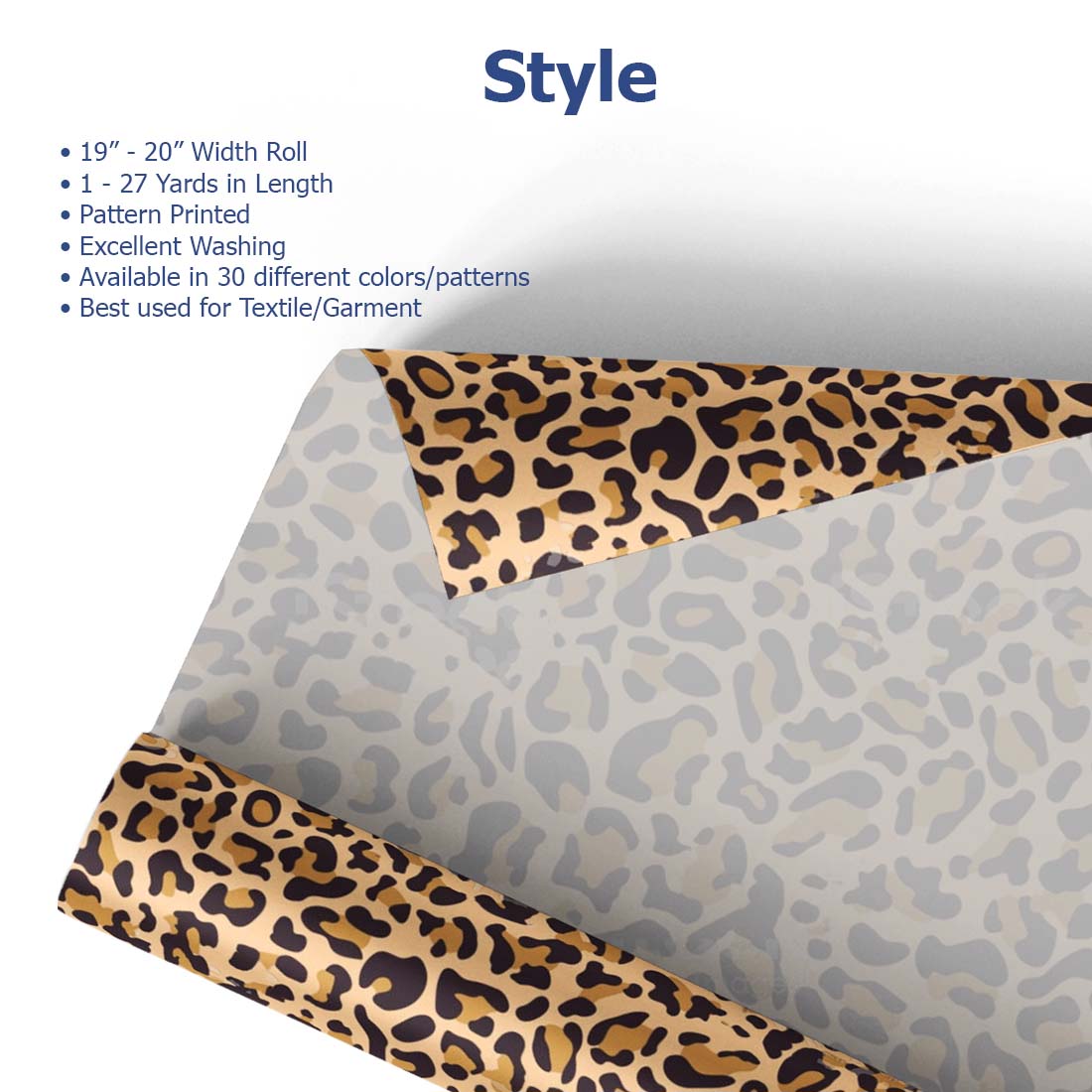

Heat transfer vinyl (HTV) is a versatile, adhesive-backed material used for custom apparel and various projects. Made from a blend of polyurethane and PVC, HTV can be cut into intricate designs and applied to fabrics, wood, metal, and more using a heat press. Its heat-activated adhesive allows for permanent bonding, making it ideal for creating personalized items like T-shirts and home decor with a wide array of colors and patterns.

- 1

- 2

Achieve precision and versatility with Joto's MultiCut™ Heat Transfer Vinyls, perfect for logos, numbers, names, and lettering on various fabrics. Our vibrant vinyls allow for easy customization of sports jerseys, T-shirts, and more, making them ideal for crafters, small businesses, and custom apparel professionals.

What is Heat Transfer Vinyl?

How to Use Heat Transfer Vinyl

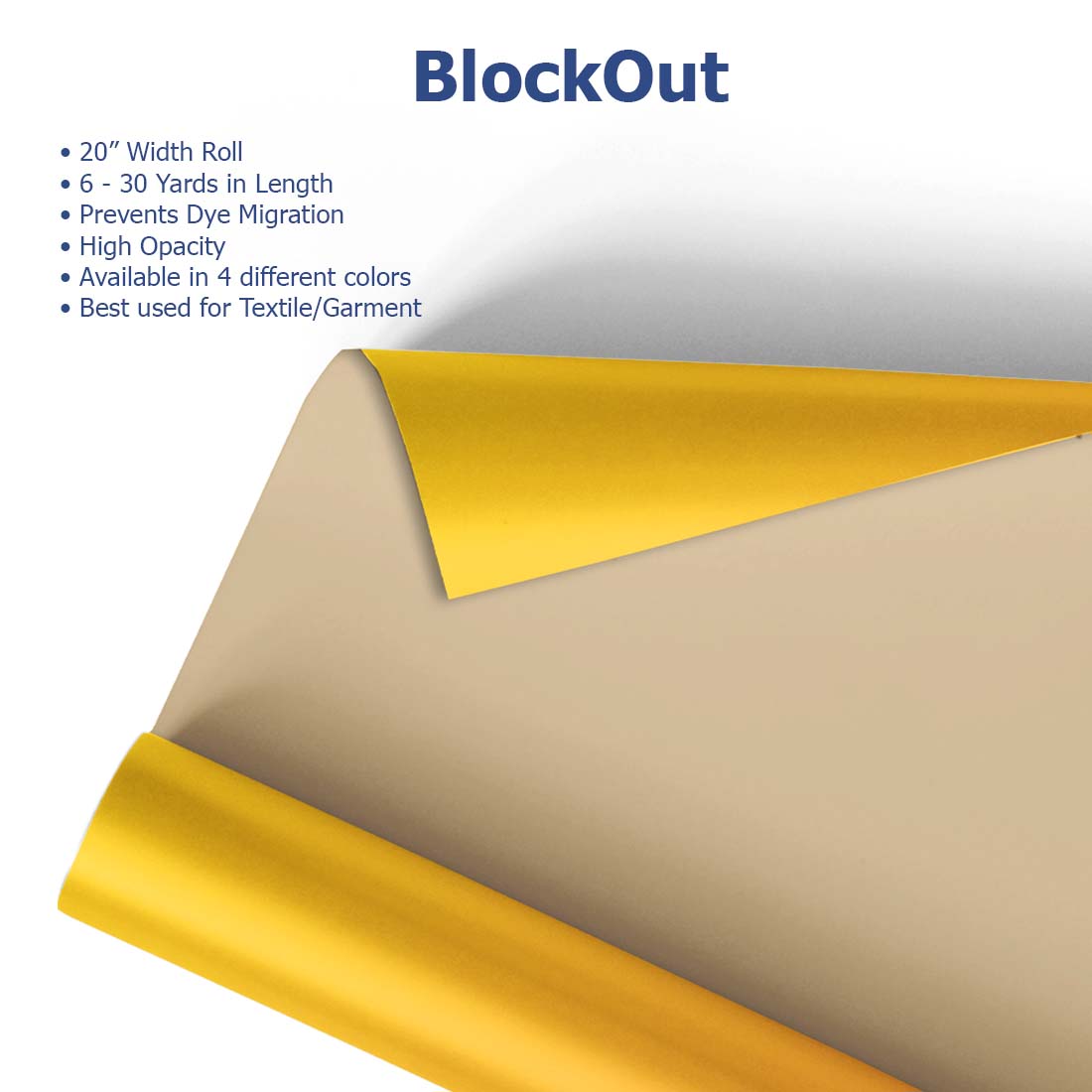

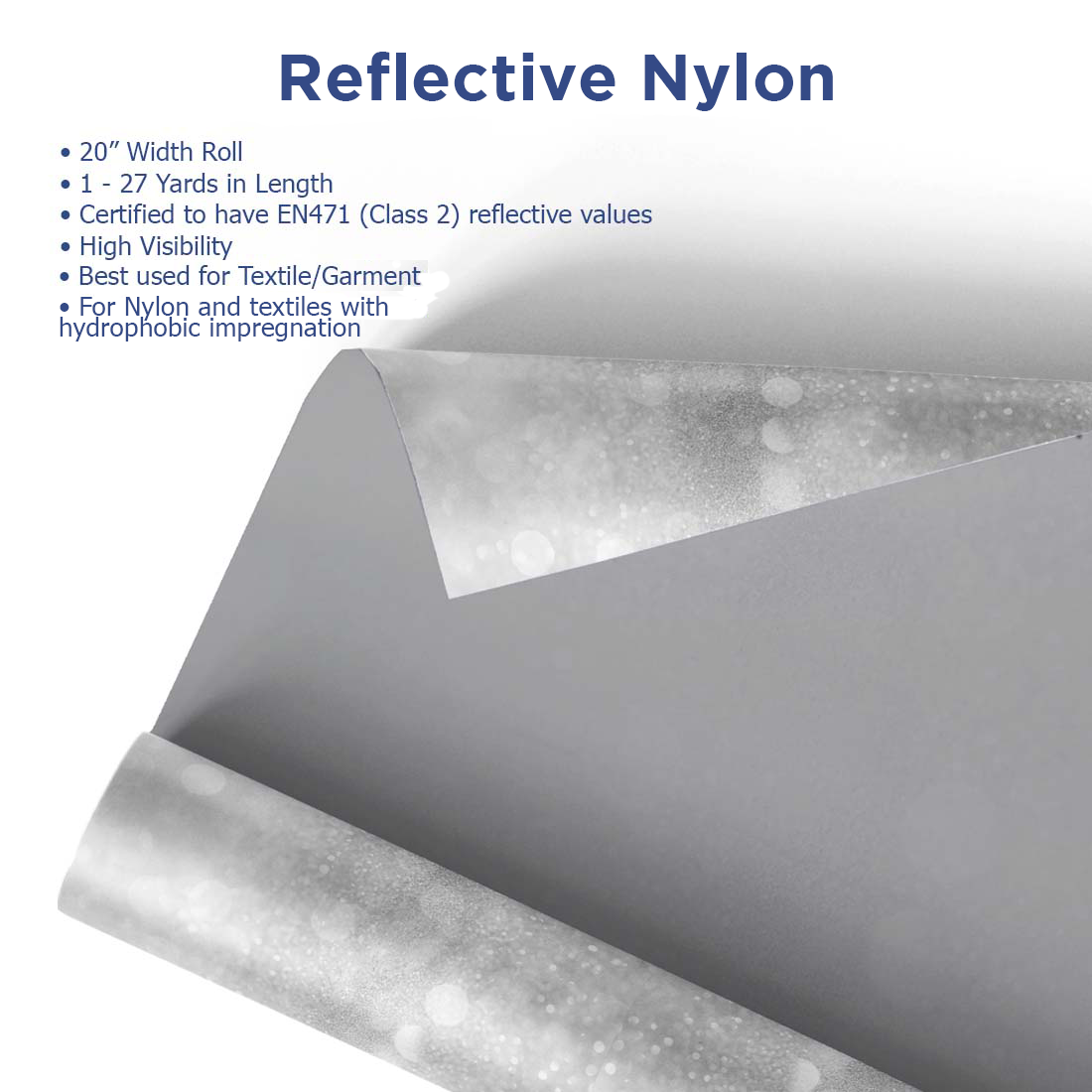

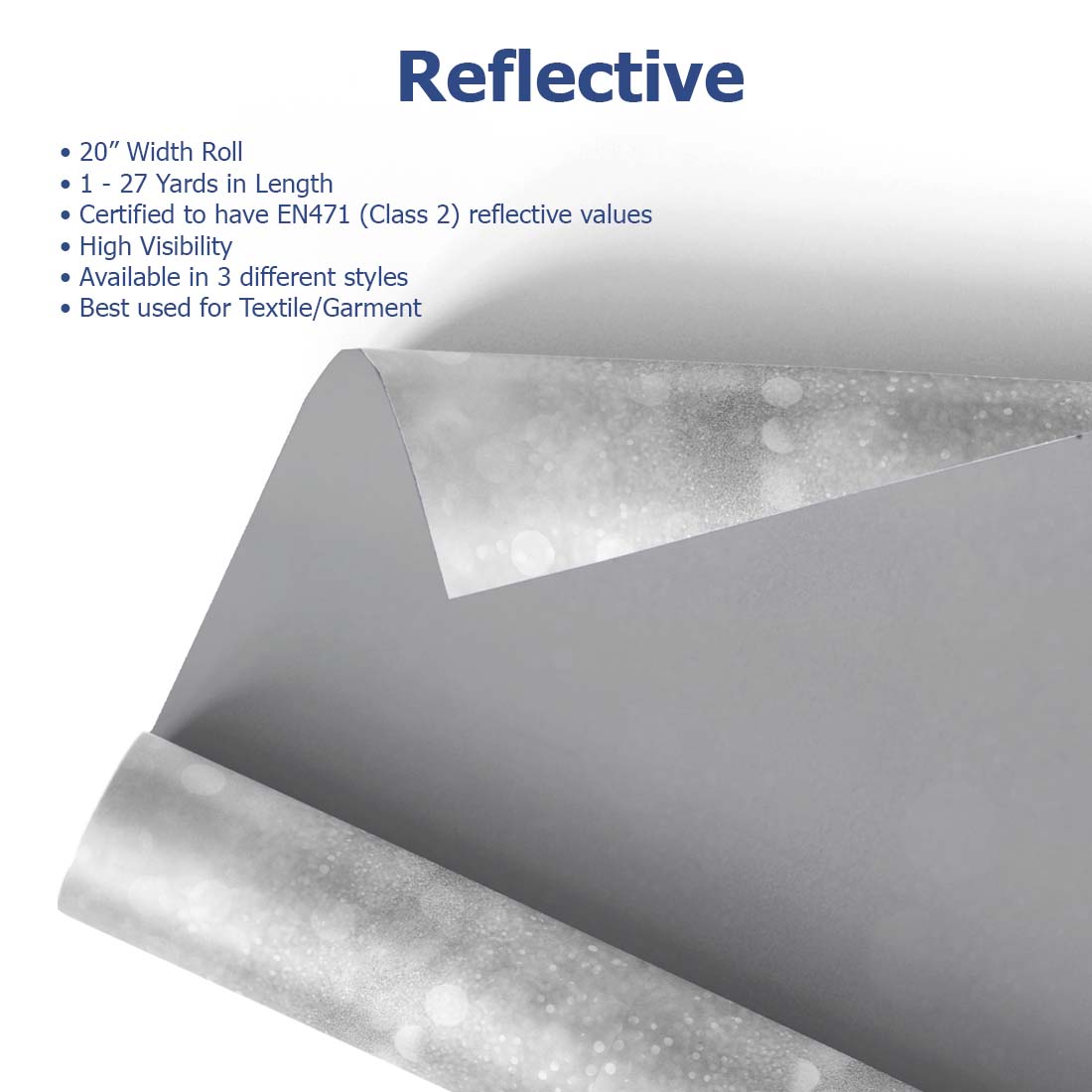

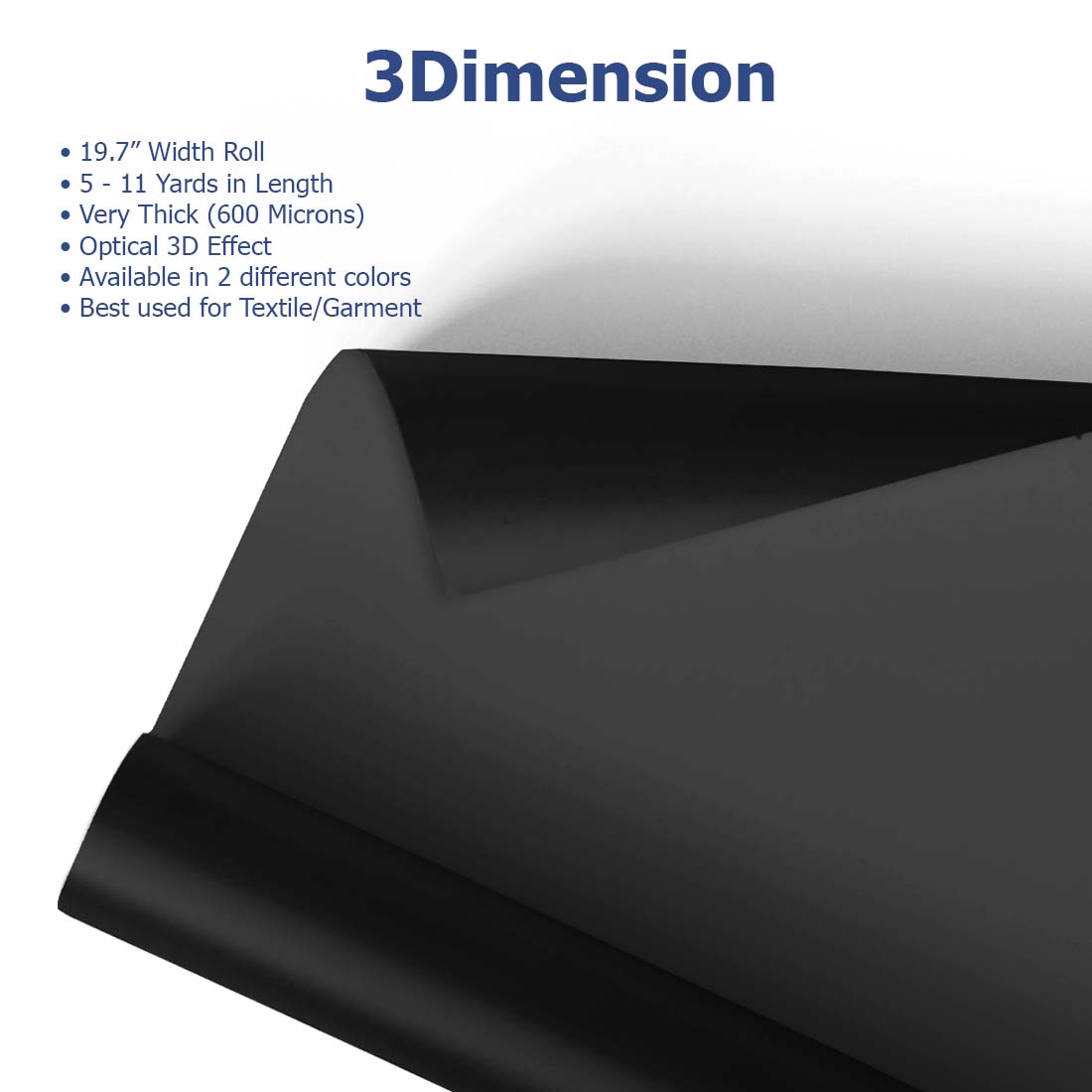

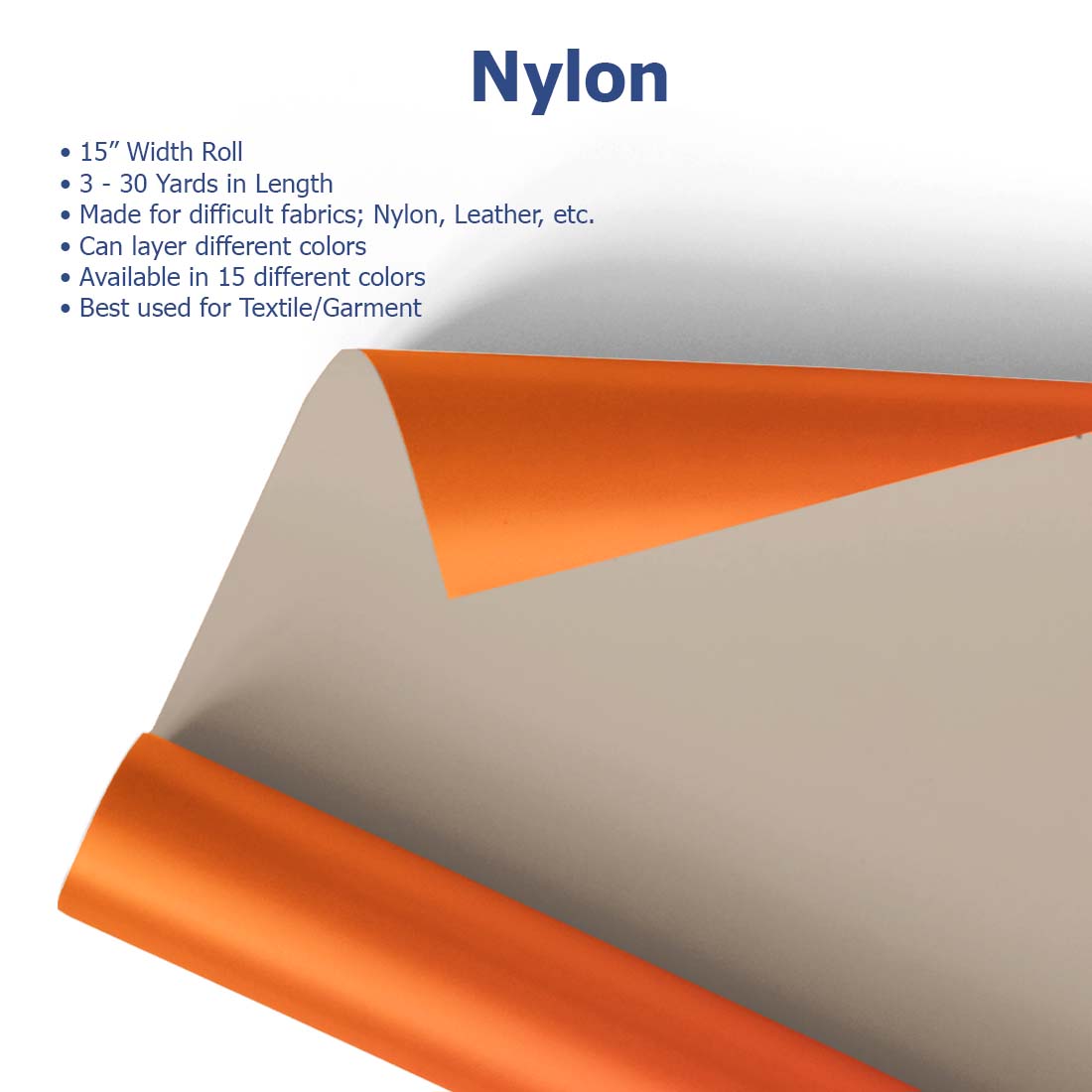

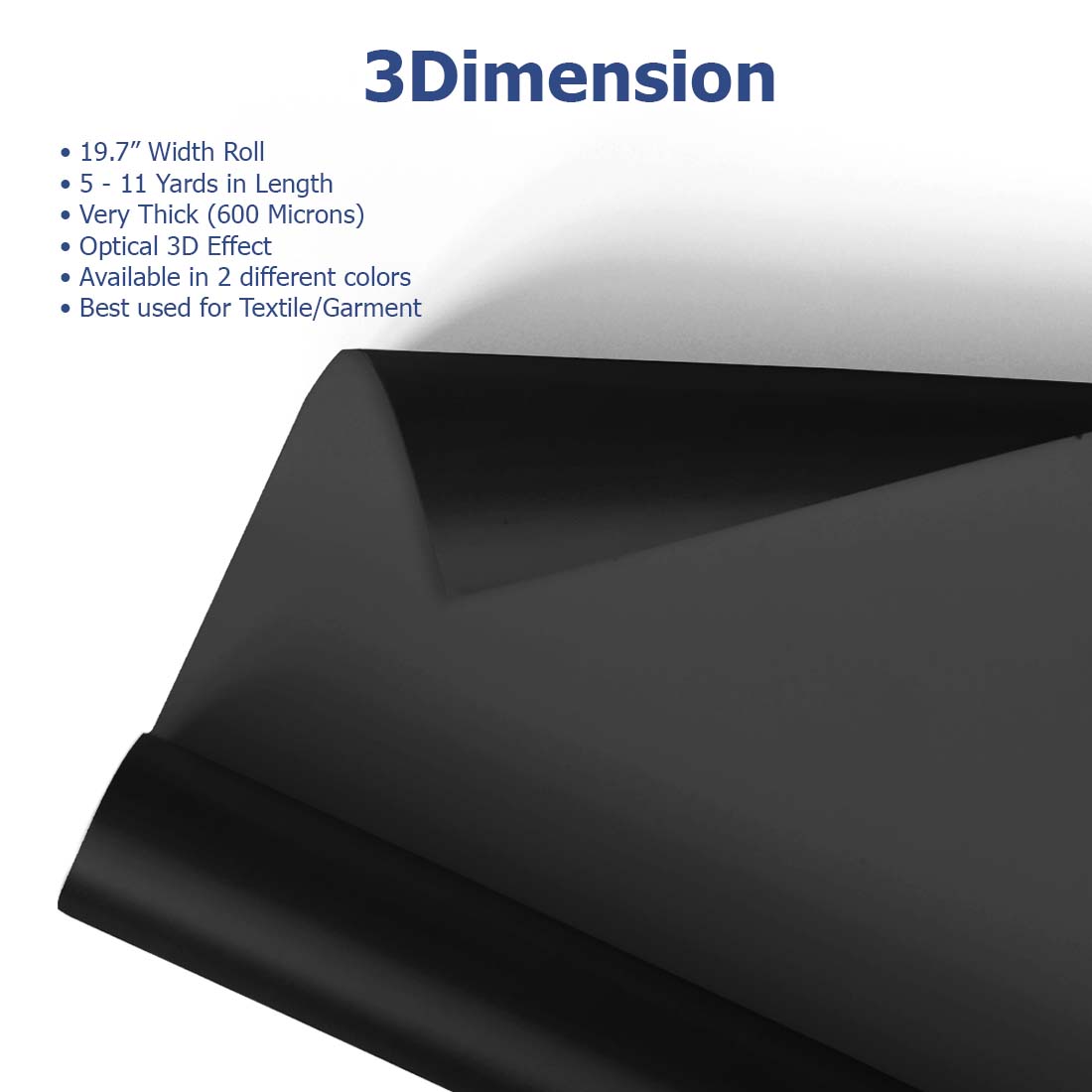

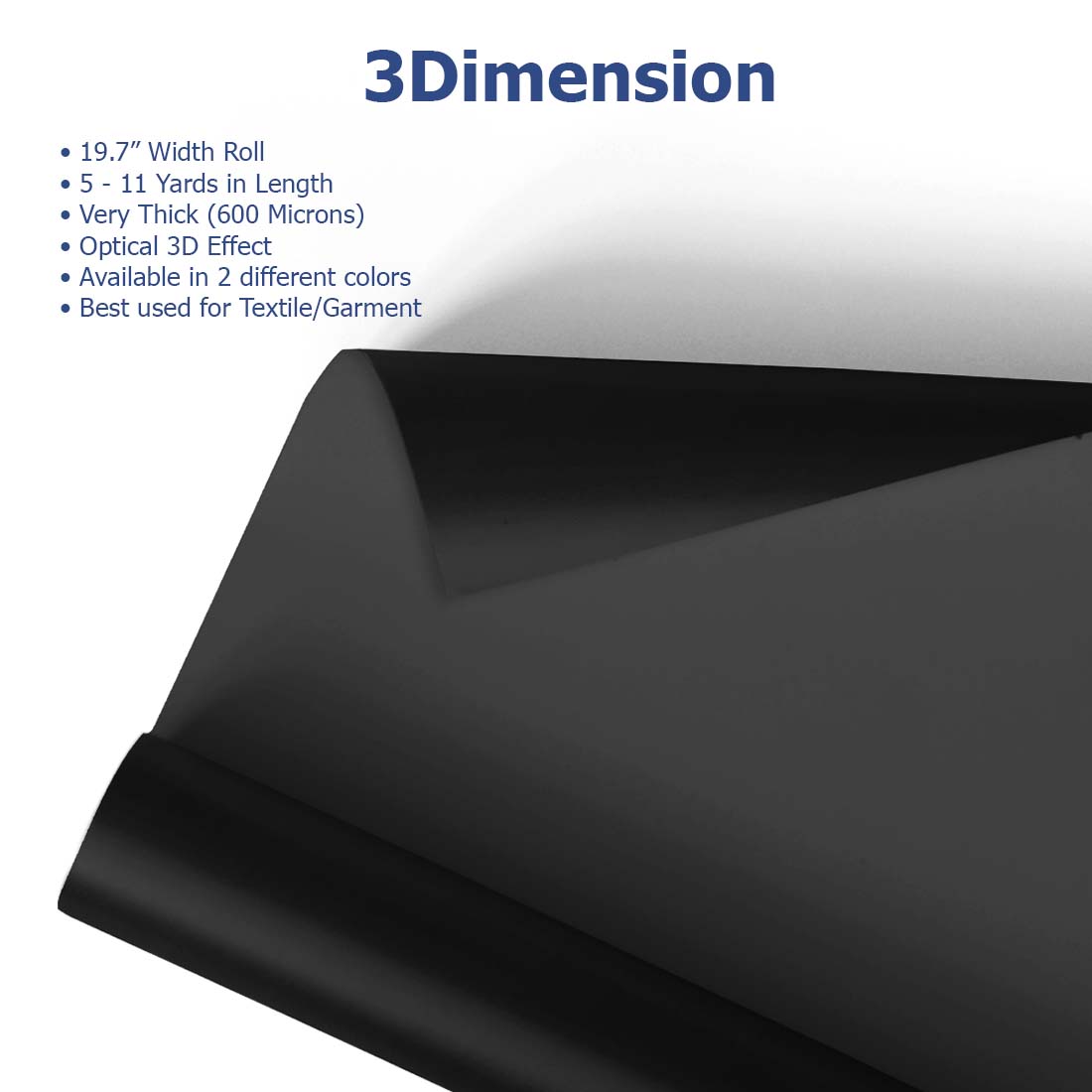

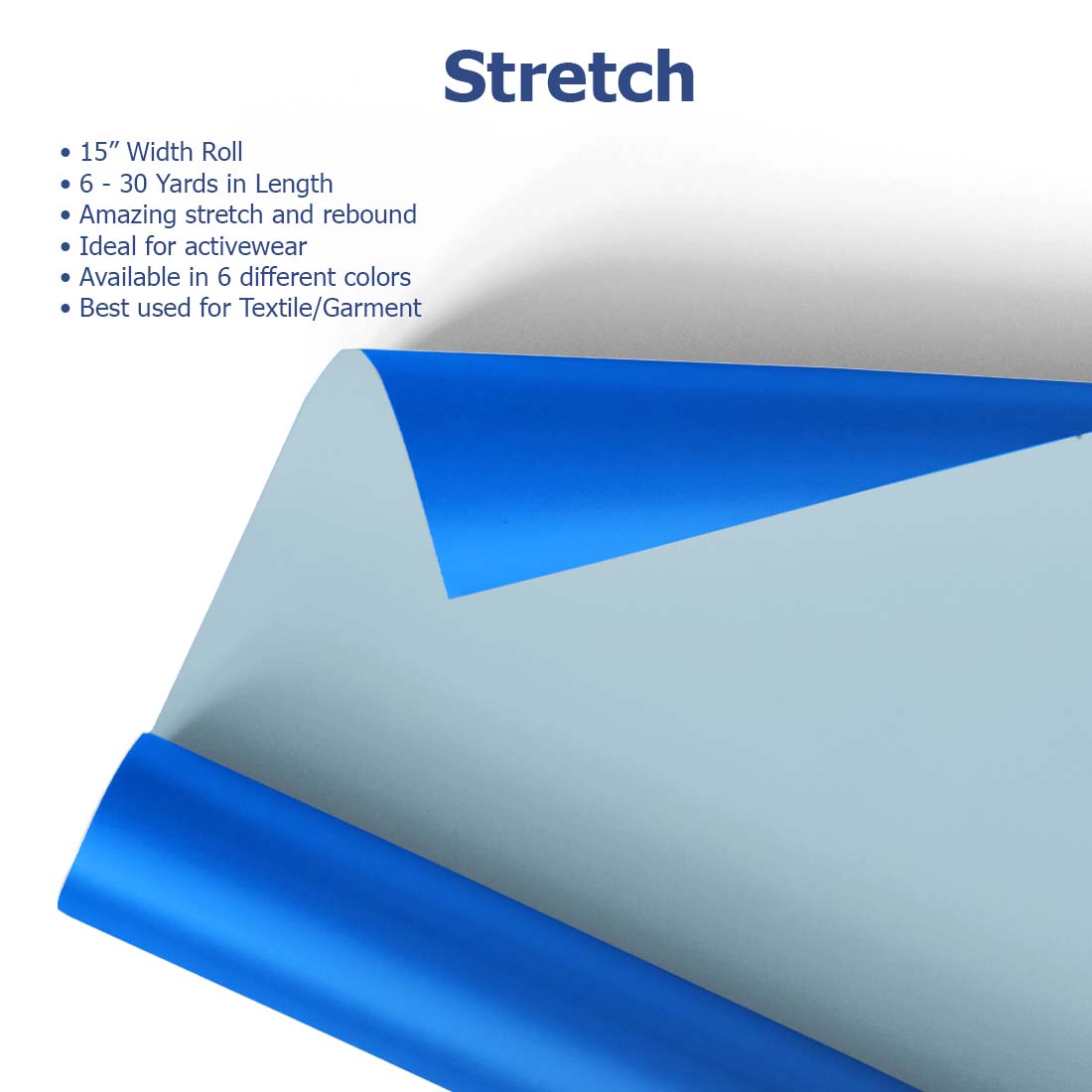

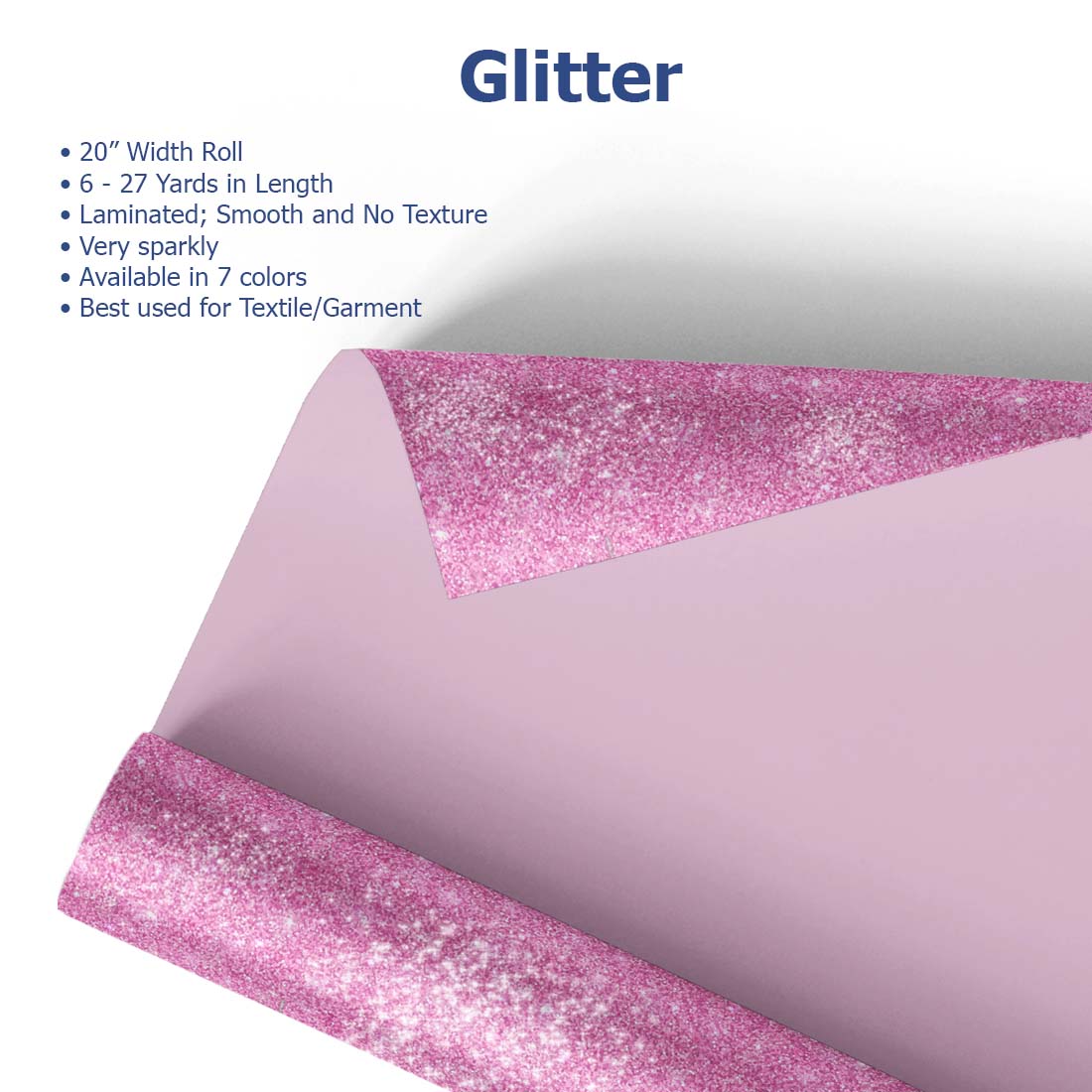

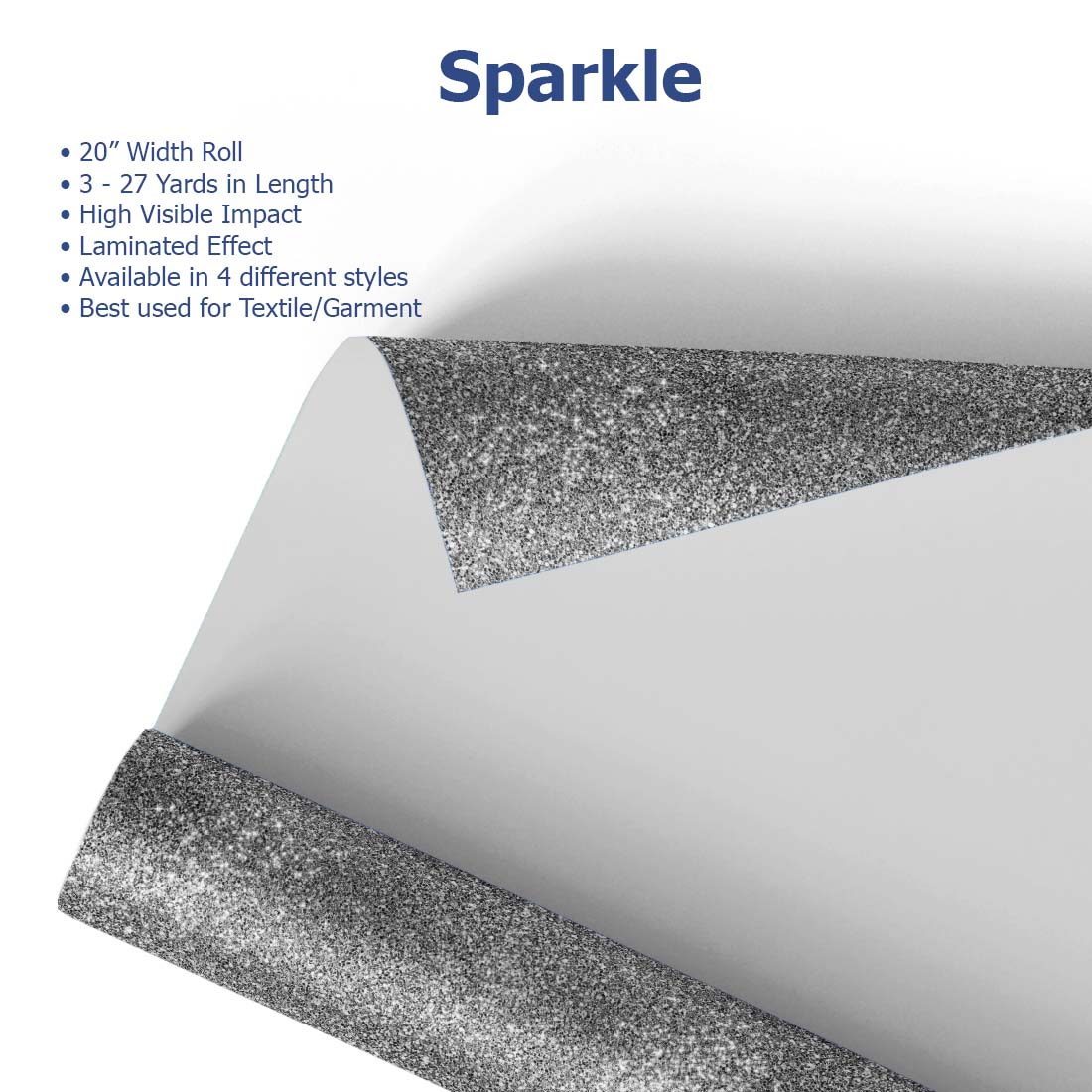

Types of Heat Transfer Vinyl

Heat Transfer Vinyl Designs

What is needed for heat transfer vinyl?

Is printable HTV the same as sublimation?

Will heat transfer vinyl peel off?

Can you overheat heat transfer vinyl?