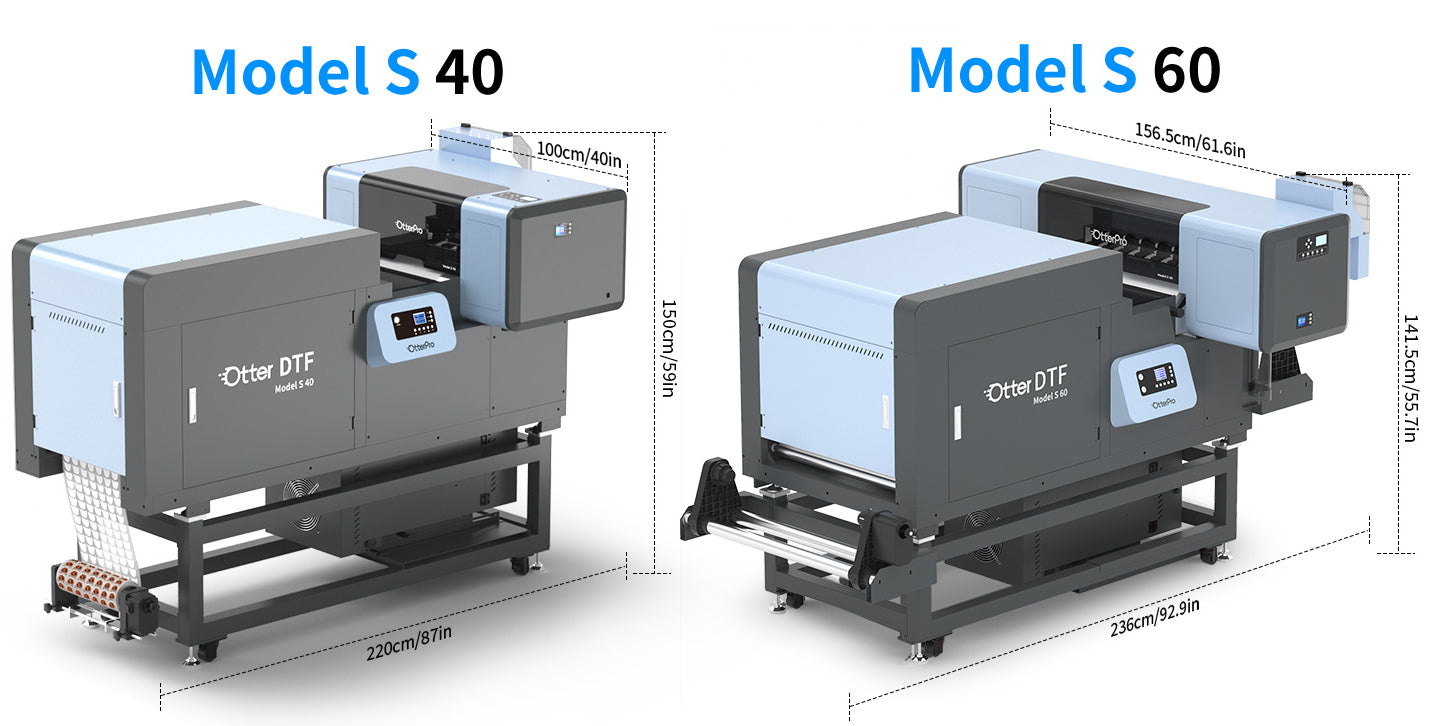

- Dimensions: Compact design for small to medium shops

- Weight: As detailed in brochure specifications

Important Usage Notes:

- Shake white ink daily to prevent settling

- Perform scheduled nozzle checks and cleanings for consistent quality

- Ensure powder is evenly applied and fully cured for durable transfers

- Use recommended PET film sizes for best results

- Maintain proper ventilation when curing prints

Perfect For:

- Shops looking for a complete DTF solution without separate equipment

- Startups entering the custom apparel market

- Businesses scaling into high-volume production with reliable output

- Promotional product suppliers needing versatile decoration options

Handling & Storage Recommendations:

- Store inks in a cool, dry place away from direct sunlight

- Keep PET films flat and free from dust and humidity

- Follow recommended starter supply quantities for balanced workflow (as per guide)

- Regularly clean powder application unit and curing system

- Maintain temperature and humidity control in the workspace

| Dimensions | 220 x 100 x150 cm / 87 x 40 x 59 in (Printer Included) |

|---|---|

| Power Consumption | 2500W MAX±5 |

| Product Specification | Epson i1600 (Model S40) High precise printhead for high productivity and high image quality.Ideal Width for a Perfect Print S40: 0-448mm/l7.6in Stable & Quiet DC Motor Controller Double Silent Circular Guide Rails Steel Body Safe & Intelligent White Ink Auto Circulation Stirring System Automatic Cleaning System Alarm System |

| Voltage | 220V 50Hz |

| Width | 0-448mm/17.6in Max |

| Peel | |

|---|---|

| Equipment | |

| Image | |

| Pressure | |

| Application Temperature | |

| Time |