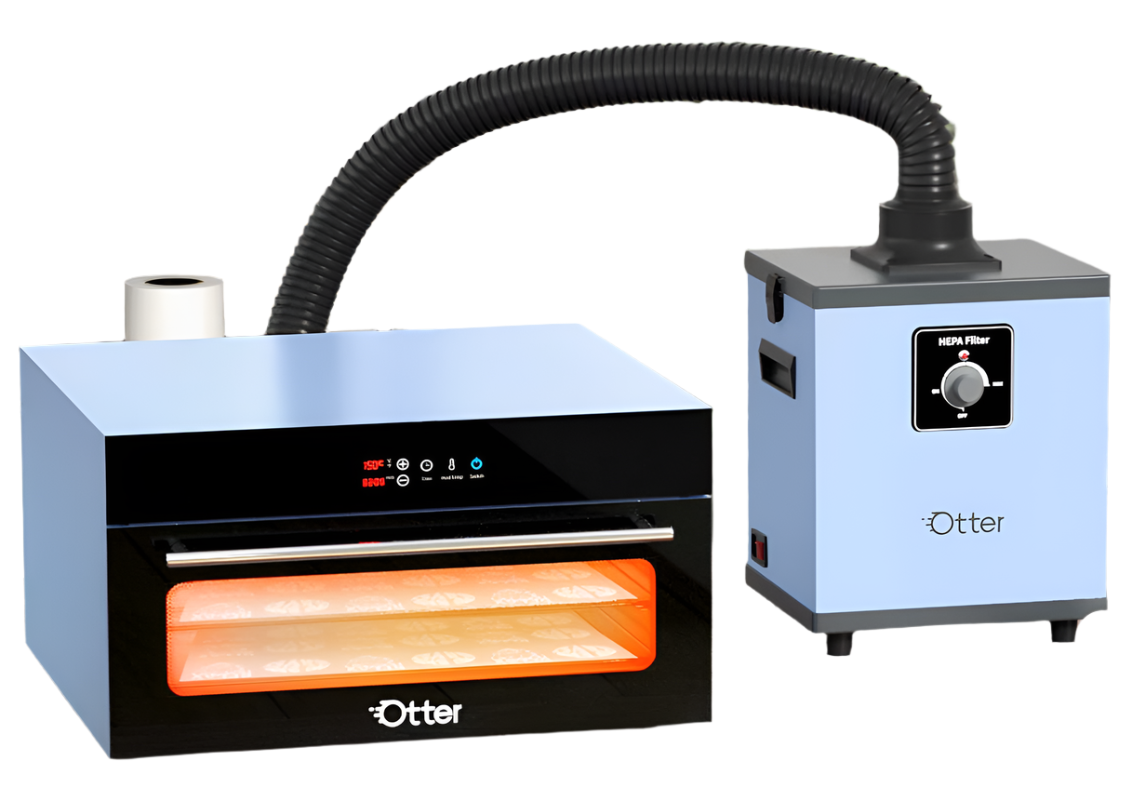

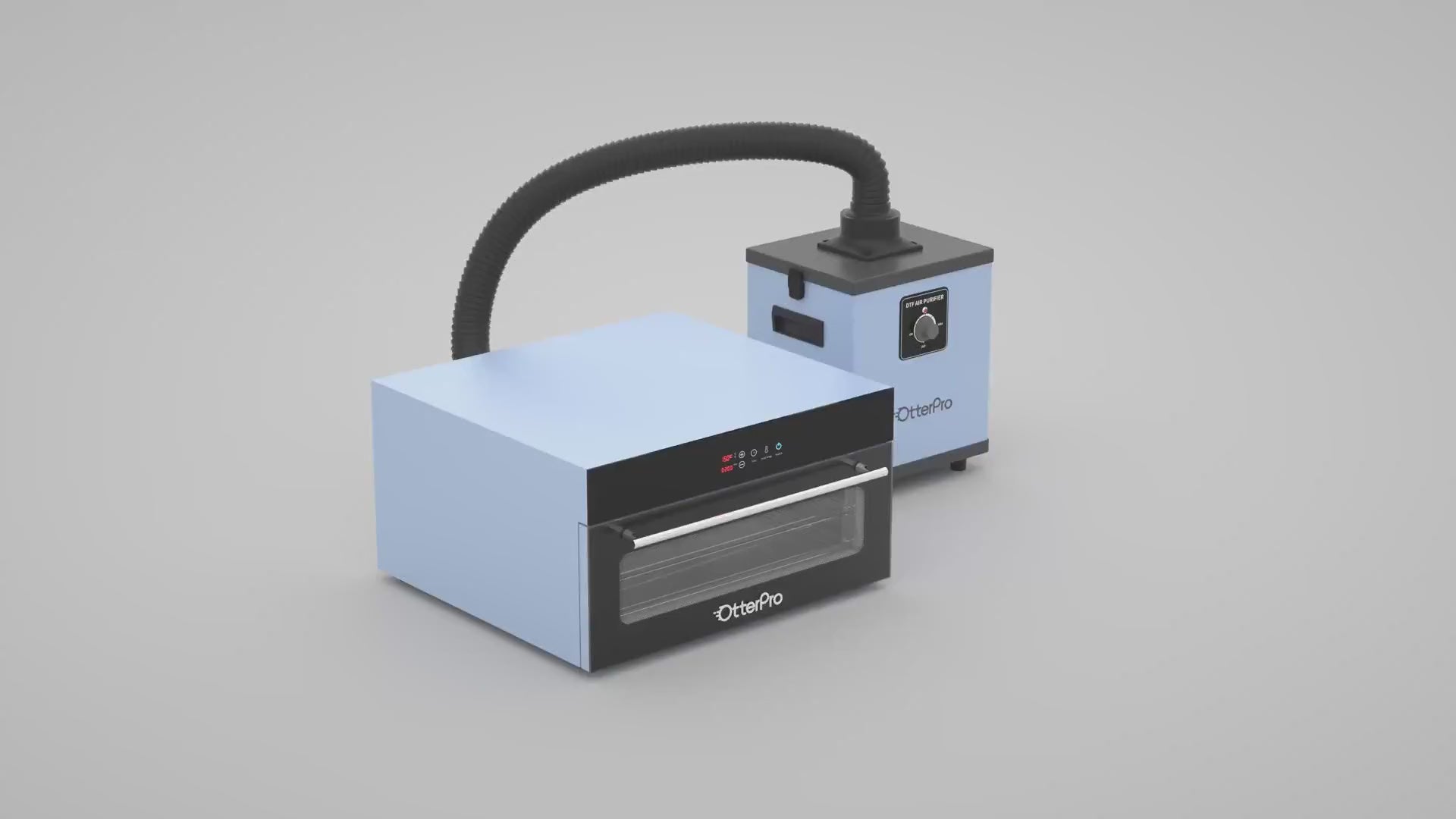

Advanced OtterPro DTF dryer with integrated air purification

The OtterPro DTF Dryer with Purifier is a high-performance tri-layer A3 curing oven equipped with a built-in air purification system. Designed for clean, efficient Direct-to-Film workflows, it ensures sharp, durable transfers alongside a safer, odor-controlled workspace.

With precise hot-air circulation, adjustable heat, and a three-stage filtration purifier, this unit streamlines curing and extraction in one compact desktop system, ideal for studios requiring professional results and air quality management.

Key Features:

- Tri-layer metal rack system handles 3 A3 or 6 A4 DTF films simultaneously for efficient batch processing :contentReference[oaicite:0]{index=0}

- Even hot-air distribution prevents oil return and ensures consistent curing up to 150 °C :contentReference[oaicite:1]{index=1}

- Rear-mounted purifier uses three-layer filter cotton to remove smoke, fumes, and odors during curing :contentReference[oaicite:2]{index=2}

- User-friendly touchscreen interface with intuitive icons for simplified operation :contentReference[oaicite:3]{index=3}

- Compact and light blue desktop form factor – perfect for small studio setups :contentReference[oaicite:4]{index=4}

Personalization Options:

Optimize your curing workflow by combining controlled heat settings with integrated air filtration. Preserve print integrity across textiles, promotional items, and creative designs while eliminating workplace fumes for a healthier production environment.

Printing Compatibility:

- Perfectly matches OtterPro and other DTF printers using A3/A4 film formats :contentReference[oaicite:5]{index=5}

- Works with classic hot-air DTF curing for polyester, coated substrates, and versatile finishing applications

- Built-in purifier supports safe operation in compact or shared creative spaces

Product Specifications:

- Temperature range: 40 – 150 °C (104 – 302 °F) :contentReference[oaicite:6]{index=6}

- Capacity: 3 A3 sheets or 6 A4 sheets via tri-layer racks; internal volume approx. 32 L :contentReference[oaicite:7]{index=7}

- Dimensions: 21.4" × 23.8" × 11.9" (54.4 × 60.3 × 30.3 cm) :contentReference[oaicite:8]{index=8}

- Power: Approximately 1450 W :contentReference[oaicite:9]{index=9}

- Purifier power: ~150 W; includes 1.5 m hose, clamps, and 3 oil-absorbing filter sheets :contentReference[oaicite:10]{index=10}

- Weight: Approximately 14.3 kg (dryer), 9.5 kg (purifier) :contentReference[oaicite:11]{index=11}

- Voltage: Supports 110 V / 220 V configurations :contentReference[oaicite:12]{index=12}

- Pack Quantity: 1 unit (dryer + purifier combo)

Important Usage Notes:

- Monitor temperature closely—max 150 °C prevents oil return and ensures crisp, smudge-free prints :contentReference[oaicite:13]{index=13}

- Allow complete cooling before accessing rack layers to preserve curing quality

- Replace filter cotton regularly to maintain airflow and purification efficiency :contentReference[oaicite:14]{index=14}

- Connect purifier securely via hose and clamps; ensure proper ventilation during operation

Perfect For:

- Print studios needing streamlined batch curing with environmental safety

- Small to medium-scale creative operations with limited space requiring clean air control

- Businesses focused on consistent, vibrant DTF transfers that uphold print and air quality standards

Handling & Storage Recommendations:

- Place on stable, heat-resistant surface away from moisture

- Allow full cooling before cleaning or moving device

- Store purifier filters in a dry, clean area; avoid crushing or bending filter media

| Peel | |

|---|---|

| Equipment | |

| Image | |

| Pressure | |

| Application Temperature | |

| Time |